Scaffolding Building Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Scarffolding Building Structure Pipe:

1) Standard: BS EN39 Loose steel tubes for tube and coupler scaffolds -- Technical delivery conditions

other size also can be manufactured, please contact us for detail information.

2) Surface Treatment: Galvanized , Oiled, Painted , Bare

3) End treatment: Beveled , Plain , Threaded

4) Test: Chemical Component Analysis, Mechanical Properties, Technical Properties, Exterior Size Inspection

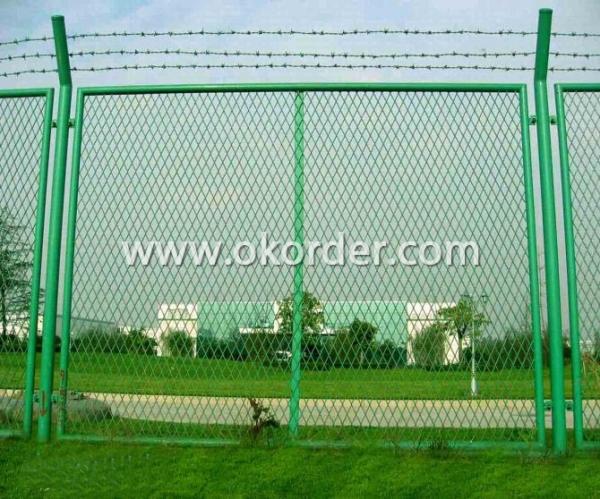

5)Application: Fence, Construction.

6)Certificate: SGS Inspection

7)Delivery Time: usually in 20--30 days

8) Payment Term: T/T , L/C

Application of Galvanized , Oiled, Painted , Bare Scaffolding Building Structure Pipe BS EN39, A500 A,B,C, D.

A53 A,B.S275, S355, C250, C350

2. Tecnical Data:

Chemical Composition of Raw Materials | Mechanical Property of Raw Materials | ||||||||||

Item | Chemical Composition % | Item | Mechanical Property | ||||||||

Steel | Steel No. | C | Mn | S | P | Si | Al | Steel | Yield point Mpa min | Tensile Strength Mpa | Elongation % min |

S235GT | 1.0106 | < 0.20 | < 1.40 | < 0.045 | < 0.040 | < 0.05 | > 0.020 | S235GT | 235 | 340--520 | 24 |

Other material: A500 A, B, C , D. A53 A, B. S275, S355, C250, C350 | |||||||||||

3. Standard Size for Reference

OD (mm) | WT(mm) | L (mm) | Tolerance (min) (mm) | Zinc Coating g/m2 |

48 -- 48.6 | 2--7 | 300 -- 6000 | WT +/- 0.2 , L - 0 -- + 3 | 280--400 |

application of scaffolding pipe (ERW welded pipe)

- Q: How to descaling galvanized steel pipe?

- Is red rust or white rust, red rust is the base material rust, white rust is Zinc Coating Rust

- Q: What are the different methods of pipe bending for steel pipes?

- There are several methods of pipe bending for steel pipes, each with its own advantages and limitations. 1. Manual Pipe Bending: This method involves using hand tools or a manual pipe bender to bend the steel pipe. It is suitable for small-scale projects or when only a few bends are required. However, it requires skill and precision to ensure accurate and consistent bends. 2. Rotary Draw Bending: This method utilizes a mandrel, clamp die, and a bending die to bend the pipe around a stationary bend die. The mandrel helps to maintain the shape and prevent wrinkling or collapsing of the pipe during the bending process. Rotary draw bending is commonly used for producing tight-radius bends with high accuracy and repeatability. 3. Induction Pipe Bending: In this method, an induction coil is used to heat a specific area of the steel pipe, making it more malleable for bending. Once the desired temperature is reached, the pipe is bent using hydraulic or mechanical force. Induction bending is suitable for large-diameter pipes or when multiple bends are required in a single pipe. 4. Roll Bending: Also known as pyramid rolling, this method involves passing the steel pipe through three adjustable rolls that gradually bend the pipe into the desired shape. Roll bending is suitable for producing large-radius bends and is commonly used in the construction of spiral staircases, handrails, and structural applications. 5. Hot Bending: This method involves heating the steel pipe to high temperatures, typically using a furnace, to facilitate bending. Hot bending allows for greater flexibility in shaping the pipe and is commonly used for large-diameter or thick-walled pipes. However, it requires specialized equipment and expertise to control the temperature and prevent distortion or damage to the pipe. It is important to consider factors such as the required bend radius, pipe diameter, wall thickness, and project specifications when selecting the appropriate method of pipe bending for steel pipes. Consulting with an experienced pipe bending professional or engineer can help determine the most suitable method for a specific application.

- Q: How are steel pipes used in the manufacturing of storage tanks?

- Steel pipes are commonly used in the manufacturing of storage tanks as they provide structural strength and durability. These pipes are used to create the framework or skeleton of the tank, providing support and stability to hold large volumes of liquid or gas. Additionally, steel pipes are often used for the inlet and outlet connections, as well as for internal piping systems that allow for the transportation of substances within the tank. Overall, steel pipes play a crucial role in ensuring the integrity and functionality of storage tanks in various industries.

- Q: What are the different types of pipe coatings used for corrosion protection?

- There are several types of pipe coatings used for corrosion protection, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings. Each type of coating offers specific advantages and is chosen based on factors such as the type of corrosive environment, the desired level of protection, and the budget constraints.

- Q: Can steel pipes be used for desalination plants?

- Yes, steel pipes can be used for desalination plants. Steel is often chosen for its high strength, durability, and resistance to corrosion, making it suitable for carrying and transporting the highly saline water used in desalination processes. Additionally, steel pipes can handle high pressure, ensuring efficient water flow throughout the plant.

- Q: Are steel pipes suitable for potable water applications?

- Yes, steel pipes are suitable for potable water applications. Steel pipes are commonly used for transporting water in various industries and municipal water systems. They are known for their durability, strength, and resistance to corrosion, making them a reliable choice for potable water systems. Steel pipes also have the advantage of being able to withstand high pressure and temperature conditions, making them suitable for both hot and cold water applications. Additionally, steel pipes can be easily welded, ensuring leak-free connections. However, it is important to note that the quality of the steel used and proper maintenance are crucial factors in ensuring the safety and suitability of steel pipes for potable water applications. Regular inspection and maintenance should be done to prevent corrosion and ensure the integrity of the pipes.

- Q: What are the main aspects of precision steel tubes?

- Precision tube is a kind of seamless steel tube with high precision and high brightness produced by cold drawing or cold rolling.

- Q: What are the common methods for cleaning the inner surface of steel pipes?

- There are several common methods for cleaning the inner surface of steel pipes. Some of the most widely used methods include: 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, scrapers, or abrasive pads to physically remove debris, rust, or scale from the inner surface of the steel pipe. This method is effective for removing loose or loosely adhered contaminants. 2. Chemical Cleaning: Chemical cleaning involves the use of acidic or alkaline solutions to dissolve or loosen stubborn deposits, rust, or scale on the inner surface of steel pipes. The solution is usually circulated through the pipe for a specific period of time, allowing the chemical to react and break down the contaminants. This method is often used when mechanical cleaning is not sufficient. 3. High-Pressure Water Jetting: In this method, high-pressure water is directed through a nozzle into the steel pipe, effectively removing debris, rust, or scale from the inner surface. The force of the water jet helps dislodge and flush out the contaminants. This method is particularly efficient for cleaning pipes with complex geometries or hard-to-reach areas. 4. Shot Blasting: Shot blasting involves the use of high-speed abrasive particles propelled against the inner surface of the steel pipe to remove rust, scale, or other contaminants. This method is commonly used for larger pipes or pipes with heavy deposits. It provides a thorough and uniform cleaning by removing the surface layer of the steel along with the contaminants. 5. Ultrasonic Cleaning: Ultrasonic cleaning uses high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the inner surface of the steel pipe, effectively loosening and removing contaminants. This method is particularly effective for cleaning small-diameter pipes or pipes with intricate details. It is important to note that the selection of the cleaning method depends on various factors such as the type and extent of contamination, pipe size and geometry, and the desired level of cleanliness. Additionally, proper safety measures should always be taken when performing any cleaning method to ensure the protection of workers and the integrity of the steel pipes.

- Q: How are steel pipes marked for identification?

- Steel pipes are marked for identification through a process called pipe marking. This involves applying labels or markers on the surface of the pipes to provide relevant information about their specifications and characteristics. The markings typically include details such as the pipe's size, grade, material composition, manufacturer's logo or name, and any other relevant codes or standards. These markings are crucial for identification and help ensure that the correct pipes are used for specific applications, as well as for maintenance and repair purposes. Additionally, the markings also aid in quality control and traceability, enabling easy identification and tracking of pipes throughout their lifecycle. Overall, proper identification of steel pipes through clear and durable marking systems is essential for maintaining safety, efficiency, and compliance in various industries where these pipes are utilized.

- Q: How are steel pipes used in the construction of biomass power plants?

- Steel pipes are used in the construction of biomass power plants for various purposes, including transporting and distributing steam, water, and other fluids throughout the facility. They are also used for the construction of boiler systems, as well as for conveying fuel and exhaust gases. In addition, steel pipes are essential for the structural integrity of the plant, providing support and durability in various applications.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1997 |

| Annual Output Value | Above Three Million To Five Million RMB |

| Main Markets | Main land |

| Company Certifications | ISO 9001:2010;API 5L; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 40% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Scaffolding Building Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords