Resilient seated Gate valve (Small Type) BS5163

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

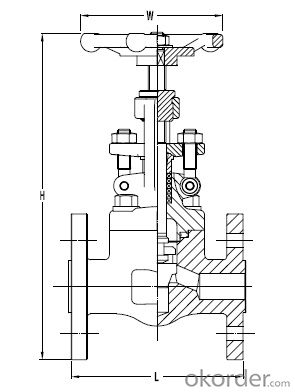

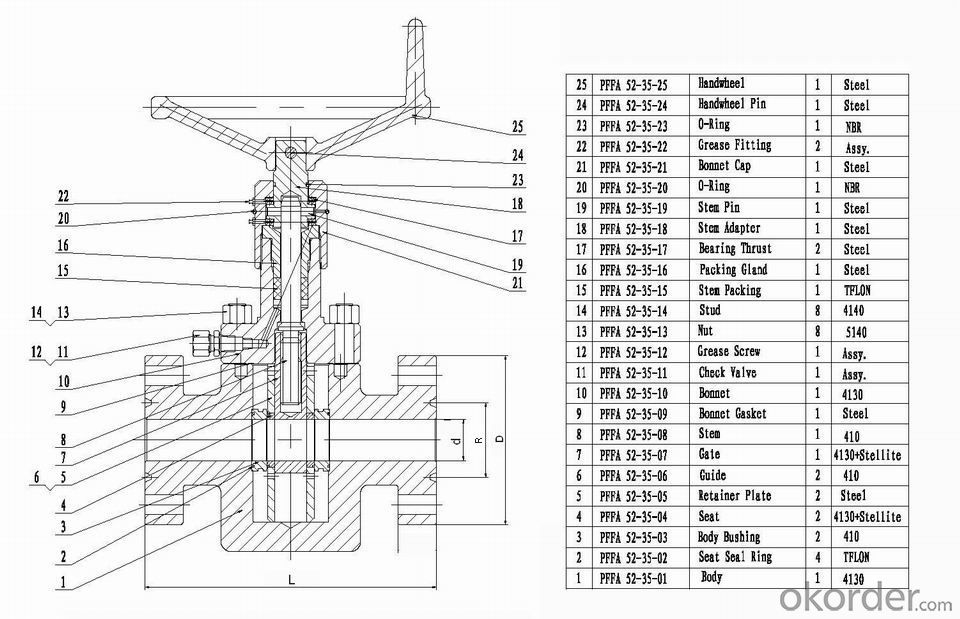

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What valve should be used to test the water valve?

- 3, ball valve (ball valve should be a cut-off valve in the marine and marine field), standard GB/T21465-2008 "valve terminology" is defined as: opening and closing parts (ball) driven by the stem, and around the valve axis for rotation of the valve. Can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media.

- Q: What is the difference between the adjustable range of valve 50:1 and 100:1?

- Adjustable ratio is also called adjustable range, if to R to indicate, then R=Qmax/Qmin should pay attention to the minimum flow, Qmin and leakage of different meanings. The minimum flow refers to the lower limit of adjustable value, it is generally the maximum flow rate of Qmax 2%~4%, and the leakage is fully closed when the leak valve, it is only the maximum flow rate of 0.1%~0.01%.Adjustable range 100:1 generally can not reach, the accuracy of this valve is very high.

- Q: How do you calculate the valve wall thickness, pressure, and other valve design calculations in a spreadsheet?

- Which standard does the wall thickness refer to? ASME B16.34?Design and calculation depends on what standard you chooseOr have you found the standard yourself and read it yourself?You choose what standards, design parameters reference, interpolation or fitting, how to fit, are their own sayI wrote a excel series of valve calculations, it does not take long to writeFor long-term useIn order to improve efficiencyOr write your own database program is better

- Q: Is the valve galvanized?

- Butterfly valve gate, some hot-dip galvanized, and other valves are not.

- Q: What does the "Z45T-16" valve mean?

- Z - gate valve4 - flange connection5 - Dark pole, stem non lifting (gate valve structure)T - copper alloy, valve sealing face code16 - pressure code, 1.6MPaMaterial code for grey cast iron valves of nominal pressure less than or equal to PN16 shall be omitted in model preparation.May refer to JB/T 308 valve model compilation method

- Q: Which valve can play a good regulatory role?

- A wide range of valves, the function is different, although like conventional butterfly valve, ball valve can play a regulatory role, but their role is not linear, so if you need to adjust the precision of the valve, it is best to select the control valve.

- Q: How big valves are used in the DN90 pipeline?

- DN is the nominal diameter, only DN80, DN100.It is estimated that your pipe is outside diameter 89mm, that is DN80, that is to choose DN80 valve.

- Q: What should be checked before using the valve?

- 5, check valve disc or spool movement is flexible and accurate, no bias, displacement or skew phenomenon6, spring-loaded safety valve should be sealed, positioning lever type safety valve should have the weight of the device7, rubber lining, lining enamel and plastic lined valve body surface should be smooth, the lining layer and the substrate firmly, no crack, blister defects, using high frequency electric spark generator to inspect the lining surface, not found in liner breakdown (white flash phenomenon) is qualified8, the valve flange sealing surface should meet the requirements, and shall not have radial scratches

- Q: How to better maintain the valve?

- Use and maintenanceThe maintenance of the aim is to extend valve life and ensure reliable opening and closingThe stem threads, often with the stem nut friction, to a little yellow dry coating oil, molybdenum disulfide or graphite, lubricationWe do not often open and close the valve, but also on a regular basis handwheel on the stem threads to add lubricant to prevent bitingThe outdoor valve, to increase the protection sleeve on the stem, to rain, snow, dust and rustIf the mechanical valve system to be fixed, to add time to the gearbox oil

- Q: Can the angle valve of York central air conditioner be replaced by other valves?

- Definitely. But I want you to tell me what you're doing, or give me a picture. I can give you some advice

Send your message to us

Resilient seated Gate valve (Small Type) BS5163

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches