Rolling Grinding Ball with High Hardness Low Breakage Rate for Cement Plant and Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

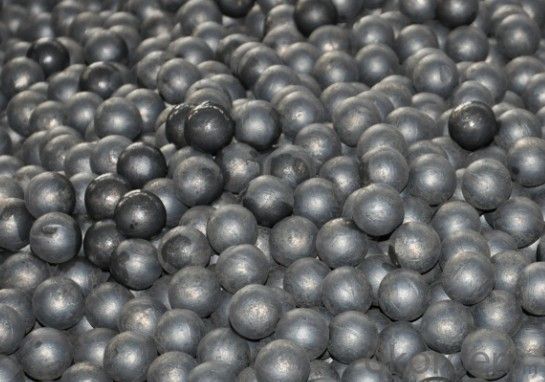

Features and Advantages of Rolling Grinding Ball with High Hardness Low

Breakage Rate for Cement Plant and Mineral Processing:

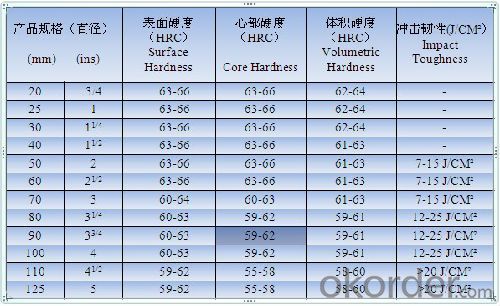

1) High hardness: It has high hardness: surface hardness can reach 55-67 HRC, volume hardness 56-64 HRC

2) High Impact toughness: impact toughness is more than 15 J / cm2.

3) Low Broken rate: peel fragmentation resistance property of over 20000 times. The actual breakage rate is less than 1% and close to 0.

4) Size: Our products range from 20mm to 150mm, 1 inch to 6 inch, and we can also offer all size of products according to clients’ demand.

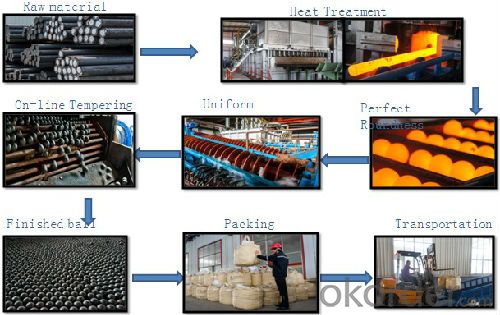

Production Procedure of Rolling Grinding Ball with High Hardness Low

Breakage Rate for Cement Plant and Mineral Processing:

Technical Parameters of Features and Advantages of Rolling Grinding Ball

with High Hardness Low Breakage Rate for Cement Plant and Mineral

Processing:

Complete Test System of Features and Advantages of Rolling Grinding Ball

with High Hardness Low Breakage Rate for Cement Plant and Mineral

Processing:

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Aluminum alloy die-casting parts or casting box and other parts of the threaded hole, in the case of processing conditions, it is best to use wire tapping or machine tool processing! Direct casting is not advocated.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Rolling Grinding Ball with High Hardness Low Breakage Rate for Cement Plant and Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches