Insulation Rubber Plastic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

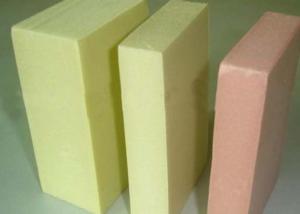

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to utilize black fiberglass tissue for the purpose of thermal insulation within construction projects?

- <p>Yes, black fiberglass tissue can be used for thermal insulation in buildings. It is a type of insulation material that is known for its ability to resist heat flow, thereby reducing heat transfer. Black fiberglass, or more commonly referred to as black fiber glass, is a variant of fiberglass insulation that has been treated with a black pigment to increase its resistance to ultraviolet light, which can be beneficial for applications where the insulation material is exposed to sunlight. This type of insulation is effective in maintaining indoor temperatures by reducing heat loss in the winter and heat gain in the summer, thus contributing to energy efficiency and comfort in buildings.</p>

- Q: As opposed to other roof structures, such as Mansard or Hipped roofs. If so, is it because there is a lesser distance between the internal heat source and the roof?

- For insulation, what is important is the material it is done and how it is positioned (different materials used on the same roof), and not it if flat or anything else.

- Q: This question asks for the cost of black fiberglass tissue.

- <p>The cost of black fiberglass tissue can vary significantly based on factors such as the quality, quantity, and location. As of my last update, prices for fiberglass tissue can range from a few dollars per square meter for lower quality to over $100 per square meter for high-quality materials. It's best to check with local suppliers or online marketplaces for the most current pricing as it can fluctuate due to market conditions and availability.</p>

- Q: Explain the differences between food wrap and aluminum foil facing in a few sentences.

- <p>Food wrap, also known as plastic wrap, is a thin, flexible plastic film used to cover and preserve food, keeping it fresh and protected from contaminants. It's typically clingy and transparent, allowing you to see the food inside. Aluminum foil facing, on the other hand, is a type of laminate that has a layer of aluminum foil bonded to a plastic film. This facing is used for various purposes, including increasing the barrier properties of the plastic, providing a shiny appearance, and enhancing the product's durability. It's often used in packaging to protect and preserve food items, but it's not as clingy or transparent as food wrap and is not meant for direct contact with food in the same way.</p>

- Q: Hello, this is quite an ordeal I've got. I am renting a cabin that has galvanized metal sheets as roofing. These are of course nailed into large wooden beans that run all acrooss.The owner and I made a deal, that deal is that I will put up insulation on the roof. However, she wants to put (i don't knw what they are called) big rectangular styrofam blocks (about 3x9 feet long). She wants me to cut them up to a width where they will feet in between the wooden beams and somehow secure them on. My idea of securing them is by nailing a plastic covering over them. but I am unsure about how to do the rest. How will i get the blocks to stay put if i cannot nail them? is there a better and CHEAP way to do it?As of now, if you look up you see the wooden beams and the tin metal roof. She wants it to be insulated and not visible.

- The foamboard can be installed in between the beams Do NOT use adhesives to fasten the foamboards or drywall. The adhesive will deteriorate over time and the foamboards and drywall will fall down. Many municipalities do not allow materials to be attached only by adhesives especially on walls and ceilings. Nail or screw 1 X 3 or 1 X 4 boards under the foamboard from beam to beam spaced about 16 inches apart. Screw drywall for fireproofing to the 1 X 3s or 4s and this will also hide the foam boards. Tape and seal the joints

- Q: EPS insulation board SPS insulation board what is the difference

- Ventilation ducts are generally metal pipes are also fiberglass or other materials of the pipeline, the pipes are hard material, the fan running when the skeleton refused to pull the agent off the biased floor vibration, if there is no soft connection, the vibration will be through the hard material ventilation Pipeline pass very far, the formation of noise pollution

- Q: Can black fiberglass tissue be utilized effectively for the purpose of window cleaning?

- <p>Yes, black fiberglass tissue can be used for cleaning windows. It is a durable and non-abrasive material that effectively removes dirt and grime without scratching the glass surface. The fine fibers can reach into small crevices and effectively clean the window. However, it's important to ensure that the fiberglass tissue is clean and free from any debris or particles that could potentially scratch the glass. Always test a small, inconspicuous area first to ensure it doesn't damage the window.</p>

- Q: The user is asking if they can use their old towels as a replacement for black fiberglass tissues.

- <p>While it might be tempting to repurpose old towels as a substitute for black fiberglass tissues, it's not advisable. Black fiberglass tissues are specifically designed for certain applications due to their unique properties, such as heat resistance and strength. Old towels, even if they are black, lack these specific characteristics and may not provide the same level of performance or safety. It's best to use materials as intended to ensure effectiveness and avoid potential issues.</p>

- Q: Is it permissible to use black fiberglass tissue in the construction or components of food processing equipment?

- <p>Black fiberglass tissue is not typically used in food processing equipment due to concerns about food safety and contamination. Fiberglass can potentially shed particles that could contaminate food products. Instead, food processing equipment usually employs materials that are food-grade and non-reactive, such as stainless steel, which is both durable and safe for contact with food. It's crucial to use materials approved for food contact to ensure the safety and quality of the food products.</p>

- Q: Is it possible to use black fiberglass tissue to clean oil stains?

- <p>Yes, black fiberglass tissue can be used for wiping oil stains. It is a non-conductive material that can effectively absorb and remove oil. However, it's important to use it with caution as the rough texture of fiberglass can potentially scratch surfaces. Additionally, it's recommended to wear protective gloves while using fiberglass tissue to avoid skin irritation. Always check the manufacturer's guidelines for the specific product to ensure it's suitable for the task at hand.</p>

Send your message to us

Insulation Rubber Plastic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords