UHP Ultra High Power Graphite Electrodes for Eaf in Steel Industries

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin:

Shandong, China

Brand Name:

haihan

Model Number:

RP, HP, UHP

Type:

Electrode Block

Application:

furnace(EAF, LF)

Length:

1800, 2100, 2400, 2700mm

Grade:

RP (Regular Power)

Resistance (μΩ.m):

4.0-8.8

Apparent Density (g/cm³ ):

1.55 - 1.82

Thermal Expansion:

1.10-2.6

Flexural Strength (N/㎡):

≥8Mpa

Raw Material:

Needle Petroleum Coke & Fine Calcined Petroleum Coke

Nipple:

3TPI,4TPI or 4TP Long

Ash:

≤0.3

Supply Ability

20000 Ton/Tons per Year China Manufacturer High Carbon UHP/HP/RP Graphite Electrode

Packaging & Delivery

Packaging Details: wooden case/pallets with steel strips or as per our clients' request

Port: Tianjin

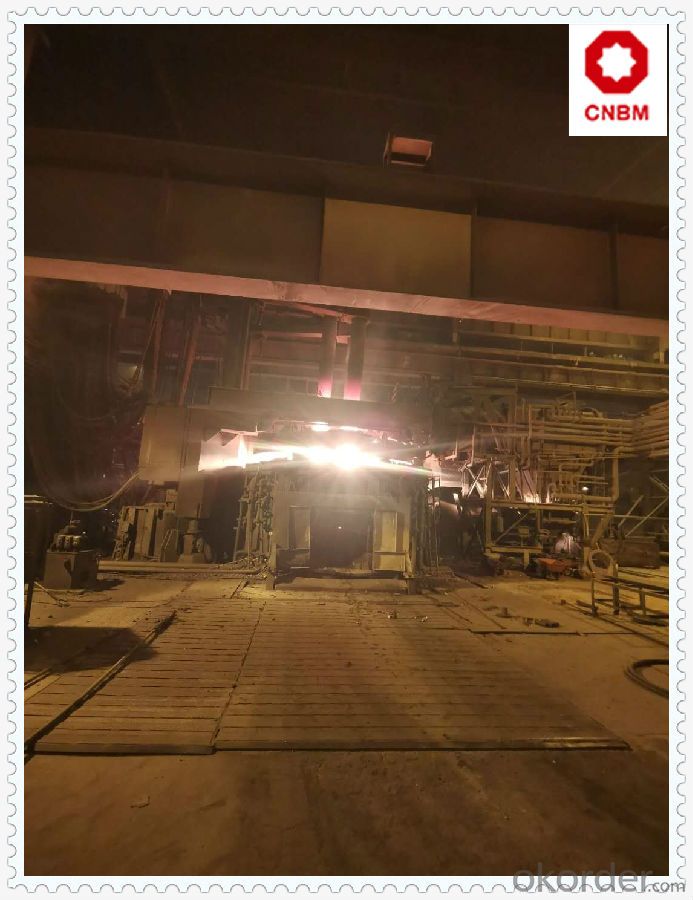

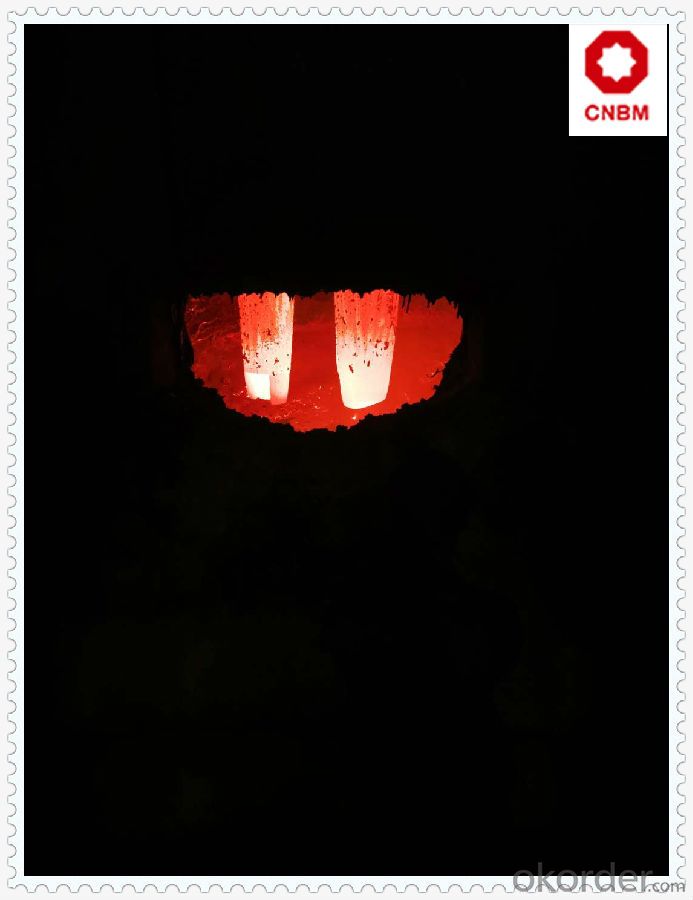

Picture Example:

Lead Time :

Quantity(Tons) 1 - 20 >20 Est. Time(days) 15 To be negotiated

Product Description

Items | 300~400 | 450~500 | 550~600 | 700 |

Specific Resistance | 6.2 | 6.3 | 6.3 | 6.3 |

5 | 5 | 4.5 | 4.5 | |

Bending Strength | 10.5 | 10.5 | 11 | 11 |

18 | 18 | 20 | 20 | |

Young's Modulus | 14 | 14 | 14 | 14 |

18 | 18 | 22 | 22 | |

Bulk Density | 1.66 | 1.66 | 1.66 | 1.66 |

1.73 | 1.73 | 1.75 | 1.78 | |

CTE | 1.5 | 1.5 | 1.4 | 1.4 |

1.4 | 1.4 | 1.2 | 1.2 | |

Ash Content | 0.3 | 0.3 | 0.5 | 0.5 |

Application

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: Why use platinum ferroalloy instead of iron as electrode?

- General industrial grade silicon dioxide, because the preparation technology is different, can be divided into two types, one is dry, sintered (Fume Type), a wet precipitation type (Precipitated Type), and two of the surface area, the surface with hydroxyl (-OH) are the same, in general, the former the latter is more, less, the two surface has the tendency of hydrophilic, as for lipophilic polymer, such as paint, rubber... Etc.,... If the silica surface pre rendered hydrophobic, has a good effect.

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- But because the silicon carbide is too hard, it is difficult to machining, good workability, such as non special requirements, using graphite instead of silicon carbide, instead of the effect is not good, but can use a silicon carbide, easy processing, small life than silicon carbide.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- Indeed, the original battery electrode potential using two different electrodes, produce potential difference, so that the electron flow generated current. Graphite is used as an electrode because of its excellent electrical conductivity and stability

- Q: National standard for graphite electrodes

- The national standard normal power graphite electrode graphite electrode: the standard name standard classification number Q51 Standard No. YB/T 4088-2000 for YB/T 4088-2000 YB/T 4088-1992 2000/12/1, instead of the execution time of 0:00:00 release time 2000/7/26 0:00:00 adoption situation

- Q: Classification of graphite electrodes

- A graphite electrode coated with an antioxidant protective layer (graphite electrode, antioxidant). The utility model has the advantages of forming a protective layer capable of conducting electricity and resisting oxidation at high temperature, reducing electrode consumption (19%~50%) during the steelmaking process of the poly carbon graphite electrode, prolonging the service life of the electrode (22%~60%), and reducing the electric energy consumption of the electrode. The popularization and use of this technology can bring about such economic and social effects:The unit consumption of graphite electrode is less, and the production cost is reduced.The power consumption of the graphite electrode is less, the energy consumption per unit of steelmaking is saved, the production cost is saved, and the energy saving is saved.Because the number of graphite electrodes is changed less, the labor quantity and danger coefficient of operators are reduced, and the production efficiency is improved.Graphite electrode is a kind of low consumption and low pollution product. It has a very important social significance in today's energy saving, emission reduction and environmental protection.

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Because the metal activity order form sodium potassium calcium magnesium aluminum, zinc and tin lead (hydrogen), mercury copper silver platinum, iron in the front row because of water water hydrogen, ionized hydrogen ions by iron replacement

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: Carbon graphite electrode and what is the difference?

- The material is composed of carbon carbon, but without graphite, after molding sintering temperature is only more than 1000 degrees, no graphitization.

- Q: What is the difference between SGL graphite electrode and graphite electrode in general?

- Pure graphite is a kind of high-purity graphite. The processing technology of fine graphite and high purity graphite is basically the same, that is, the purity of graphite is different, the purity is higher, and the particle size is basically the same

Send your message to us

UHP Ultra High Power Graphite Electrodes for Eaf in Steel Industries

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords