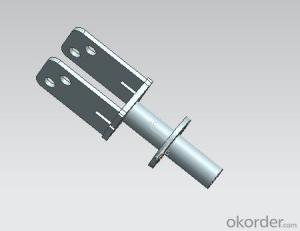

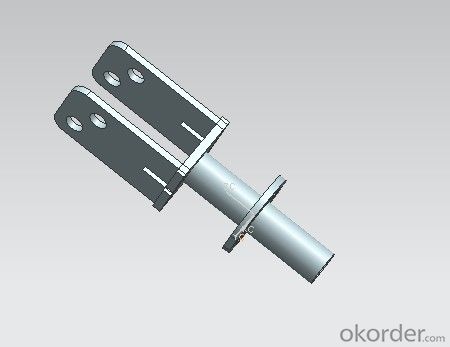

Ringlock System U Head

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

48.3 diameter x 3.2 thick high grade steel standard with arosette at 500mm intervals

Up to 8 connectons made at one level

Narrow opening in rosette position the ledgers at right angles

Wide opening in rosette allows alignment of ledgers and diagonal braces at the required angle

Connected by sliding wedge head forming part of the ledger over the rosette and inserting wedge into opening

our company is a professional scaffold & couplers manufacturer with year’s experience. We work for the based items(Stamping, fabrication and machining) and get the best price for some other parts from our 200 qualified supplier, these allow us have been providing to our valued customers from overseas(U.S., U.K, Australia, Canada, Germany, France) the following benefits and advantages:

Competitive pricing with good quality.

Turn-key solution to procurement of different types of components.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. Rental fees do not want the same

Send your message to us

Ringlock System U Head

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches