Mirafi 500x Road Construction Short Geotextile Fabric with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Filament Spunbond Nonwoven Geotextile Description:

Made from virgin PET(polyester)chips,the continuous filament was extruded from

PET chip by machine directly by spunbond process,and then punch together to

get the stable 3D with higher strength fabric.So it has high strength, good creep

property excellent and erosion resistance,aging-resistance and heat resistance.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

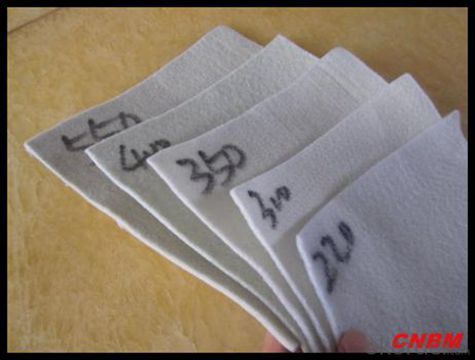

A: Yes, please check the pictures:

- Q: How do geotextiles aid in the reduction of pore water pressure?

- Geotextiles aid in the reduction of pore water pressure by providing a barrier that allows water to flow through while preventing the migration of fine particles. This allows for efficient drainage, preventing the build-up of excess pore water pressure within the soil or ground, ultimately reducing the risk of soil liquefaction or instability.

- Q: How do geotextiles help with stabilization of railway tracks?

- Geotextiles play a crucial role in stabilizing railway tracks by providing reinforcement and separation between different layers of the track structure. They prevent the mixing of materials, such as subgrade soil and ballast, while also reducing the lateral movement of the ballast. Geotextiles enhance the overall stability and load-bearing capacity of the track, reducing maintenance needs and extending its lifespan.

- Q: What are the advantages of using geotextiles in stormwater management?

- Geotextiles offer several advantages in stormwater management, including improved filtration and sediment retention, increased soil stabilization, and enhanced water infiltration rates. They help to reduce erosion and prevent sediment from entering water bodies, thus improving water quality. Geotextiles also provide support to vegetation and promote vegetative growth, contributing to the overall sustainability and effectiveness of stormwater management systems.

- Q: Can geotextiles be used in geosynthetic clay liners?

- Yes, geotextiles can be used in geosynthetic clay liners. Geotextiles are often used as a separation layer between the clay liner and the adjacent soil or as a protective barrier to prevent punctures or damage to the clay liner.

- Q: How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier, preventing sediment from washing away and polluting nearby water bodies. They retain soil particles while allowing water to pass through, thus reducing erosion and maintaining the stability of the construction site.

- Q: I only know how many grams per gram of geotextile, but do not know what the meaning of this TS30? More

- Product specifications: equivalent to weight 126g / m2

- Q: Garage roof covered with non-woven or geotextile cloth

- Geotextile also known as non-woven fabrics, with 200 to 300 grams of short wire geotextile can be

- Q: Composite geotextile per square meter of labor costs how much money 'sewage treatment pool' ground plane 'square meters. More

- Hello, the labor costs are calculated by the day, geotextile composite film to see what you need specifications, according to per square meter, the weight is not the same, the price is not the same

- Q: How do geotextiles contribute to soil stabilization in mining areas?

- Geotextiles contribute to soil stabilization in mining areas by providing a strong and durable reinforcement layer. They help prevent soil erosion, control sediment runoff, and improve the stability of slopes and embankments. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Additionally, they promote better drainage, allowing water to flow through the soil while retaining its structural integrity. Overall, geotextiles play a crucial role in maintaining the stability and safety of mining areas by enhancing the resilience of the soil.

- Q: How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects by providing several benefits. Firstly, they act as a barrier against soil erosion, reducing the need for costly erosion control measures. Secondly, geotextiles can improve soil stability and increase the load-bearing capacity of weak soils, eliminating the need for expensive soil stabilization techniques. Additionally, by acting as a separation layer, geotextiles prevent the mixing of different types of soils, reducing the amount of expensive fill material required. Lastly, geotextiles can prolong the lifespan of infrastructure by preventing the intrusion of fine particles and reducing the likelihood of soil settlement, saving on future maintenance and repair costs.

Send your message to us

Mirafi 500x Road Construction Short Geotextile Fabric with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords