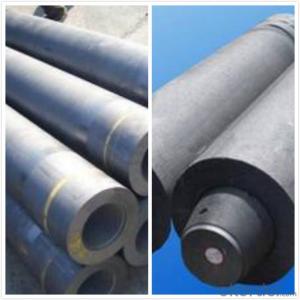

Low Specific Resistance RP, HP, and UHP Type Graphite Electrode for Steel Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TECHNICAL PROPERTIES OF GRAPHITE ELECTRODE

1.Physical and chemical index

Item | Unit | RP | HP | UHP | ||||

250-400 | 450-800 | 300-400 | 450-700 | 300-400 | 450-700 | |||

Electric Resistivity | Electrode | μΩ.m | 7.5-8.6 | 7.5-8.8 | 5.5-6.8 | 5.5-7.0 | 4.6-6.0 | 4.8-6.2 |

Nipple | 4.5-5.5 | 4.0-5.0 | 3.5-4.5 | |||||

Bending Strength | Electrode | MPa | ≥8.0 | ≥11.0 | ≥11.0 | |||

Nipple | ≥15.0 | ≥16.0 | ≥18.0 | |||||

Elastic Modulus | Electrode | GPa | ≤9.0 | ≤11.0 | ≤13.0 | |||

Nipple | ≤13.0 | ≤14.0 | ≤15.0 | |||||

Bulk Density | Electrode | g/cm3 | 1.55-1.65 | 1.63-1.73 | 1.65-1.75 | |||

Nipple | 1.70-1.75 | 1.73-1.80 | 1.75-1.82 | |||||

Ash | Electrode | % | ≤0.3 | |||||

Nipple | ||||||||

CTE (100-600)℃ | Electrode | 10-6/℃ | 2.00-2.50 | 1.80-2.00 | 1.30-1.50 | |||

Nipple | 1.50-1.80 | 1.50-1.80 | 1.20-1.40 | |||||

2.Recommended current carrying capacity

Nominal Diameter (mm) | RP | HP | UHP | ||||

Current Carrying Capacity | Current Density | Current Carrying Capacity | Current Density | Current Carrying Capacity | Current Density | ||

in | mm | A | A/cm2 | A | A/cm2 | A | A/cm2 |

12 | 300 | 1000-13000 | 14-18 | 13000-174000 | 17-24 | 15000-22000 | 20-30 |

14 | 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

16 | 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

18 | 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

20 | 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

22 | 550 | 32000-40000 | 13-16 | 35000-55000 | 14-22 | 42000-64000 | 17-26 |

24 | 600 | 35000-41000 | 13-15 | 41000-61000 | 14-21 | 50000-73000 | 17-25 |

28 | 700 | 39000-48000 | 10-12 | 55000-82000 | 14-21 | 67000-99000 | 17-25 |

32 | 800 | 43000-54000 | 8-10 | / | / | / | / |

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: The future of graphene

- Sensor domain. Graphene due to its unique two-dimensional structure is widely used in sensor, has the advantages of small size, large surface area, high sensitivity, fast response time, fast and easy electron transfer protein immobilization and maintained its activity and other characteristics, can improve the performance of sensor. Mainly used in the production of gas, biological molecules, enzymes and DNA electrochemical sensors. Singapore Nanyang Technology University developed a graphene light sensor sensitivity is 1000 times the ordinary sensor; the Rensselaer Polytechnic Institute developed performance than the existing commercial gas sensor cheap graphene sponge sensor.

- Q: What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- Because in the process of electrolysis of water in cathode electron generated hydroxyl, the alkaline solution increased. But with the hydroxyl reaction of sodium carbonate and sodium bicarbonate, carbonate and calcium ions exist at the same time, must produce the precipitation of calcium carbonate, the ion in the solution is reduced, thereby conductive resistance increases. Thus weakened over time current cannot be raised

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- But because the silicon carbide is too hard, it is difficult to machining, good workability, such as non special requirements, using graphite instead of silicon carbide, instead of the effect is not good, but can use a silicon carbide, easy processing, small life than silicon carbide.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: What's the use of carbon?

- High power graphite electrode. Allows the use of current density of 18 ~ 25A/ cm 2 graphite electrode, mainly used in steel-making high power arc furnace

- Q: What do carbon products include?

- Carbon products can be divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, carbon fiber, special graphite, graphite heat exchanger and so on according to the use of products. Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density.

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- The energization is the electrolysis of CuCl2 solutions, i.e., redox reactions. So you can't mix ionization and electrolysis.

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The problem is this. I have done the test of electrolytic copper sulfate, and the anode produced the same phenomenon. Finally, the chemistry teacher told me that it was because the graphite was broken in the process of electrolysis

- Q: How do graphitized electrodes differentiate between high power and low power?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- The utilization ratio of graphite energy can reach more than 95%. Many kinds of antioxidant paint, it is recommended to directly find their technicians, you can give professional advice, according to the actual situation, the reasonable use of high-temperature oxidation resistant paint.

Send your message to us

Low Specific Resistance RP, HP, and UHP Type Graphite Electrode for Steel Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords