Reinforcement Steel Rebar Turkey/Steel Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

Round,U Channel,Square,C Channel,Hexagonal,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

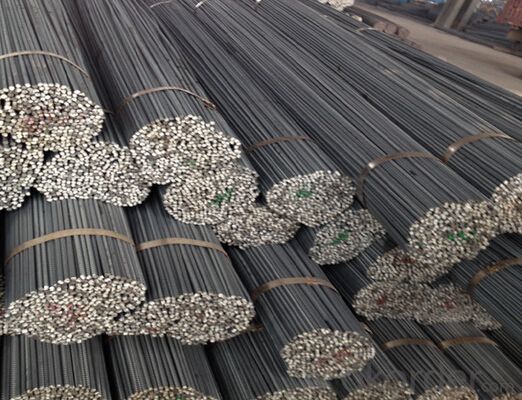

Reinforcement Steel Rebar Turkey/Steel Reinforcement

Details of the Reinforcement Steel Rebar Turkey/Steel Reinforcement

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the Reinforcement Steel Rebar Turkey/Steel Reinforcement

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the Reinforcement Steel Rebar Turkey/Steel Reinforcement

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the factors that can affect the lifespan of steel rebars in concrete structures?

- Several factors can impact the lifespan of steel rebars in concrete structures. Firstly, the structure's concrete quality and composition are significant. If the concrete is of low quality or contains harmful chemicals, it can corrode the rebars, leading to a shorter lifespan. During construction, it is essential to properly proportion and cure the concrete mixture. Secondly, the rebars' lifespan is greatly affected by the exposure conditions of the concrete structure. Factors like humidity, temperature fluctuations, and the presence of aggressive substances such as chloride ions or carbon dioxide can accelerate corrosion. Structures in coastal or industrial areas are especially vulnerable due to high salt levels in the air or pollutant presence. Thirdly, the design and construction practices employed have a significant impact on rebars' longevity. Adequate cover thickness, which is the distance between the rebar surface and the concrete's outer face, is crucial. Insufficient cover thickness can result in inadequate corrosion protection. Additionally, effective drainage systems should be incorporated into the design to prevent water accumulation around the rebars, as stagnant moisture accelerates corrosion. Furthermore, maintenance practices also affect rebars' lifespan. Regular inspections, cleaning, and repairs help identify and address issues before they worsen. The application of protective coatings or the use of corrosion inhibitors can also extend rebars' lifespan. Lastly, the type and quality of the rebars themselves are important factors. Rebars with higher carbon and alloying elements are generally more resistant to corrosion. The manufacturing process quality and the presence of impurities can also impact rebars' durability. In conclusion, the lifespan of steel rebars in concrete structures can be influenced by several factors, including concrete quality, exposure conditions, design and construction practices, maintenance, and rebars' quality. Proper attention to these factors ensures the longevity and structural integrity of concrete structures.

- Q: Are there any limitations on using steel rebars in cold climates?

- Yes, there are some limitations on using steel rebars in cold climates. The main concern is the potential for corrosion due to the presence of moisture, salt, and de-icing chemicals commonly used on roads and bridges during winter. When steel rebars are exposed to these elements, they can rust and weaken over time, compromising the structural integrity of the concrete. To mitigate this issue, several measures can be taken. One common practice is to use epoxy-coated rebars, which provide a protective layer against moisture and chemicals. Additionally, stainless steel rebars can be used, as they are highly resistant to corrosion. However, these options can be more expensive than traditional steel rebars. Furthermore, the construction process in cold climates can also present challenges. Concrete cures and gains strength more slowly in low temperatures, which can impact the overall project timeline. Special precautions, such as heating the concrete or using accelerators, may be necessary to ensure proper curing. It is important to consult local building codes and regulations specific to cold climates to ensure compliance and safety. Engineering professionals experienced in cold weather construction practices can provide valuable insights and recommendations to address the limitations associated with using steel rebars in these conditions.

- Q: What are the different types of steel rebars used in precast concrete constructions?

- Precast concrete constructions commonly utilize various types of steel rebars to enhance the strength and durability of the structures. The following are some of the commonly employed rebars along with their distinctive features: 1. Mild Steel Rebars: These rebars, widely used due to their affordability and easy availability, possess a low carbon content. They are suitable for most precast concrete applications. 2. High Strength Deformed (HSD) Rebars: HSD rebars, crafted through the hot rolling process, exhibit a superior yield strength compared to mild steel rebars. Their surface is characterized by deformations that enhance their grip with concrete. These rebars are commonly employed in heavy-duty structures or situations necessitating additional strength. 3. Carbon Steel Rebars: Carbon steel rebars, made from carbon steel alloys, possess a higher carbon content than mild steel rebars. Consequently, they offer improved strength and durability. They are often utilized in precast concrete constructions requiring high tensile strength. 4. Epoxy-Coated Rebars: To safeguard against corrosion and extend their lifespan, these rebars are coated with an epoxy layer. Epoxy-coated rebars find common application in precast concrete constructions exposed to harsh environments or possessing high moisture content. 5. Stainless Steel Rebars: Constructed from stainless steel alloys, these rebars exhibit excellent corrosion resistance. They are employed in precast concrete constructions exposed to corrosive substances such as seawater or chemicals. It is crucial to select the appropriate rebar type for a precast concrete construction, considering specific project requirements such as load-bearing capacity, durability, and environmental conditions. Collaborating with a structural engineer or construction professional can aid in determining the most suitable rebar type for a particular application.

- Q: How do steel rebars affect the overall fire safety of a structure?

- Steel rebars can have both positive and negative effects on the overall fire safety of a structure. On one hand, steel rebars can contribute to the strength and stability of the structure, helping it withstand the impact of a fire and preventing structural collapse. This is especially important in high-rise buildings or structures that are vulnerable to fire hazards. Moreover, steel rebars have a high melting point, making them more resistant to heat compared to other building materials. This can help slow down the spread of fire and provide additional time for evacuation or firefighting measures. However, steel rebars can also have some negative effects on fire safety. When exposed to high temperatures, steel expands, which can lead to structural deformations and potential failure of the rebars. This can compromise the integrity of the structure and increase the risk of collapse. Additionally, steel rebars conduct heat, which means they can transfer heat from the fire to other parts of the structure. This can cause localized heating and weaken nearby materials, potentially leading to a faster spread of fire within the building. To mitigate these negative effects, fire-resistant coatings or fireproofing materials can be applied to the steel rebars. These coatings can provide insulation and protect the rebars from high temperatures, delaying their failure and reducing the risk of structural collapse. In conclusion, while steel rebars can enhance the overall fire safety of a structure by providing strength and stability, they also have some drawbacks. Proper fire protection measures, such as fire-resistant coatings, are crucial to ensure the rebars perform optimally in the event of a fire.

- Q: How are steel rebars classified based on their shape?

- Steel rebars are classified based on their shape into different categories such as plain round bars, deformed bars, and ribbed bars.

- Q: How do steel rebars resist shear forces in concrete structures?

- Steel rebars resist shear forces in concrete structures by providing additional strength and reinforcement. The rebars are embedded within the concrete, creating a composite material that can withstand shear stresses. The steel rebars help to distribute the shear forces evenly throughout the structure, preventing cracks and failure. Additionally, the high tensile strength of the steel rebars allows them to resist deformation and displacement under shear loads, ensuring the stability and integrity of the concrete structure.

- Q: Can steel rebars be used in structures with heavy snow loads?

- Indeed, structures burdened with heavy snow loads can incorporate steel rebars. These rebars are commonly employed in construction to fortify concrete structures and augment their strength. When designing structures in regions prone to heavy snowfall, engineers carefully consider the weight of the snow and ensure that the structure is equipped to bear the additional load. Steel rebars possess the strength necessary to endure substantial loads, allowing them to reinforce the concrete within a structure and enhance its resistance against snow-induced forces. Furthermore, steel rebars aid in distributing the load evenly throughout the structure, mitigating the risk of failure or collapse. Nevertheless, it is crucial to seek guidance from a structural engineer or a knowledgeable professional familiar with local building codes and regulations to guarantee the proper design and construction of the structure to meet the specific requirements for snow loads in the area.

- Q: What is the typical cost of steel rebars per ton?

- The typical cost of steel rebars per ton can vary depending on various factors such as the type and grade of rebar, market conditions, and location. However, as of 2021, the average price range for steel rebars is approximately $600 to $900 per ton.

- Q: Are there any environmental concerns related to the production of steel rebars?

- The production of steel rebars raises several environmental concerns, including the significant energy requirement for steel production. To produce steel, large amounts of fossil fuels like coal and natural gas are used, contributing to greenhouse gas emissions and climate change. Another concern is the extraction and mining of iron ore, the main raw material for steel production. This process can result in deforestation, habitat destruction, and soil erosion. Moreover, mining generates substantial waste material that can contaminate nearby water sources. In addition, the steel production process emits air pollutants such as particulate matter, sulfur dioxide, and nitrogen oxides. These pollutants can harm air quality and human health, causing respiratory problems and contributing to the formation of smog. It is worth noting that the steel industry is taking steps to address these environmental concerns. For instance, many steel producers are adopting more energy-efficient technologies and exploring alternative energy sources to reduce carbon emissions. Additionally, the recycling of steel is becoming more widespread, conserving resources and reducing the environmental impact of steel production. Overall, although the production of steel rebars does present environmental concerns, ongoing efforts are being made to mitigate these impacts and make the process more sustainable.

- Q: How do steel rebars bond with concrete?

- Steel rebars bond with concrete through a process called mechanical interlocking, where the rough surface of rebars provides a strong grip with the concrete. Additionally, during the curing process, a chemical reaction occurs between the alkaline environment of concrete and the iron surface of the rebars, forming a layer of iron oxide that further enhances the bond strength.

Send your message to us

Reinforcement Steel Rebar Turkey/Steel Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords