Reynolds Aluminum Foil 200 Sq Ft - Aluminum Foils, Aluminum Foil-Paper Grade AAA Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

2.Why you choose us?

Our quelity and service is best in China!

3.Specification and Application

ALUMINIUM FOIL

ALLOY:AA1***

AA3***

AA8***

TEMPER: O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

LIGHT GAUGE ALUMINUM FOIL

application:cigarette package, aseptic package, pouches, sachets

alloy:1235/8011/8079

temper:O

thickness&tolerance:0.006mm-0.009mm (±6%)

width&tolerance: 200mm-1650mm (±1mm)

mehanical properties: tensile strength (U.T.S)≥40Mpa, elongation≥1%

standard: GB/T3198 / ASTM-B209 /EN 546

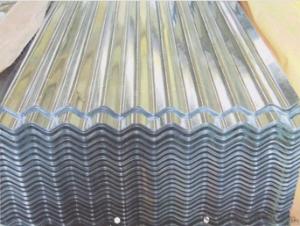

4.Pictures

5.FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

Production Flow of Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: I have everything I need to make fruit leather except nonstick liner and was wondering aluminum foil would workI also have parchment paper

- I'm looking for a mask last minute for my prom, and I know of only one store that sells nice onesEarthbound Trading CompanyAnd what sucks for me is that I don't have one where I live and they don't have an online store.

- Q: The aliminum in a package containing 75ft^2 of kitchen foil weighs approximately 12 ouncesAluminum has a density of 2.70 g/cm^3What is the approximate thickness of the aluminum foil in millimetersIt also gives how much 1 ounce is in grams, (1oz 28.4 g)Ive gotten all sorts of anwsers but just don't know if any are correct.

- a 1 lb box of powdered sugar less 1/3 cup1 stick of butter or margarine and about 13 oz of crunchy p.bmix and roll into ballsi dip mine in chocolate but it isn't necessary

- Q: I love italian bread dip, but can never quite get the right recipeWhat ingredients do you guys use?I've been using:olive oilbasalmic vinegaroregano

- There's lots you can doit just depends if you actually want to do themYou can call your friends and hang out witth them, go places, go ice skating, bowling, swimming, go to the mall and hang outgo to the beach, or if you like Rock music and screamo and metal, you can go to Warped Tour this summer.idk just a thoughtyou and your friends can have water baloon fights or paint fightsOr stuff that doesn't involve friends: Play music reallyyyyy loud and dance and sing or clean your room or house sorry that's all I can think of

- Q: For those that either use, or have tried this product?Does it really give 24hr protection? Lasts through the hot summer heat? Or a long swim? And is it supposed to leave my underarms feeling sticky?

- I thought id give my tid bit of knowledge about deodorant even though it doesn't fully answer your questionYou must change brands of deodorant like every month cuz eventually they all dont work0% aluminum is goodsticky - let it dry completely before putting arms down.?

- Q: so after all of my recent problems/issues:read my previous questions )i decided to , instead of using my phunnel bowl i decided to use the standard egyptian bowl that came with my hookah, and for a while of heating 2 coals around the edges of the bowl i didnt get any thick smoke or any big clouds,,, so i decided to push them both toward the middle of the bowl.after around 5 secondsmy hookah started to rip amazingly!!i had the biggest clouds ever for that hookah(KM) .BUTafter around 5 minutesall of a sudden the smoke started to get EXTREMLY HARSH, there was nothing i could do about it!i blew all the smoke out of the base to get rid of the harsh smokebut after i hit the hose again, it was still harsh! and i could tell from the bowl and foil that it had already burned the hell outta all my shisha!.SO PLEASE HELP ANY ADVICE!btw im done using that phunnel bowl , piece of crapsticking with my egyptian clay regular bowl.)

- After smoking a while, your shisha will eventually dry out and give harsh smokeThe hotter it burns, the faster it will dry outYou could try going for a good median between the two extremes you've already found (keep one coal at the edge and push one to the center) or stir the shisha after it starts getting harsh, since the top tends to burn quickly even while the bottom is still freshAlso check how your shisha is packedIf it's packed tightly, it will burn slower, but if it's too close to the top of the bowl, it will burn where it's close to the coalI like to pack my shisha to a medium density, and make sure to leave a fair amount of space to the top of the bowl so it doesn't get too closeThen I put the coals in the middlethe coals burn hot, but the shisha doesn't scorch, so it burns at a good enough speed to give off a lot of smoke, but doesn't scorch and burn your lungsAlso be sure to stir your coals every once in a while and knock off excess ash, so they stay a constant temperature.

- Q: So I was Looking at youtube makeup tutorial videos and I found some videos about dyeing your hair with kool-aidI thought that sounded weird at first, but I guess All you do it mix koolaid and conditioner together in a bowl, mix it till its smooth with no bumps, use a paint brush or something and put it in your hair, wrap that section with aluminum foil, leave on for like 8 hrs, then wash it out and it shouldn't be sticky or weird.So do you think this would be damaging?

- I did that once and my god.it worked the only thing is that it will smell for a long timeAnd it does damage from personal experience my hair i kool-aid was always bunched up and it looked like i slabbed gel on it and left it thereIt took days for it to wash off nasty stuff.

- Q: Why is aluminium a better conductor of electricity than magnesium?

- Each atom of aluminium has 3 valence electronsIn the metal, these electrons are free to moveEach atom of magnesium has only 2 valence electronsHence, there is less free mobile electrons in magnesium than in aluminium for carrying electrical charges.

Send your message to us

Reynolds Aluminum Foil 200 Sq Ft - Aluminum Foils, Aluminum Foil-Paper Grade AAA Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords