Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

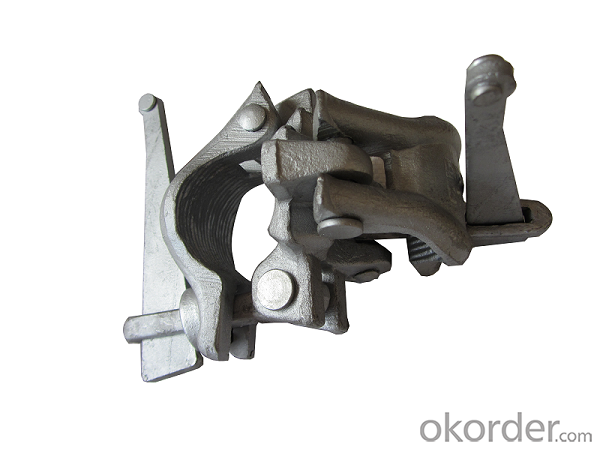

1. Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head Description

What is Scaffolding Coupler ?

Scaffolding Coupler is accessories of the scaffolding productions , it is usually made of Q235 steel material , The production technology can be forging or prssed , With the development of the construction , Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head has beome more and more popular.

Function of the Scaffold Coupler

Scaffolding Coupler Steel Galvanized Forged Coupler used to connect two scaffolding tubes at certain direction . The scaffolding coupler used to connect tubes and bulid hige woking towers .It can be used to 48.3mm tube or 48.3mm and 60mm tube Every size avaliable .

Advantage of Scaffold Coupler

Strong ability of resistance to deformation, for different manufacturing process, It can resistant deformation, ensure the product safety and effective use of repeated; Strong anti-sliding performance, joint area is large, fasteners and overcomes the cast iron steel tube a point or line defect of joint, remove of steel pipe slip hazard.

2.Main features of Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head

Reliable performance

Corrosion resistance

Durable finish standards

Strong anti-sliding performance

Manugacture

Good service

3.Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head images

4. Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head Specification

Raw Material: Q235

Size: 48.3mm

Weight:1.66kg

Certifies:, EN 74 and OSHA

Technology : Forging

Surface treatment: Electro galvanized, Hot DIP galvanized, or painted

Brand Name:FF

Useage: connecting the scaffolding pipe

OEM service offered

5.FAQ of Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head

Why you choose us ?

1)Highest quality -never use any equipment that is damaged or deteriorated in any way

2)Safety -inspect all equipment before using

3)Competitive price - factory suppler direct

4)We have strong engineering team that can give best solution for your project

5)Cutting -Edge product development

Consult your scaffolding supplier when in doubt-scaffolding is his business .Never take chances

Our firm belief that our customer's success are the only guarantee of our success .

Package ?

All the products package are suit for the sea transportation, steel and wooden plate is usual, if you need special package, Pls contact me for detail, we will meet your demands.

Delivery Time ?

For one 20GP container, the delivery time is about 15-25 days,

For 1-5 20GP containers, the delivery time is about 15-50 days.

For more than 5 containers, pls contact me ,our engineer will give you a delivery plan.

Product Quality

1) we can send you the samples for your checking our quality.

2) If you have time ,we welcome your coming to visit our factory.

- Q: I would like a scaffold piercing, but my parents aren't going to let me have two cartilage piercings at once. So, can they be done separately, as in weeks apart?

- Technically yes but it is better to have them done at the same time so the holes are aligned properly. It is better to get them done at the same time, as the second piercing will be less painful because you are all adrenalin-ed up! Probably cheaper too.

- Q: What are the chances of cracking the tile? What can I do to avoid cracking the tile?This will be 3 levels of scaffolding on 6 inch wheels.

- Put the wheels (locked) on 2 x 12 planks. This will distribute the weight.

- Q: Scaffolding installation and precautions?

- When the structural layer is attached to the wall, the wall column, the vertical horizontal rod and the transverse horizontal rod are set up immediately after the erection of the structure.5, closed with a step horizontal bar frame must turn around the hands all around the circle, with a right angle fastener and the inner and outer post fixed.6, the horizontal horizontal pole of the double row scaffold should not be greater than 100mm from the wall to the wall.7, when the scaffolding operation of the wall of the two steps, should take temporary stability measures, even after the wall pieces can be removed before the erection.

- Q: Also what 2 cell populations in the body that don't routinely undergo cell division

- The first one is vague. The answer could be the mitotic spindle. It might be kinetochore microtubules. It might be talking about the kinetchores on the chromosomes instead of the microtubules that attach to the kinetochores. It could possibly even be talking about the centromeres, though to me that seems less likely. Neurons in the adult brain (and mature muscle cells?) do not routinely undergo cell division.

- Q: I'm trying to understand a problem in my physics book. The problem is this:A person is pulling on a rope, that is connected to a pulley on the ceiling. The rope then goes to a box with a pulley on it, and then up to the ceiling where the rope is connected (to the ceiling).The rope and pulleys are massless and frictionless.The book lists three forces (tension forces) going up and one weight force pulling down.My question is, why isn't there another force pulling against the tension of the rope from the guy pulling the rope?

- well, the person is going to have to pull on the rope, and that will be another force that is not pictured in the book. if you think about it, when a rope is under tension, each end is getting pulled, like a tug of war, otherwise it just moves toward the other force. When the forces are balanced, the rope is in tension and does not move. The forces pictured in the book are tension provided by the weight. The person will have to add a tension force downward to compensate.

- Q: The classification of scaffolding and the relevant provisions of the provisions of the installation, please explain professional, thank you

- 1, the height of the super 24M drop steel scaffolding; 2, attached to the lifting of the scaffolding, including the overall lifting and chip upgrade; the 3, cantilevered scaffolding; the door scaffolding, scaffolding, the scaffolding, scaffolding, the scaffolding; the 5, hanging basket, scaffolding, scaffolding, and so on; 6;

- Q: Scaffolding installation process, construction preparation

- Construction preparation(1): steel pipe should be consistent with current national standard "carbon structural steel" (GB/T700) regulations Q235- grade steel; new steel pipe should be the product quality certificate; steel surface should be flat and smooth, no cracks, scarring, delamination, dislocation, bend, burr, indentation and scratch depth, pipe diameter deviation not more than -0.5mm, the wall thickness deviation not greater than -0.5mm, cutting slope deviation not greater than 1.7mm, the steel surface should be brushed with antirust paint; old steel corrosion depth not greater than 0.5mm, more than the prescribed steel shall not be used.(2): buckle made of malleable iron fasteners, the material should be consistent with current national standard "steel pipe scaffolding fasteners" (GB15831) regulations; old buckle inspect before use, shall not have cracks, deformation, bolt appear smooth silk must be replaced; new and old fastener must brush good antirust paint.(3) foot board: the use of 4m long wooden foot board; foot width of not less than 200mm, the thickness is not less than 50mm, both ends should be set with a diameter of 4mm galvanized steel hoop two; rotten feet can not be used.(4) safety net, paint.(5) after the inspection and acceptance of the above parts have been classified and piled up in a neat and orderly manner, no water can be accumulated.2, scaffolding erection and removal(1) scaffold erection

- Q: what are two burdens for each character? What action does each character indicate that she or he is indeed free from their burdens?

- Tell me what you know and I will elaborate. I had to read this book for a class and hated it, but I won't do your homework for you. I will help if you show you read it yourself and put in some effort we can see

- Q: Specific requirements, the civil code is what ah! Thank you very much, I am lack of this kind of information, I hope you can tell me which of the following

- The surface of the steel pipe shall be smooth and free of cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep scratches.The outer diameter of steel pipe 48mm allowable deviation is 0.5mm; the thickness of the wall 3.5mm allowable deviation of.0.5mm; steel pipe surface cutting oblique deviation 1.7mm;Dressing should be checked once a year. When the examination, should be in serious pipe corrosion in the selected three roots in each part of the serious corrosion of transverse sampling inspection, the outer surface of the steel pipe corrosion depth allowable deviation is less than 0.5mm, more than the provisions shall not be used.All new and old steel pipes must be painted with anti rust paint.

- Q: He pushes a can over the scaffold at 15 meters and it takes 3.25 seconds for it to land.I keep doing the problem over and over. the Correct answer is 20.5 m/s, however I keep arriving to the solution of 17 m/s. I solved it by doing Vf^2 = Vi^2 + 2adwhere the initial velocity is zero and the acceleration is -g. I made my coordinate system so that down is negative in which the distance will be negative. This however, did not give me the correct answer. Am I right or is the book right?

- The initial velocity is not zero since the scaffold is moving upward when the can gets pushed over. And final velocity, vf, does not represent the speed of the scaffold (if that is what you're trying to solve). y = (vo)(t) - (1/2)gt? 15 m = (vo)(3.25 s) - (1/2)(9.81 m/s?)(3.25 s)? vo = +20.5 m/s

Send your message to us

Scaffolding Coupler Steel Galvanized Forged Right Angle Coupler with Wedge Head

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords