Reinforcement Fabric Made from Basalt Fiber for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fabric Made from Basalt Fiber Introduction

Continuous basalt fiber fabric is made by impregnating woven basalt fiber scrim with asphalt and then drying to be made.

In the normal temperature, the ratio of the elastic modulus between the basalt fiber concrete and the asphalt concrete is 24: 1.

Advantages of Fabric Made from Basalt Fiber

Basalt fibre concrete has the excellent resistance to deformation, the elongation at break is about 3.1%. Basalt Fiber owns the high-temperature resistance, frost resisting resistance (-260~650 ℃), the same thermal expansion coefficient with the asphalt concrete, the high tensile strength, ultraviolet resistance, the stable chemical resistance, ageing resistance. The stirring temperature of the asphalt concrete is up to 190℃. The high-temperature Basalt fiber is the best alternative of the polyester fiber. It can satisfy the asphalt stirring temperature (190 ℃), and it is the excellent construction material for reinforced cement & concrete, and it has the outstanding penetration resistance.

Basalt fabric/geogrid/geotextile is more durable than metallic and glass-fiber reinforcement due to basalt fiber’s excellent performance.

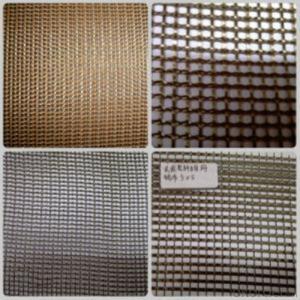

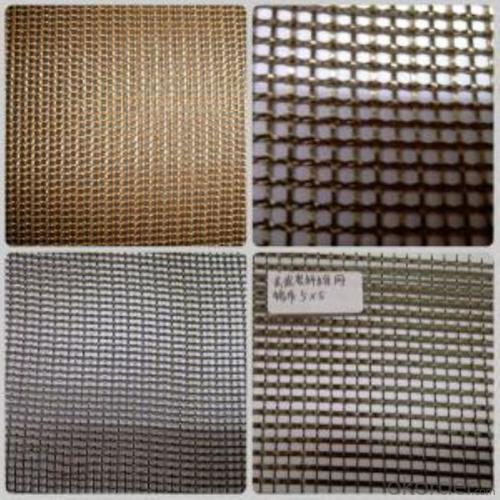

Specifications of Fabric Made from Basalt Fiber

Item No. | Weight (g/m2) | Size (mm) | Thickness (mm) | Width (mm) | Roll Length (m) |

CMAX-250 | 250 | 5X5 | 0.6-0.7 | 300-2000 | 50m~100m |

CMAX-120 | 165 | 10X10 | 0.7-0.8 | 300-2000 | 50m~100m |

CMAX-300 | 350 | 25X25 | 0.8-0.9 | 300-2000 | 50m~100m |

Application of Fabric Made from Basalt Fiber:

-laying of cement concrete pavement

-the reinforcement of the piers, dams,road and buildings

-building surface drywall joints

-cement mortar or concrete pouring

FAQ:

1. Which payment do you accept?

For you convinience, our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

4. When will you reply my request?

You are our expected customer, we’ll reply your request within 24hours. Please feel free to contact us at any time.

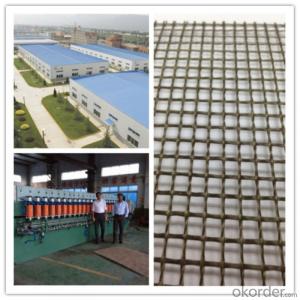

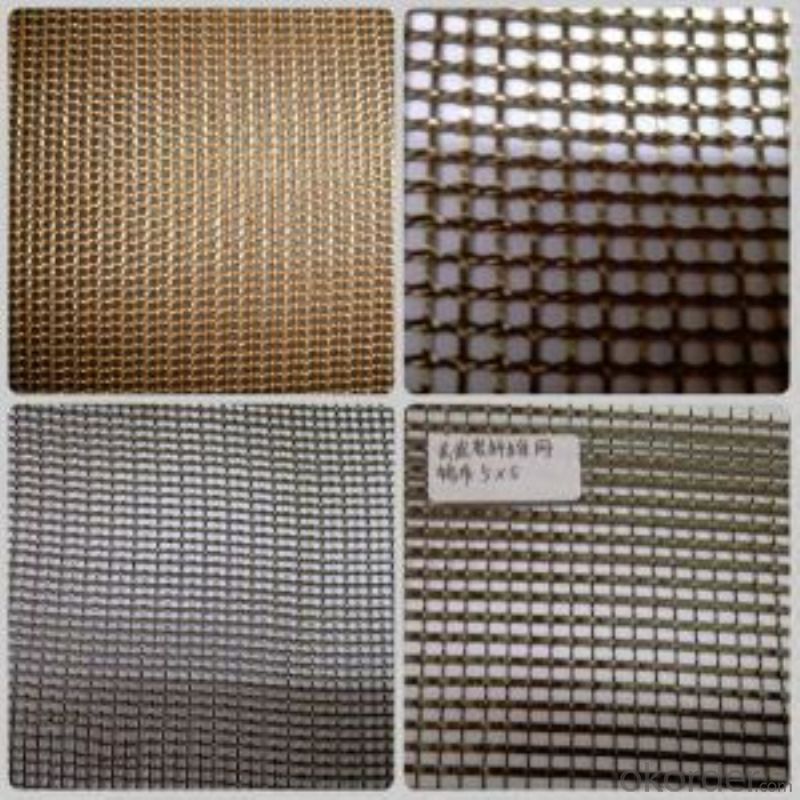

Photo of Fabric Made from Basalt Fiber:

- Q: Basalt fiber reinforced steel and steel which expensive

- Basalt fiber, is the basalt stone in the 1450 ℃ ~ 1500 ℃ after melting, through the platinum and rhodium alloy wire drawing from the high-speed drawn from the continuous fiber. Similar to the glass fiber, its performance between high-strength S glass fiber and E-alkali E glass fiber between the natural color of natural basalt fiber is generally brown, some like gold. Basalt fiber is a new type of new environmentally friendly green high-performance fiber material, which is composed of silica, alumina, calcium oxide, iron oxide and titanium dioxide and other oxides of basalt stone in the high temperature melting, Drawn by. Basalt continuous fiber is not only good stability, but also has electrical insulation, corrosion resistance, anti-burning, high temperature and other excellent performance. In addition, the basalt fiber production process of waste less, less environmental pollution, product waste can be directly transferred to the ecological environment, without any harm, and thus is a veritable green, environmentally friendly materials. China has the basalt fiber as China's focus on the development of one of the four major fibers in China, basically achieved industrial production. Basalt continuous fibers have been widely used in fiber reinforced composites, friction materials, shipbuilding materials, insulation materials, automotive industry, high temperature filter fabrics and protection areas.

- Q: The difference between basalt and basalt

- Alkaline basalt Basal basic volcanic rock search. Thalb than the average basalt, while silica, calcium oxide is lower. The main minerals are plagioclase (feldspar-metamorphic stone), olivine, rich pyroxene and titanium pyroxene, olivine and pyroxene between the reaction side, without purple pyroxene, and contains potassium feldspar, Crooked feldspar and white garnet, nepheline, sodium and other feldspar stone. Mainly distributed in the mainland and marine volcanic island. In the Asian Pacific Rim Basin, alkaline basalts are located near the continental side. In addition, in the Hawaiian Islands to contain the actual mineral olivine greater than 5%, the standard mineral nepheline is less than 5% of the basalt is also called alkaline basalt. Alkaline olive basaltic rocks are also referred to as alkaline basalt rocks.

- Q: The world's most famous columnar basalt

- The dense lava flow is cooled, contracted at a vertical angle, and decomposed in the direction perpendicular to the lava flow direction to form a distinctive geometry, which is the formation of a columnar basalt, which has a regular hexagonal shape, Even close to the artificially manufactured specifications.The world's most famous pillar basaltic structure includes: the Irish coast "Giant's Causeway" (Giant's Causeway), the largest and widely recognized by the United States Wyoming's "Devil Tower" (Devil's Tower).

- Q: The difference between basalt and limestone

- Basalt is the main component of silica, aluminum oxide, iron oxide, calcium oxide, magnesium oxide (and a small amount of potassium oxide, sodium oxide), which contains the largest silica, accounting for about 45 percent to About fifty Basalts are mostly black, dark brown or dark green, and because of their dense texture, the proportion of granite, limestone, sandstone and shale is heavy, but some basalts are much more , Even in the water can float up.Therefore, this kind of porous body light basalt, called "pumice".

- Q: What is tholetic basalt?

- Basalt from the main element of the angle of the points can be divided into two types, one is pull-tabreived basalt, one is alkaline basalt. The former silica content is relatively high, while the alkalinity is low; the latter is the opposite. From the structural point of view, pull basalt is the main component of the oceanic crust and alkaline basalt is the main component of the ocean island seamounts. From the source area, the source region of the basaltic basalts is shallow and the basal basalts are deep. But in the wild generally can not directly from the appearance of these two rocks.

- Q: Why basalts have columnar joints?

- From your question, you are a geography of the people. I also! First is not joint, but cleavage. Cleavage and molecular structure and grain size have a major relationship. Basalt is a magmatic rock in the rock, to reach the surface after the rapid cooling, are fine particle structure, grain diameter 0.1-1mm. In the role of force is easy to diverge to the surrounding, and showed columnar cleavage.

- Q: What is the characteristic of basalt?

- Basalts are very durable, jointed, and the joints are mostly hexagonal (in the basalt lava flow, the vertical condensation of rocks often develop into regular hexagonal columnar joints) and brittle, and thus difficult to take large pieces of stone, As the pores and almond structure common, although the basaltic surface is widely distributed, but can be made no small stone.

- Q: What is the use of basalt?

- Basalts are mostly black, dark brown or dark green, and because of their dense texture, the proportion of granite, limestone, sandstone and shale is heavy, but some basalts are much more , Even in the water can float.Therefore, this kind of porous body light basalt, called "pumice." Some artists, according to pumice porous and wrinkled, leak characteristics. Used to build the garden of rockery, or carved into small and exquisite Bonsai.

- Q: Basalt stone is corroded steel

- Basalt is also a high-quality traffic construction stone, especially construction and construction of roads, railways, port terminals, airport runways and other projects in one of the best building materials, which has a high compressive strength, crushing value is low, Low water absorption, weak conductivity, strong corrosion resistance, asphalt adhesion and other characteristics, the international recognition is the development of rail transport and road transport the best cornerstone. ?????? At the same time basalt excellent compression resistance conditions, and good wear resistance, low water absorption reasons, it is also very good building decoration materials, can be widely used in indoor and outdoor decoration, and mainly used for outdoor stone, its natural color , Can be very good and Zhou landscape coordination, very suitable for outdoor landscape construction, especially the best choice for ground floor stone. But as mentioned earlier, basalt easy to form hexagonal columnar joints, and easy to brittle, so the stone blocks are generally not large, the lack of aniseed, not easy to produce large-size plate.

- Q: Granite, limestone and basalt from the color and appearance how to distinguish

- Building stone material is: limestone, sandstone, gneiss, quartzite, granite, syenite, diorite, and so on. Can use granite General black is basalt and other igneous rocks, more difficult to break when the stone used

Send your message to us

Reinforcement Fabric Made from Basalt Fiber for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords