PVC Ceiling Tiles Taupe - Rigid PVC Foam Board/PVC Crust Foam Sheet Waterproof for Decoration and Construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC Crust Foam Sheet

1.Feature

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

2.Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

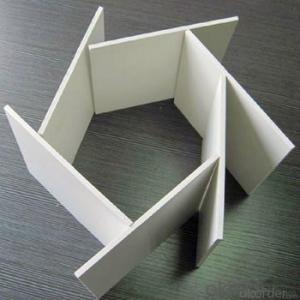

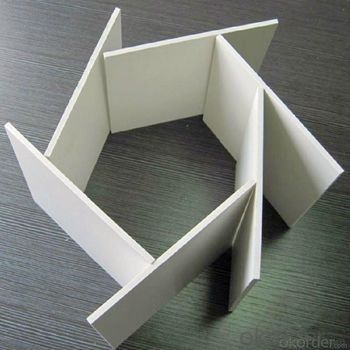

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

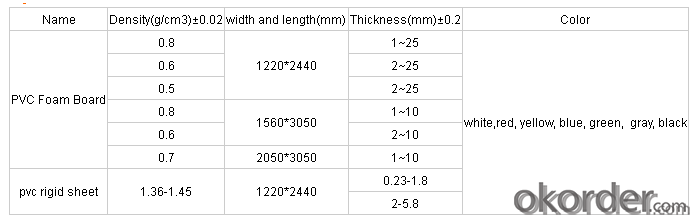

3.Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

4.FAQ

1, How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect.

2, Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery.

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

- Q: In addition to paint board, the door there are plastic panels, fire board, PVC board, solid wood and other styles. How can I choose?

- If so, can help you analyze the next, solid wood board prices a little high, used in the cabinet, then inconvenient, we should choose the principle of waterproof .. PVC board is cheap, but the quality is not .. fire board is generally used in the cabinet is the most.

- Q: What is the difference between oak bathroom cabinet and PVC bathroom cabinet?

- This is two different materials, completely two styles.

- Q: What is the difference between WPC and PVC flooring?

- WPC refers to the wood-plastic composite flooring, may be PVC / PE / PP + wood powder made out. PVC is PVC plastic, ordinary PVC flooring may not add wood powder.

- Q: Pvc board on the human body is not harmful

- Pvc board is not harmful to the human body. PVC is non-toxic harmless, only in the extreme temperature or combustion will produce harmful gases or substances PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: a restaurant that is partailly elevated. Is heat tape 'really' nessessary? If I wrap it tightly with insulatin then wrap it again with a plastic flex wrap, that ought to be okay, right? I'm not a plumber- just a basic maint. man. Any tips, ideas?

- The trick is to move the P traps up into the building(where there is heat) and replace the P traps in the lower extremes with a 90 elbow. No insulating needed. Water in a straight through drain pipe goes downward, no time to stay and freeze. If however above your head is the floor of the restaurant, you are in $hit. Insulation does not heat. It is just glass fibers(like hair). It will keep the cold in just like it will keep the heat in. You have had the experience. You can do 2 things. Build an enclosure(like a small room that has all the p-traps inside it, from ground to ceiling) and insulate that room. and then hang a light bulb in there with a 100W bulb burning 24/7 to supply the heat for that small room. Or use a trouble light. That is micro juice. costing a penny a month. I would also snag a thermometer and leave it in there at about the height of the lowest P trap(that will be the coldest one and check on it occasionally especially when it gets cold for you may need to put in extra heat if the 1 bulb is not enough because your room is not insulated well enough. So long as it is 33 degrees it is still water in the P traps. Just don't have the bulb near wood and you won't have a fire. Can't use heat tape on drain pipes. Only on supply lines So this could be a construction project of sorts. It is your call.

- Q: PVC door cut how bad repair

- PVC door repair has a special fill ash putty, make a good gray after the polished smooth And then use the same color paint spray paint treatment Generally more well-known brands will have material processing

- Q: PVC floor maintenance cycle is generally how long?

- It is enough to maintain once a year. Different stages of conservation methods 1, after the completion of the floor after the laying / maintenance before use (1) first on the floor surface of the dust, debris removed. (2) with a rubbing machine plus 3M red grinding or similar products low-speed cleaning (with a strong universal cleaning agent 1:20 diluted with water after the wipe machine), remove the floor surface protection wax, grease, dust and other dirt , With a suction machine to dry the sewage. (3) wash with water, dry. (4) If necessary, on the 1-2 layer of high strength wax.

- Q: How heavy the pvc board hangs on the wall

- With a large core board made of cloth made of a fake wall in the cloth with a nail nail lap

- Q: Pvc board to do the props hard, I want to do cos props

- Here with the 8mm board feel quite hard, afraid not hard on a layer of atomic ash

- Q: Pvc board and snowboard is a thing?

- Chevrolet also called Fulong board, his price and pvc poor a lot, you are not cheated ah

Send your message to us

PVC Ceiling Tiles Taupe - Rigid PVC Foam Board/PVC Crust Foam Sheet Waterproof for Decoration and Construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords