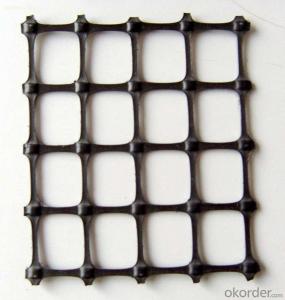

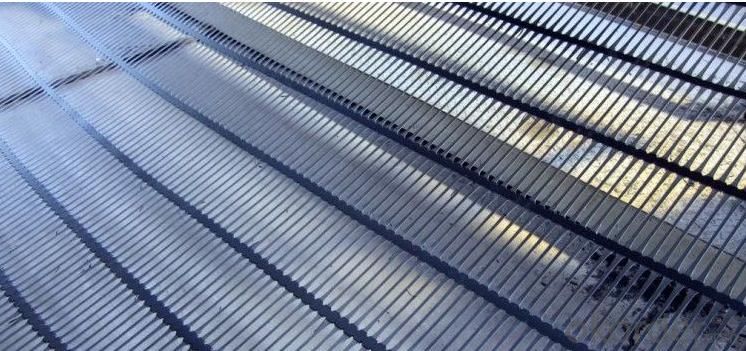

Reinforcement Geogrids - PP Uniaxial Geogrids / Polypropylene Uniaxial Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(ux) uniaxial geogrids

PP Uniaxial geogrid is expecially designed for soil reinforcement.it is sheet extruded,punched,heated and stretched from polypropylene,it has high tensile strength,excellent interlock capacity and deformation.

Speicification of PP Uniaxial Geogrid

| Property | TGDG | TGDG | TGDG | TGDG | TGDG | TGDG | |

| 35 | 50 | 80 | 100 | 110 | 120 | ||

| Ultimate tensile strength | kN/m | 35 | 50 | 80 | 100 | 110 | 120 |

| Elongation at maximum load | % | 10 | |||||

| Tensile strength at 2 % elongation | kN/m | 9 | 10 | 23 | 29 | 30 | 35 |

| Tensile strength at 5 % elongation | kN/m | 18 | 25 | 44 | 55 | 58 | 65 |

| Creep Limit Strength | KN/m | 15 | 21 | 30 | 39 | 40 | 46 |

| Minimum Carbon Black | % | 2 | |||||

| Property | TGDG 150 | TGDG | TGDG | TGDG | TGDG | TGDG | |

| 170 | 200 | 220 | 240 | 300 | |||

| Ultimate tensile strength | kN/m | 150 | 170 | 200 | 220 | 240 | 300 |

| Elongation at maximum load | % | 10 | |||||

| Tensile strength at 2 % elongation | kN/m | 39 | 45 | 55 | 59 | 65 | 90 |

| Tensile strength at 5 % elongation | kN/m | 77 | 90 | 110 | 120 | 132 | 182 |

| Creep Limit Strength | KN/m | 49 | 57 | 64 | 71.5 | 79 | 100 |

| Minimum Carbon Black | % | 2 | |||||

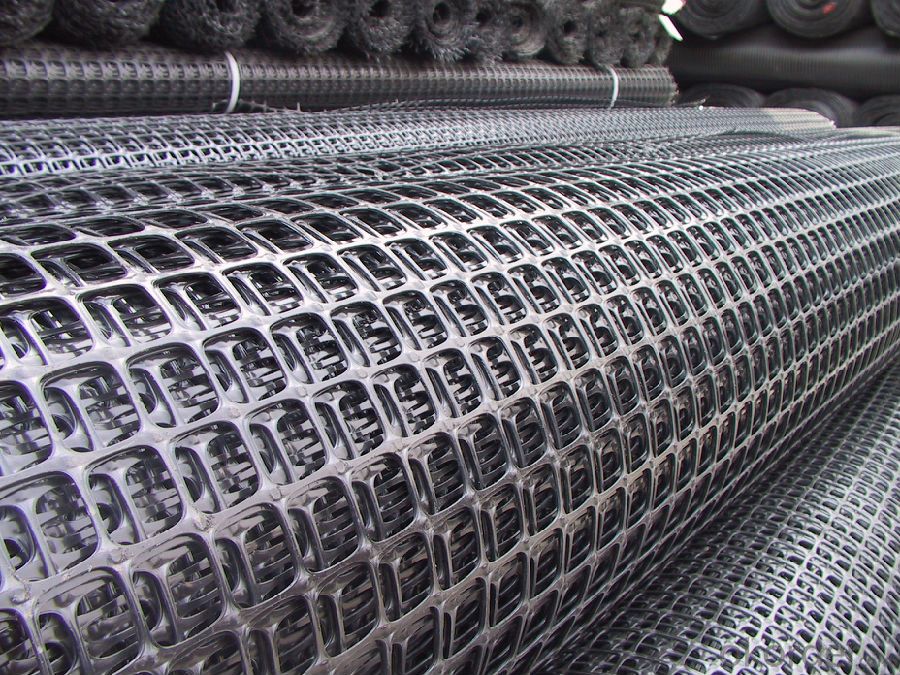

| Standard Roll Dimensions | |||||||

| Roll Length(m) | 50m | ||||||

| Roll Width(m) | 1m,2m,3m | ||||||

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are often employed to reinforce and stabilize tailings dams, prevent soil erosion, and improve the overall stability of the tailings impoundment. They can also assist in controlling the settlement and deformation of the tailings, providing a reliable and effective solution for tailings management in the mining industry.

- Q: What are the design considerations for geogrid-reinforced slopes?

- Some of the design considerations for geogrid-reinforced slopes include the type and strength of the geogrid material, the slope angle, soil properties, and the expected load and traffic conditions. The design also needs to account for factors such as water drainage, vegetation, and long-term stability. Additionally, proper installation techniques and quality control measures should be considered to ensure the effectiveness and durability of the geogrid reinforcement system.

- Q: What is the GDL geogrid

- First, the characteristics of uniaxial tensile plastic geogrid:1, the polymer into a linear state and the formation of a uniform distribution, high strength of the node of the long elliptical mesh integral structure. This kind of structure has high tensile strength and rigidity, and it provides the ideal chain system of bearing and diffusion of soil;

- Q: Light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.

- It's a double decker!

- Q: How do geogrids improve the stability of railway embankments?

- Geogrids improve the stability of railway embankments by providing reinforcement and preventing soil movement. They distribute the load more evenly, reducing the potential for settlement and slope failure. Additionally, geogrids increase the bearing capacity of the embankment, enhancing its overall stability and longevity.

- Q: Can geogrids be used in slope protection systems?

- Yes, geogrids can be used in slope protection systems. Geogrids are commonly used to reinforce slopes by providing stability and preventing soil erosion. They can be installed horizontally or vertically to improve the strength of the soil and enhance the overall performance of slope protection systems.

- Q: Are geogrids resistant to alkali degradation?

- Yes, geogrids are typically resistant to alkali degradation.

- Q: How do geogrids improve the performance of reinforced soil retaining walls?

- Geogrids improve the performance of reinforced soil retaining walls by adding tensile strength and enhancing stability. They are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement to the soil mass. When geogrids are incorporated into the retaining wall design, they effectively distribute the applied loads, reducing the stress on the soil and preventing wall failure. Additionally, geogrids increase the overall stiffness of the reinforced soil, minimizing deformation and settlement. This reinforcement technique enables the construction of taller and more structurally sound retaining walls, ensuring long-term stability and improved performance.

- Q: What is the effect of installation damage on geogrid performance?

- Installation damage can have a significant impact on geogrid performance. When geogrids are improperly installed or handled, they can sustain damage such as tears, punctures, or stretching. These damages can weaken the geogrid's structural integrity and compromise its ability to provide reinforcement and stabilization in soil or aggregate applications. As a result, the geogrid may not be able to withstand the intended loads and stresses, leading to reduced performance and potential failure of the geosynthetic system. Therefore, proper installation techniques and careful handling are crucial to ensure optimal geogrid performance and longevity.

- Q: How long do geogrids typically last?

- Geogrids typically have a lifespan of 20 to 50 years, depending on factors such as installation quality, environmental conditions, and the specific application they are used for.

Send your message to us

Reinforcement Geogrids - PP Uniaxial Geogrids / Polypropylene Uniaxial Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords