Ringlock Ledger End Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

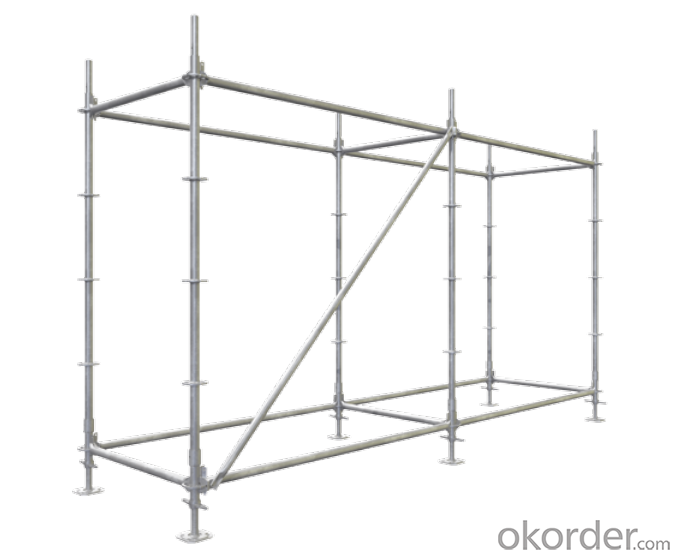

Ringlock Scaffolding

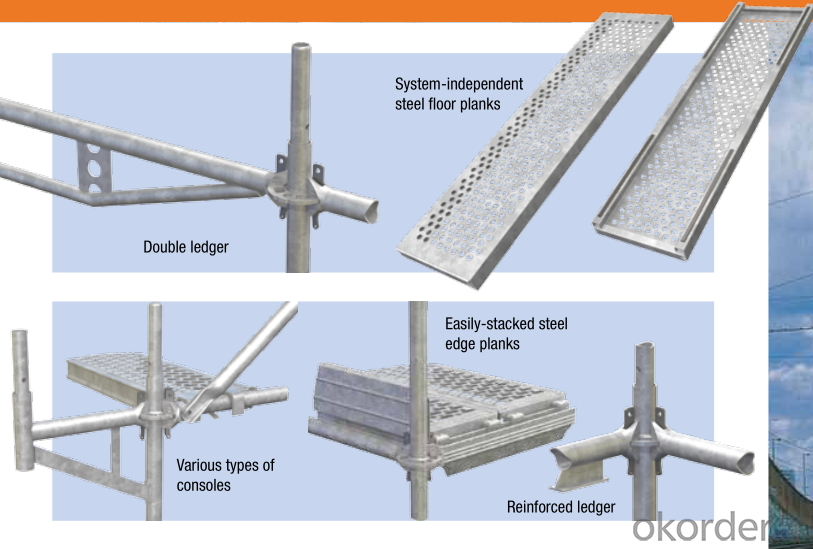

Ring Lock system is the latest item up to now. It’s mainly used in ship building, ship repairing, stage building etc.It’s stable, easy-assemble, easy working, safe-using and with big bearing capacity.

Main Features of the Ringlock Scaffolding

Place of Origin | Beijing, China (Mainland) |

Product Name: | Ringlock Scaffolding |

Custom Code | 7308400000 |

Color | Silver, golden |

Surface treatment | Painted,Hot-Dip,Galvanized,Electro Galvanized, Powder Coating |

Material | Q235,Q345.etc |

Package | Customized Package |

Payment Terms | T/T,L/C |

Delivery Detail | 15-25 Days |

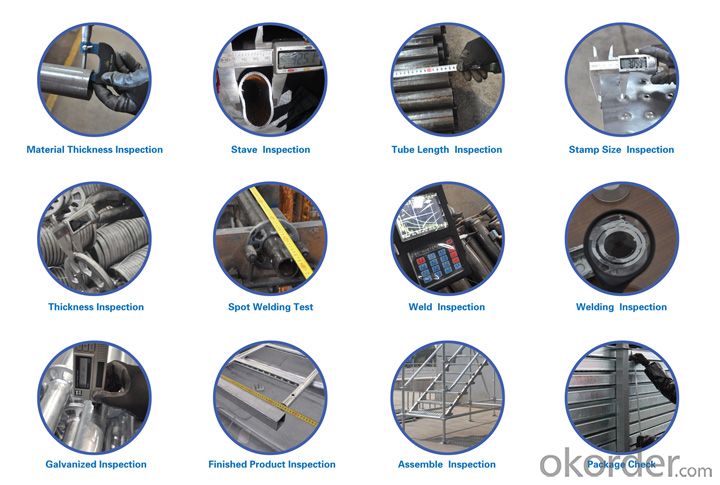

Quality Control | IS09001 Certification, Quality Test |

Standard | 48.3*3.25*4000mm |

Ledger | 48.3*3.25*3072mm |

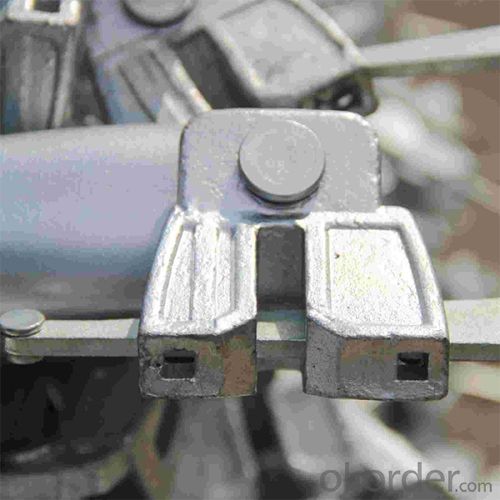

Ledger End | 1.2kg |

Advantages

1)To be erected easily and quickly

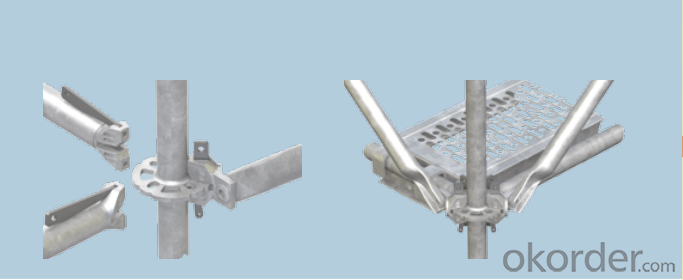

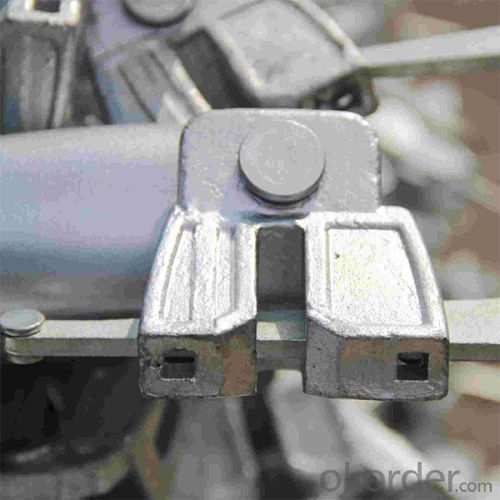

2)Installed to different angels with rosettes of

two different hole being positioned there

3)Ringlock scaffolding provides complete flexibility to lock in any angel.

4)Diagonal braces are to be tailored in

accordance with the lengths of vertical and horizontal tubes

Product Show

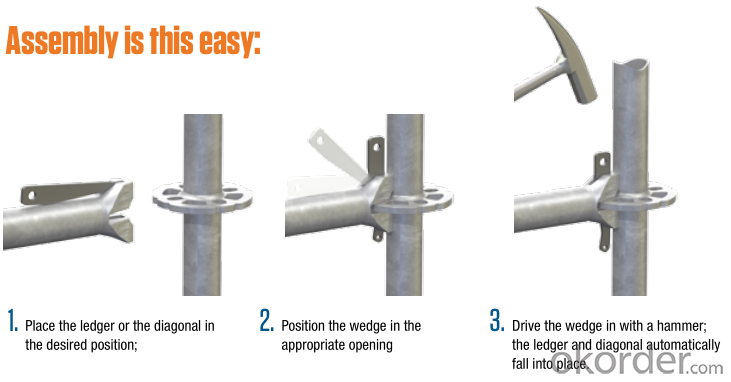

The modular RINGSCAFF system is characterised by the standardised, fast and simple assembly outlined above.

These procedures are continually repeated in the assembly of the scaffold.

In this way, as many as four ledgers and four diagonals can be attached to one ring! This creates a connection point which can bear very heavy loads.

Specification of Ringlock Scaffolding

The Standards(Verticals) | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

3000 | 3/3.25 | 48 | HDG/Painted | |

2500 | 3/3.25 | 48 | HDG/Painted | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1500 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

500 | 3/3.25 | 48 | HDG/Painted | |

The Ledgers(Horizontals) | ||||

Effective Length(mm) | Tube Thickness(mm) | Tube Diameter | Surface Treatment | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1770 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

The Diagonal Brace | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

2411 | 3 | 48 | HDG/Painted | |

2244 | 3 | 48 | HDG/Painted | |

The bracket | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

730 | 3 | 48 | HDG/Painted | |

Plank | ||||

Effective Length(mm) | Width(mm) | Height(mm) | Surface Treatme | |

2050 | 480 | 45 | HDG | |

1820 | 480 | 45 | HDG | |

3000 | 240 | 45 | HDG | |

2000 | 240 | 45 | HDG | |

1000 | 240 | 45 | HDG | |

Hollow Head Jack And Jack Base | ||||

Length(mm) | Tube Diameter(mm) | Size of Plate(mm) | Surface Treatment | |

600 | 38 | 150*120*50*4 | HDG | |

600 | 38 | 150*150*4 | HDG | |

- Q: Okay I have some questions:-When I get it done can I have- 2 labret retainers put in to hide them from my school?-If I can, how discreet are the retainers?-How long to heal? (Even though the piercer will tell me)-Have you got a picture of a scaffolding piercing with retainers? May I see it (:-And a basic clear cleaning regime?Thankyous (: x

- You could but it be best for a bar to be honest. Well retainers are clear and depending on your skin complexion it may be difficult or easy to detect. Industrials hurt I'm not going to lie. It look forever for mine to finally heal enough to wear i can lay on it. Your ear will throb and it will hurt like hell to touch it. The pain goes on for a couple of months. Sorry I have no pictures. For cleaning- Sea salt and warm water.

- Q: I got mine done this morning, and like the dumba** I am, I got it on the side that I sleep on. A friend of mine said she slept on hers the first night and didn't hurt and it was fine, but I don't believe that to be true. If I have to sleep on my other side, I could but it's very hard for me to fall asleep like that, and I often switch positions while asleep unconsciously. Any tips?

- Mine was too painful when I got the industrial done to sleep on the same side. I took a blanket, rolled it up, and placed it at my back so it would deter me from rolling over onto it. After about a week I was good to go on sleeping on that side. However, it#x27;s been two years and sometimes it gets too sore to sleep on the side with the industrial. I have definitely learned that it will always be sore if I constantly sleep on the same side every night instead of rotating sides. I learned the hard way about 2 weeks ago when I got the opposite side pierced at the rook. Good luck!

- Q: I need to build something using stainless steel tube or scaffolding tube. What is the cheapest place in the UK to get it ... with no minimum order quantities?Thanks.

- try okorder they sell stainless steel tubes for tubing. or truetube and eagletube , they supply with no minimum order ..

- Q: For my last piercing i think im gona make it worth it and get one of them ^^^ but i just looked on a website that describes them as both of them words i was just wondering are they completely different piercings ? and if so which one would be the better one to get?

- both are built to have supports

- Q: i really want this piercing but i am a wimp with pain lolbut 2 of my friends have got i one said it was sore and onesaid it wasnt and im getting it tomorrow

- It hurts extremely bad. I have 18 piercings and have never experienced that much pain at once. But the pain is white hot for a second then it fades into a throbbing as if someone pinched your ear extremely hard. Just make sure you watch the piercer get the area ready, make sure it's a clean needle and barbell. Infection is the last thing you want.

- Q: how long sould you wait to dye your hair after getting a scaffold piercing?

- I'd leave it until its fully healed. If it isn't healed then if you get the dye in the holes it can make it infected. I had a cartridge piercing and dyed my hair and it got infected and I had to take it out and now I have a big lump on my ear. So wait until its healed before dying your hair.il its healed before dying your hair.

- Q: Why do so many buildings in Manhattan have scaffolding on the street level?

- A few years ago pieces of building facades were falling onto the sidewalks. The city then insisted that all building facades be inspected and repaired. You are seeing the results of the inspections.

- Q: Other than it being cheaper and more eco friendly than steel scaffolding, why is bamboo used to make scaffolding in hong kong and china?

- It is relatively light and easy to handle and is found growing in many areas of China, so the cost is very low.

- Q: How much is the erection height of double row scaffold

- Two are better than the former.The following are given single row, double scaffolding erection height requirements:

- Q: Well my parents are going out of state soon and I want to get a Scaffold Ear Piercing but when i take the earring off does the piecing show?

- you will get your bellybutton pierced or you will get your 2nd ear lobe holes pierced in case you have already got your first ones.. my widespread is the cartilage...I even have my spectacular cartilage pierced and that i like it.. verify you get a small stud nevertheless...you dont wanna seem TOO flashy stable success!!

Send your message to us

Ringlock Ledger End Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords