GATE VALVE RISING STEM RESILIENT SOFT SEATED DUCTILE IRON BS5163

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Medium Pressure |

| Power: | Manual | Material: | Ductile Iron | Temperature of Media: | Normal Temperature |

| Media: | Base | Port Size: | flanges | Place of Origin: | Shanghai, China (Mainland) |

| Model Number: | VA006 | Brand Name: | SPS | name: | ansi 125 / 150 gate valve |

| specification: | ansi 125 valve | type: | rising stem | seal: | resilient soft seated |

| kind: | gate valve | pressure: | PN10/16/25 | standard: | ansi 125/150 |

| face to face standard: | ansi B16.10 | flanges: | ansi B16.1/16.5 |

1) Product information: the gate valves supplied are mainly used for adjusting water, steam, oil, gas, and natural gas in chemical industries

2) Standards: AWWA C509/C515, DIN3352 F4/F5, BS5163, BS5150,SABS 664

3) Connection type: flanged type, push-on type, mechanical joint type, plain ends type

4) Material:

a) Body/Bonnet : Ductile Iron GGG500-7

b) Wedge : DI , core fully vulcanized with NBR or EPDM rubber

c) Wedge Nut : Brass

d) Stem : Stainless steel , BS970 431S29 or DIN17440x20Cr13

e) Gasket/O-ring : NBR/EPDM

f) Washer : Carbon steel or Stainless steel .

5) Size: DN50~DN1200/2" ~ 48"

6) Pressure grade: PN10, PN16,PN25,ANSI 125/150

7) Coating:

a) Fusion-bonded epoxy 200-250 microns inside and out side

b) Coating as per customers' requirement

8) Package :Plywood case.(each pc into one bubble plastic bag, several pcs into Plywood case).

Product Name | rising stem resilient soft seated ansi 125/150 gate valve |

Material | CI/DI |

Color | blue/red/gray/Coating as per customers' requirement |

Standard | AWWA C509/C515, DIN3352 F4/F5, BS5163, BS5150,SABS 664 |

Connection type | flanged type, push-on type, mechanical joint type, plain ends type |

Package | Plywood case.(each pc into one bubble plastic bag, several pcs into Plywood case). |

Size | DN50~DN1200/2" ~ 48" |

Used | adjusting water, steam, oil, gas, and natural gas in chemical industries |

- Q: What gate DH10016, AM

- The first Z represents the gate valve (the initial consonant of the Chinese phonetic alphabet for the gate); the second 2 represents the drive mode of the valve, that is, electro hydraulic drive.

- Q: What does gate valve Z44T-10-200 code mean?

- The meaning of the model is standard, the landlord himself to check the JB/T308 standard, Baidu library some, and is free to download:JB/T 308-2004 valve type method of preparation clear EditionHttp://wenku.baidu /view/5f798850ad02de80d4d84036.htmlZ = gate valve4 = connection: flange4 = structure form: double gateT = sealing surface material: Copper10 = nominal pressure: 1.0MPa, followed by no letters indicate body material: Cast Iron200 = nominal path: DN200

- Q: Why is gate valve or butterfly valve used for water pump?

- General pressure is small, use the butterfly valve, when the pressure is big, use the gate valve. The two main function of the valve is to adjust the flow and easy to overhaul.Zibo Boshan new Duke water supply equipment

- Q: How big valves and fittings need flange installation, such as gate valves, DN50, DN80 and the like?.

- Specifically, look at the pressure of the pipeline, the environment is not big, if large with flange connection, usually hoop or wire can be connected.

- Q: What are the main types of gate valves?

- sealing surface configuration can be divided into wedge gate valve and parallel gate valve, wedge gate type valve can be divided into: single gate type, dual gate plate and the flexible gate type; parallel gate valve can be divided into single and dual gate gate plate.

- Q: What is gate well?

- Gate valve well: it is a irrigation network system which aims at improving water utilization and efficiency, aiming at the construction of water saving and high-efficiency agriculture as well as scientific and technological innovation as well as convenient operation and management.

- Q: Is the gate valve flanged?

- The most commonly used gate valves are threaded connections, flanged connections, and welded connections.Like the outer thread connection, the clamp connection, the card sleeve is seldom used.

- Q: What kind of valve is gate valve? Is it different from the cut-off valve?

- Gate valve and the role of the cut-off valve, are playing a role in isolation. The difference is that the gate valve and the cut-off valve are constructed differently. Fluid from the gate valve flow and flow direction is straight, there is no change in direction, but in the cut-off valve is from the bottom of the valve flow into the flow from the upper part of the spool.

- Q: Gate valve z11h/y-16 what does that mean?

- Product Name: internal thread gate valveItem number: Z11HProduct specification: DN15-50Product pressure: 1.6MPa-2.5MPaMaterial: cast iron, cast steel, stainless steelInternal thread gate valve nominal pressure 2.5Mpa, applicable temperature range -20-232-350, applicable medium: water, oil, gas and certain corrosive liquid (W.O.G), thread type G.NPT.BSPT.BSP.DIN259/2999.

- Q: What are the standards for the execution of cast iron dark pole gate valves?

- Standard Specification for cast iron blind rod gate valves:1, design and manufacture: according to the provisions of GB/T12234-892, structural length: according to the provisions of GB/T12221-893, flange size: according to the provisions of JB79 GB/T9112-91314, inspection and test: according to the provisions of JB/T9092-99 GB/T13927-92Drive mode: manual, electric, gear drive;

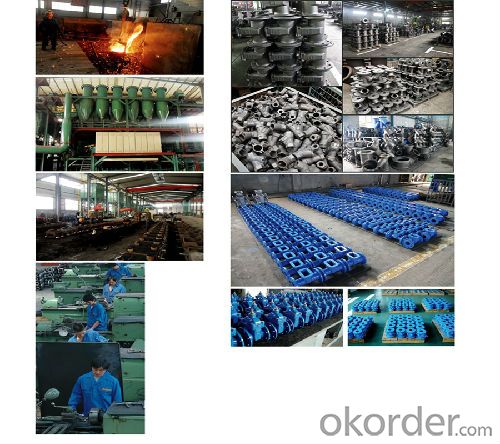

1. Manufacturer Overview

| Location | Anhui,China |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | South America; Western Europe; Eastern Europe; Southeast Asia; the Middle East |

| Company Certifications | ISO9001;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 44000 square meter |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GATE VALVE RISING STEM RESILIENT SOFT SEATED DUCTILE IRON BS5163

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords