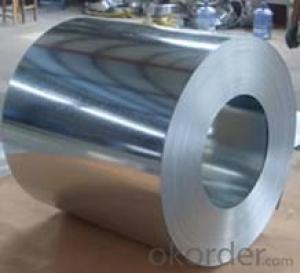

Rolled Coil Technique and Galvanized Surface Treatment Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,BS,DIN,GB,JIS | Grade: | TDX51D+Z | Thickness: | 0.3-0.7mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | Huaxi | Model Number: | TDX51D+Z |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Construction Applied | Width: | 914-1250mm | Length: | Steel Coil |

| Approved Certificate: | CE & SGS | HS Code: | 72107000 | Available Coating Colors: | Off White & Sea Blue & Others |

| Inner Diameter: | 508-610mm | Available Dipped Layers: | 50-150G/M2 | Base Metal: | DX51D+Z |

| Description: | Prepainted Galvanized Steel Coil |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy packing for international delivery |

| Delivery Detail: | According to the exact quantity of your order |

Cold Rolled Technique and Galvanized Surface Treatment Prepainted Galvanized Steel Coil

Brief Introduction

1. Prepainted Galvanized Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metal for Prepainted Galvanized Steel Coil is HDGI Steel. The finish coats of Prepainted Galvanized Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Galvanized Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Galvanized Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they are rolled into sheets, which are then cut and welded to create the walls, roof, and floor of the container. The high strength and durability of steel coils ensure that the shipping containers can withstand the rigors of transportation, protecting the goods inside.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the common methods of forming steel coils?

- There are several common methods for forming steel coils, each with its own unique advantages and applications. The most common method is known as hot rolling. This involves heating a large steel slab to a high temperature and passing it through a series of rollers to reduce its thickness. The steel is then coiled into a large, continuous roll. Hot rolling is typically used for producing steel coils with a consistent thickness and a smooth surface finish. It is commonly used in industries such as automotive, construction, and manufacturing. Another method is cold rolling, which is similar to hot rolling but is performed at room temperature. Cold rolling involves passing the steel through a set of rollers to further reduce its thickness and improve its surface finish. This process is often used to produce steel coils with precise dimensions and excellent mechanical properties. Cold-rolled steel coils are commonly used in applications that require high strength, such as in the production of appliances, electrical components, and structural components. A third method is known as galvanizing. This involves coating the steel coil with a layer of zinc to protect it from corrosion. The steel coil is first cleaned and then immersed in a bath of molten zinc. The zinc adheres to the surface of the steel, forming a protective layer. Galvanized steel coils are widely used in outdoor applications, such as roofing, fencing, and automotive parts, due to their excellent corrosion resistance. Lastly, there is the electro-galvanizing method. This process involves applying a thin layer of zinc to the surface of the steel coil through an electroplating process. The steel coil is immersed in an electrolyte solution and an electric current is passed through it, causing the zinc to deposit onto the surface of the steel. Electro-galvanized steel coils are commonly used in industries that require a smooth and aesthetically pleasing finish, such as in the production of appliances, automotive parts, and decorative items. Overall, these common methods of forming steel coils provide a wide range of options for different applications and requirements. Whether it is hot rolling, cold rolling, galvanizing, or electro-galvanizing, each method offers unique benefits in terms of strength, durability, surface finish, and corrosion resistance.

- Q: What are steel coils used for?

- Steel coils are used for a variety of applications, including manufacturing automobiles, construction materials, appliances, and machinery. They are also used in the production of pipes, electrical appliances, and packaging materials.

- Q: What are the different types of steel coil packaging materials?

- Some common types of steel coil packaging materials include wooden crates, steel frames, plastic strapping, stretch wrap, and steel bands.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- Actually-good grades of stainless is superior to high carbon steels which has been proven by countless tests. Aus8 is a japanese steel from what I know, so I'm not sure what the letter and number designation means. From what I know, Aus8 has similar properties to 440B though with a carbon content of around ~.74%. This is lower content then most other blade steels meaning it has lower edge retention. The stainless steels I'd consider to be best are: Ats-34: Less corrosion resistant then 440c, but is tougher then 440c and still holds a edge quite well 440c: Probably the best all around steel on the market for its price. Highest corrosion resistance and very good edge retention. I wouldn't recommend it on choppers though, a tougher steel like the one mentioned above would probably be better for that. A/B/C indicates the carbon content going from least to greatest. 4xx indicates that its a chrome martensitic steel. 40 indicates that its a high carbon grade compared to (4)20 which has less then .5 percent. CpmS30v: Slightly lower corrosion resistance then 440c due to it not taking a mirror finish, but very high edge retention and improved toughness. Cpm indicates that it's made by compressed particle metallurgy while the v indicates that its a vanadium alloy. I'm not sure what the S30 indicates.

- Q: What are the commonly used molds steel?

- Usually a hot working grade ( H series ) tool steel is used in die cast mold detail tooling. We typically use H-13 for our applications but have substituted with D-2 on occasion.

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings by enhancing insulation and reducing heat transfer. These coils are often used in heating, ventilation, and air conditioning (HVAC) systems to efficiently regulate temperature. The coils help transfer heat effectively, allowing for better control over indoor climate and reducing the energy required for heating or cooling. Additionally, steel coils are durable and require less maintenance, making them a cost-effective solution for long-term energy efficiency in buildings.

- Q: Where can I find a great deal online for Danesco Stainless Steel Egg Poacher

- looks like Target is going to be your best bet for about $35

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as they serve as the primary material for manufacturing various components such as the outer body, frame, and internal structures. These coils are formed into different shapes and sizes, allowing for the creation of durable and robust appliances. The steel coils provide strength, stability, and resistance to wear and tear, ensuring the longevity and reliability of the appliances.

Send your message to us

Rolled Coil Technique and Galvanized Surface Treatment Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords