Round Ductile/ Cast Iron D400 Manhole Cover with Frame (DN600)

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects.

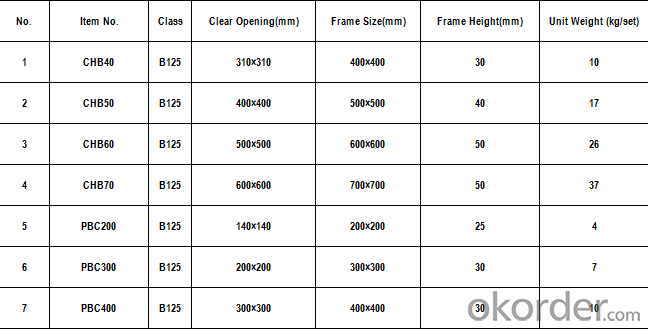

Specifications:

About Our Company:

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

Feature:

1)Product information

Surface is smooth , free from sand holes, blow holes, distortion or any other defects.

2)Material Ductile Iron GGG500 / Grey Iron GG20.

3) Designs As per customers' drawings or samples.

4)Process Green sand with hand molding.

5) Coating Black Bitumen Coated, Without coating or Coating as per customers' requirement.

6)Packing wooden pallet with plastic layer or according to customers' request

We are an ISO9001:2000 certified enterprise in China, specializing in manufacturing various kinds of of ductile iron grating manhole covers .

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

Pictures:

Packaging & Shipping:

1.Packaging: Details Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 30-45 days.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Radial drilling machine can achieve boring, reaming function, but as much as you want, according to your requirements and material to determine!

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from scopeShanghai Zhejiang forest auto parts experts pointed out that the forging process can eliminate cast loose, metal welding holes, so an important part of high load working conditions, severe machinery, in addition to relatively simple shapes can be rolled plates, profiles or welded parts, the forging process. Because of its low cost and good economy, casting parts processing is widely applied and belongs to the basic process of modern machine building industry.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q: What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

Send your message to us

Round Ductile/ Cast Iron D400 Manhole Cover with Frame (DN600)

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords