Seamless Steel pipe High Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Steel pipe High Quality and Best Price:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless Steel pipe High Quality and Best Price:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Steel pipe High Quality and Best Price Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Steel pipe High Quality and Best Price:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

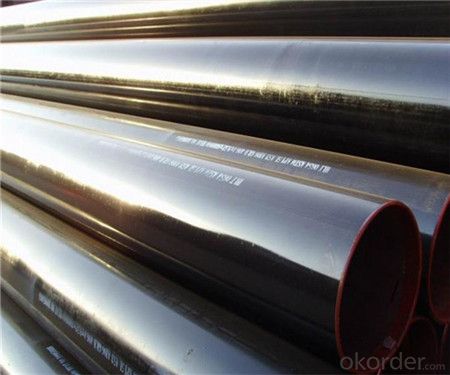

6、Seamless Steel pipe High Quality and Best Price Images:

- Q: How are steel pipes insulated for thermal applications?

- Steel pipes are commonly insulated for thermal applications using various materials such as fiberglass, mineral wool, or foam insulation. These insulating materials are typically wrapped around the steel pipes to create a protective barrier that reduces heat transfer. Additionally, a vapor barrier may be installed to prevent moisture condensation. This insulation helps to maintain the desired temperature of the fluid or gas being transported through the pipes and prevents energy loss.

- Q: How do steel pipes perform in extreme weather conditions?

- Steel pipes are highly resilient and perform exceptionally well in extreme weather conditions. They have excellent resistance to corrosion, impact, and temperature variations, making them ideal for withstanding harsh environments such as extreme heat, cold, and heavy rainfall. Moreover, steel pipes are known for their durability and strength, ensuring that they can withstand the forces exerted by high winds, snow, and even seismic activities. Overall, steel pipes are a reliable choice for various applications in extreme weather conditions.

- Q: What are the different methods of non-destructive testing for steel pipes?

- The different methods of non-destructive testing for steel pipes include visual inspection, ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. These methods are used to detect defects or abnormalities in the pipes without causing any damage. Visual inspection involves a thorough visual examination of the pipe's surface. Ultrasonic testing uses high-frequency sound waves to identify internal flaws or thickness measurements. Magnetic particle testing detects surface and near-surface defects by applying a magnetic field and inspecting for magnetic particles. Liquid penetrant testing involves applying a liquid dye to the surface and inspecting for any visible indications of defects. Radiographic testing uses X-rays or gamma rays to capture images that reveal internal defects or flaws in the steel pipes.

- Q: Can steel pipes be used for conveying potable water?

- Yes, steel pipes can be used for conveying potable water. However, there are some considerations and precautions that need to be taken into account. Steel pipes are strong and durable, making them suitable for transporting water over long distances. They are also resistant to corrosion and can withstand high pressure. To ensure the safety and quality of the water being transported, it is important to use pipes that are specifically designed and manufactured for potable water applications. These pipes are often coated or lined with materials that prevent the leaching of contaminants into the water, such as epoxy or cement mortar lining. Additionally, regular maintenance and inspections should be conducted to prevent the buildup of sediments or rust that could affect the water quality. It is worth noting that steel pipes can be more expensive compared to other materials like plastic or copper. However, their longevity and reliability make them a cost-effective choice in the long run. It is also important to comply with local regulations and standards regarding the use of steel pipes for conveying potable water to ensure the health and safety of consumers.

- Q: What are the different methods of bending steel pipes?

- There are several methods of bending steel pipes, including manual bending, rotary draw bending, mandrel bending, and hydraulic pipe bending.

- Q: Can steel pipes be used for geothermal applications?

- Yes, steel pipes can be used for geothermal applications. Steel pipes have high strength and durability, which makes them suitable for handling the high temperatures and pressures involved in geothermal systems. Additionally, steel pipes are resistant to corrosion and can withstand the harsh conditions found deep underground, making them a reliable choice for transporting geothermal fluids.

- Q: Are steel pipes suitable for chemical processing plants?

- Steel pipes are commonly used in chemical processing plants due to their excellent strength, durability, and resistance to corrosion. Steel pipes, especially those made of stainless steel or alloy steel, can withstand high temperatures, pressure, and the corrosive effects of various chemicals. This makes them suitable for transporting and containing different types of chemicals in a safe and efficient manner. Additionally, steel pipes are easy to install, maintain, and repair, making them a cost-effective choice for chemical processing plants. However, it is important to select the appropriate type of steel and consider factors such as the specific chemicals being processed, the operating conditions, and any potential risks or compatibility issues. Regular inspections and maintenance are also essential to ensure the integrity and performance of steel pipes in chemical processing plants.

- Q: How do steel pipes compare to other pipe materials like PVC or copper?

- Steel pipes have several advantages over other pipe materials like PVC or copper. Firstly, steel pipes are incredibly strong and durable, making them suitable for high-pressure applications and long-term use. They have a higher resistance to cracking or breaking, which is especially beneficial in demanding environments. Secondly, steel pipes have excellent heat resistance, making them ideal for transporting hot fluids. On the other hand, PVC pipes are more lightweight, cost-effective, and easy to install, making them suitable for non-pressure applications. Copper pipes are known for their corrosion resistance and ability to handle high temperatures, but they are typically more expensive. Overall, the choice between steel, PVC, or copper pipes depends on the specific requirements of the application, considering factors like pressure, temperature, cost, and ease of installation.

- Q: What is the difference between steel pipes and concrete-lined pipes?

- The main difference between steel pipes and concrete-lined pipes lies in their composition and structural properties. Steel pipes are primarily made of steel, which provides strength, durability, and resistance to corrosion. On the other hand, concrete-lined pipes are steel pipes that have been coated with a layer of concrete. This concrete lining adds an extra layer of protection against corrosion and also provides additional structural stability. Concrete-lined pipes are commonly used in applications where protection against corrosion and abrasion is crucial, such as in water distribution systems or sewage pipelines. In contrast, steel pipes are often used in various industries where strength and durability are vital, such as oil and gas pipelines or structural applications.

- Q: Where is a steel pipe casing usually used?

- The casing, usually used in the basement construction, to protect the pipeline or convenient pipeline installation hoops.

Send your message to us

Seamless Steel pipe High Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords