GR.B Carbon Seamless Steel Pipe With Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

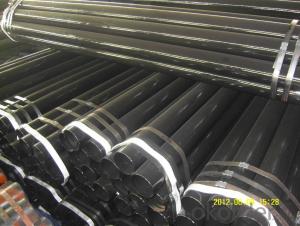

5.Product pictures

6.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How are steel pipes insulated for thermal applications?

- Steel pipes are commonly insulated for thermal applications using various materials such as fiberglass, mineral wool, or foam insulation. These insulating materials are typically wrapped around the steel pipes to create a protective barrier that reduces heat transfer. Additionally, a vapor barrier may be installed to prevent moisture condensation. This insulation helps to maintain the desired temperature of the fluid or gas being transported through the pipes and prevents energy loss.

- Q: What is the difference between steel pipes and PVC-O pipes?

- Steel pipes and PVC-O pipes differ in their composition, strength, and durability. Steel pipes are made from a combination of iron and carbon, making them extremely strong and resistant to high-pressure applications. However, they are susceptible to corrosion and may require regular maintenance. On the other hand, PVC-O pipes are made from a specialized form of polyvinyl chloride, which enhances their strength and durability while being corrosion-resistant. PVC-O pipes are also lighter, easier to install, and have a longer lifespan compared to steel pipes. Overall, while steel pipes excel in strength, PVC-O pipes offer a more cost-effective and durable solution for various plumbing and industrial applications.

- Q: How are steel pipes measured and labeled?

- Steel pipes are typically measured and labeled based on their nominal pipe size (NPS), which refers to the inner diameter of the pipe. This measurement is expressed in inches or millimeters. Additionally, steel pipes are often labeled with their schedule or wall thickness, which is represented by a numerical value. The labeling also includes the pipe material, such as carbon steel or stainless steel, and may include other specifications and markings as required by industry standards and regulations.

- Q: Can steel pipes be used for underground water supply?

- Yes, steel pipes can be used for underground water supply. However, it is important to consider factors such as corrosion resistance and proper coating to protect the pipes from potential degradation caused by the surrounding soil and water chemistry. Additionally, regular maintenance and inspections are necessary to ensure the longevity and integrity of the steel pipes in underground water supply systems.

- Q: How are steel pipes measured and sized?

- Steel pipes are measured and sized based on their diameter and wall thickness. The standard unit for measuring steel pipes is the nominal pipe size (NPS), which is a North American set of standard sizes for pipes. The NPS is based on the internal diameter (ID) of the pipe, while the wall thickness is specified by the schedule number. The schedule number indicates the thickness of the pipe walls, with higher numbers representing thicker walls. Additionally, steel pipes can also be measured and sized using outside diameter (OD) and wall thickness in millimeters or inches.

- Q: How are steel pipes insulated for thermal efficiency?

- Steel pipes are insulated for thermal efficiency by adding a layer of insulation material around them. This insulation helps to reduce heat transfer through the pipes, preventing energy loss and maintaining the desired temperature.

- Q: What are the safety measures to consider when working with steel pipes?

- When working with steel pipes, it is important to consider several safety measures. Firstly, wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots is crucial to protect against potential injuries. Secondly, ensuring proper ventilation in the work area is important to avoid inhalation of harmful gases or fumes. Additionally, practicing proper lifting techniques and using mechanical aids when handling heavy pipes can prevent strains or back injuries. It is also essential to be cautious of sharp edges or protruding objects on the pipes and to secure them properly to prevent accidents. Lastly, following established safety protocols, such as conducting regular inspections and adhering to lockout/tagout procedures, helps minimize the risk of accidents or equipment malfunctions.

- Q: How are steel pipes used in the renewable energy industry?

- Steel pipes are widely used in the renewable energy industry for various purposes. They are commonly used in the construction of wind turbine towers, where they provide structural support and stability. Steel pipes are also used in the installation of solar panel systems, serving as a reliable conduit for transporting fluids, such as water or heat transfer fluids, within the system. Additionally, steel pipes are utilized in the transportation of renewable energy resources, such as natural gas or hydrogen, as they offer durability and strength to withstand high-pressure conditions.

- Q: What are the factors to consider while selecting steel pipes for a project?

- When selecting steel pipes for a project, there are several important factors to consider. These factors include the material composition of the steel, the pipe dimensions, the intended application, the environmental conditions, and the budget. 1. Material Composition: The material composition of the steel pipes is crucial as it determines the pipes' strength, corrosion resistance, and durability. Common types of steel used for pipes include carbon steel, stainless steel, and alloy steel. Each type has its own set of properties and is suitable for different applications. 2. Pipe Dimensions: The dimensions of the steel pipes, such as diameter and wall thickness, should be carefully considered. The pipe dimensions must be compatible with the project requirements and the system in which the pipes will be installed. It is essential to ensure that the selected pipes can handle the required flow rates and pressures. 3. Intended Application: The specific application of the steel pipes should be thoroughly assessed. Different projects may require pipes with varying characteristics, such as heat resistance, pressure resistance, or the ability to transport specific substances like gas, oil, or water. Understanding the application requirements will help in choosing the appropriate type of steel pipes. 4. Environmental Conditions: The environmental conditions in which the pipes will be installed must be evaluated. Factors such as temperature variations, exposure to moisture, corrosive substances, and external pressures should be taken into account. For instance, if the project involves underground installation or exposure to corrosive chemicals, corrosion-resistant steel pipes may be necessary. 5. Budget: The budget available for the project is also an important factor to consider. The cost of steel pipes can vary depending on their material composition, dimensions, and additional features. It is crucial to strike a balance between the project requirements and the available budget to ensure cost-effectiveness without compromising the quality and performance of the pipes. In conclusion, when selecting steel pipes for a project, it is important to consider factors such as the material composition, pipe dimensions, intended application, environmental conditions, and budget. By carefully evaluating these factors, one can choose the most suitable steel pipes that meet the project requirements and ensure long-term performance and durability.

- Q: How are steel pipes used in the manufacturing of irrigation systems?

- Steel pipes are commonly used in the manufacturing of irrigation systems due to their durability, strength, and ability to withstand high water pressure. These pipes are used to transport water from the source to the farmland or fields, ensuring efficient and reliable irrigation. Additionally, steel pipes are corrosion-resistant, making them ideal for use in various environmental conditions.

Send your message to us

GR.B Carbon Seamless Steel Pipe With Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords