Rubber Plastic Insulation for Air Conditioning

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

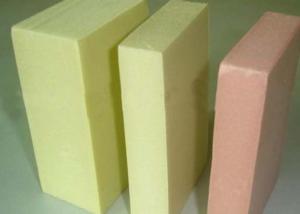

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it safe to use aluminum foil facing to wrap food for the purpose of freezing?

- <p>Yes, you can use aluminum foil facing to wrap food for freezing. Aluminum foil is a good conductor of heat and can help food freeze quickly, preserving its freshness. It also protects the food from freezer burn and helps maintain its moisture. However, ensure that the foil is food-grade and avoid using it in direct contact with acidic or high-sodium foods, as these can cause a reaction with the aluminum. For best results, wrap the food tightly and securely to prevent air exposure, which can lead to freezer burn.</p>

- Q: Will the embedded stove why use stainless steel corrugated hose connection?

- The construction of the scaffolding of this project is subject to the requirements of the relevant sections of the latest JGJ130-2011 "Safety Code for Construction Fastener Steel Scaffolding" To design and calculation, the preparation of special safety construction program, after the implementation of the approval. The preparation of the steel pipe should be selected first vertical and horizontal spacing and horizontal bar step, only these are determined in order to calculate the amount of steel pipe.

- Q: What are the eco-friendly alternatives to traditional plastic food wraps?

- <p>Yes, there are several environmentally friendly alternatives to traditional plastic food wraps. These include beeswax wraps, which are reusable and made from natural materials like cotton, beeswax, and jojoba oil. Another option is silicone food wraps, which are durable, reusable, and can withstand high temperatures. Additionally, there are compostable wraps made from plant-based materials like cornstarch and cellulose, which break down naturally in compost. Using reusable containers or aluminum foil can also reduce the need for single-use wraps. These alternatives help reduce plastic waste and are more sustainable for the environment.</p>

- Q: I have 4 pieces (about 50 sq ft) of odd shaped polystyrene foam insulation between 3&quot; and 4&quot; thick. it's leftover from installing a flat roof. creative ideas anyone?

- Use it as insulation in the basement. Place it under the floor along your rim joists above the foundation

- Q: What is the difference between a rigid pipe and a flexible pipe, what kind of pipe is rigid, what is flexible

- Tower crane is used to lift objects up and down the lifting of the object is not clear the length of the arm of the tower crane!

- Q: Is it safe to use aluminum foil facing for storing perishable foods like milk or yogurt?

- <p>Using aluminum foil facing for storing perishable foods like milk or yogurt is generally safe. Aluminum foil doesn't react with these foods and can help maintain freshness by providing a barrier against light and air. However, it's important to ensure that the foil is food-grade and that the container is properly sealed to prevent contamination. Always check the foil for any tears or punctures that could compromise the integrity of the seal. Additionally, avoid using aluminum foil in direct contact with acidic foods as it may cause a reaction over time.</p>

- Q: This question asks for methods to properly store and transport black fiberglass tissue, a material that requires careful handling to maintain its integrity.

- <p>To effectively store and transport black fiberglass tissue, ensure the following: Store the tissue in a cool, dry place away from direct sunlight to prevent degradation. Use airtight containers or wrappings to protect it from moisture and dust. When transporting, use a clean, dry vehicle and avoid stacking heavy items on top to prevent compression damage. Secure the material to prevent shifting during transit. Handle the tissue with clean, dry hands or gloves to avoid contamination. Always follow the manufacturer's guidelines for specific storage and transport recommendations.</p>

- Q: What distinguishes black fiberglass from other types of glass fiber in terms of properties and applications?

- <p>Black fiberglass is a type of glass fiber that has been treated with a black pigment or dye, which gives it a distinct appearance and specific properties. Unlike other types of glass fibers which can be clear or have other colors, black fiberglass is primarily used for aesthetic purposes or to absorb light, reducing glare and reflections. It is often used in applications where a dark, non-reflective surface is desired, such as in some types of automotive components, exterior building materials, or in certain industrial settings. Other types of glass fibers may be used for their strength, insulation properties, or electrical non-conductivity, and are not necessarily colored. The choice between black fiberglass and other types of glass fibers depends on the specific requirements of the application in terms of appearance, performance, and functionality.</p>

- Q: Can fiberglass facing be painted or customized?

- Certainly! Fiberglass facing has the capability to be painted or personalized. Fiberglass, known for its versatility, can be easily painted with a variety of paint types, including acrylic or oil-based options. Prior to painting, it is crucial to adequately prepare the surface by thoroughly cleaning it and eliminating any dirt or debris. Additionally, it is advisable to utilize a primer to enhance adhesion and guarantee a polished outcome. Once the primer has dried, you can proceed to apply the desired paint color or personalize the fiberglass facing through the use of stencils, decals, or other decorative techniques. Nevertheless, if the fiberglass facing is going to be exposed to harsh weather conditions, it is vital to utilize paint and materials suitable for outdoor use. By undertaking the appropriate preparations and utilizing the right paint, fiberglass facing can be painted or personalized to satisfy your specific aesthetic preferences or design requirements.

- Q: This question asks about the environmental effects of utilizing black fiberglass tissue.

- <p>The use of black fiberglass tissue can have several environmental impacts. It is often used in construction and insulation, which can reduce energy consumption and lower greenhouse gas emissions. However, the production process can be energy-intensive and may release pollutants. Additionally, black fiberglass tissue can contribute to urban heat island effect due to its dark color, which absorbs more heat. Proper disposal is crucial as improper disposal can lead to environmental contamination. Overall, while it has benefits in insulation, the environmental impact must be managed through sustainable production and disposal practices.</p>

Send your message to us

Rubber Plastic Insulation for Air Conditioning

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords