Resilient Seated Gate Valve (Z45X-16) on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ball Valve Description:

Threaded ball valve is closed is a ball, ball around the center line of the body as a rotation to achieve a kind of open and close the valve.

Ball valve in the line is mainly used for cutting, distribution, and change the flow direction of medium. Two type ball valve, three type ball valve, is widely used in recent years a new type of valve, the valve average installation. And ball valve is a kind of ball valves, threaded pipe connection is screwed connection, and flanged ball valves, welded ball valve, etc.

2. Main Features of the Ball Valve:

• Small flow resistance;

• Simple structure

• Small volume, light weigh

• Small volume, light weigh

• Easy to operate, open and close quickly, facilitate remote contro

• Easy maintenance, sealing ring, which generally remove easy to change

• Full open or full close, sphere and valve seat sealing surface and the dielectric isolation, medium through does not cause the valve sealing surface erosion.

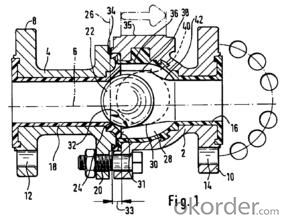

3. Images

4. Ball valve Specification

5.FAQ

1. What's are the characteristics of ball valve?

The distinct feature of a ball valve is the sealing surfaces between the gate and seats are planar, so ball valves are often used when a straight-line flow of fluid and minimum restriction is desired. The ball valve faces can form a wedge shape or they can be parallel.

2. What is the work principle of ball valve ?

The ball valve faces can form a wedge shape or they can be parallel. Ball valves are primarily used to permit or prevent the flow of liquids, but typical ball valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, ball valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Ball valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What type of flange does it fit with the gate valve?

- According to the welding plate flange, flange material selection of piping material.

- Q: What are the specifications of the gate valves? Does the work pressure need to be marked separately?

- 5- dark pole single wedge gate valve, 6- dark bar wedge gate valve 7-, dark bar parallel gate valve, parallel gate valve 9- dark bar;5, sealing materials or lining materials were used R- T- austenitic stainless steel, copper alloy, X- rubber, S- plastic, N- nylon, F- fluorine plastic, H-Cr series stainless steel, hard alloy Y-, J- rubber, M- Monel alloy, Tc- ceramics;6, the body material code Z- K- gray cast iron, malleable cast iron, Q- ductile iron, copper and T- alloy, C- steel, P- chromium nickel stainless steel, R- stainless steel chromium nickel molybdenum, chromium molybdenum vanadium steel V-.For example: electric, flanged, rod wedge gate valve, sealing surface material by direct processing, nominal pressure PN0.1MPa of the valve body is made of grey cast iron gate valve: Z942W-1 electric wedge gate valve.

- Q: The difference between flanged gate valve and common gate valve

- General diameter of more than 50 with flanges, inspection wells, main pipes, trenches... Must use flange gate valve, good operation, good replacement.

- Q: What is the difference between gate valves Z41W-16R and Z41W-16P?

- According to JB/T308P stands for Cr-Ni stainless steelR stands for Cr-Ni-Mo stainless steelCr-Ni stainless acid resistant steel has CF8, CF3, F304, F304L, which applies to the medium of work, such as nitric acid oxidation acid.Cr-Ni-Mo stainless acid resistant steel has CF8M, CF3M, F316 and F316L, which is suitable for working medium, such as acetic acid and reducing acid.

- Q: Why? God, can you explain to me in detail why?

- The exit of the general pump is the first soft connection (shock absorber), followed by the check valve, and then the partition valve (such as butterfly valve, gate valve, cut-off valve, etc.), this is not the final answer.The question is interesting, and no corresponding information has been found in the relevant standards. We have also discussed the related issues, but differences of opinion is relatively large, the advantages of 1, first installed check valve installed after the valve or butterfly valve, check valve, can be protected, especially in a parallel pump, when the pump does not start, another pump starts when the impact force is gate valve or butterfly valve bear, disadvantages: gate valve or check valve who will protect? There have been a case of butterfly valve is broken. 2, first installed gate valve or butterfly valve installed after the check valve, advantages: can protect the butterfly valve or gate valve, the impact on the check valve to bear. Disadvantages: check valve who will protect, check valve by pressure difference switch, if the high pressure high pressure pipe, pump, if the flow is not stable, so check valve will repeatedly switch, will affect the check valve life. Personal opinion: check valve, check valve performance now have changed, many are using the slow closing check valve, so the impact force is two aspects to bear, because exports are not fully open the valve or butterfly valve, so you can put in check after the gate valve or butterfly valve valve. If not the slow closing check valve installed in the valve or the best after the butterfly.

- Q: What are the main types of gate valves?

- sealing surface configuration can be divided into wedge gate valve and parallel gate valve, wedge gate type valve can be divided into: single gate type, dual gate plate and the flexible gate type; parallel gate valve can be divided into single and dual gate gate plate.

- Q: What does gate valve do?

- Valve in the pipeline can only be fully open and fully closed off, can not be adjusted and the throttle. Gate valve is a valve used in a wide range, generally more than 50mm caliber DN block device is selected it, sometimes cut off very small aperture devices are used to gate valve, gate valve is used as cut-off media, when in full flow through the whole, when the media is running a minimal pressure loss. Gate valves are normally used in situations where they do not need to be frequently opened and closed, and the gate is fully open or fully closed. Not used as an adjustment or throttling. For high speed moving medium, the gate can cause the vibration of the gate under the condition of partial opening, and the vibration may damage the sealing surface of the gate and the valve seat, while throttling will cause the gate to suffer the erosion of medium.

- Q: What kind of copper gate valve copper content standards, there are no national standards?

- Please refer to: GB/T12225-2005 "general purpose valve, copper alloy casting technical specification" and GB/T 15116-1994 "die casting copper alloy"

- Q: What is the difference between an elastic gate valve and a rigid gate?

- One is cast iron, intermediate rubber gate, one is cast steel, and the other is steel flashboard,

- Q: Generally, how big is the diameter of the installation flange plate gate valve?

- Under normal circumstances:Flanged gate valves for piping over DN50,DN50 (below) can be made of wire or gate valves, or flanged gate valves (flanged valves or welded gate valves)

Send your message to us

Resilient Seated Gate Valve (Z45X-16) on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches