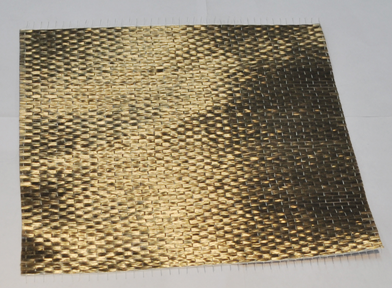

High Quality Basalt Fiber Fireproof Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description:

Basalt fiber fireproof cloth is a single filament fineness of the 9-11μm of the basalt fiber yarn woven, twill and satin were cloth. Fireproof cloth through high temperature, non-toxic, smoke-free flame-retardant coating, the liner can be used to avoid the fire and flame retardant protective clothing, thermal insulation material, fire curtain is the best material. Because it has not flammable, flame-retardant smoke-free, high temperature, no toxic gas emissions, good insulation, no melting or dripping, high strength, non shrink the advantages of the phenomenon, therefore, fire prevention materials market will be the aramid fiber cloth (Kavlar, Nomex, Teflon, etc.) a strong competitor.

1) suitable for shipbuilding, steel and electrical maintenance of large-site welding, gas cutting of protective equipment, fireproof cloth wall; specifications: Applications

Applications

2) textile, chemical, metallurgy, theaters, military, fire and protective equipment such as ventilation, fire helmet, neck care fabric;

3) non-combustible material for the basalt fiber fireproof cloth, flame at 1000 ℃ under, no distortion, no burst, can be wet, steam, smoke, chemical gases with the environment play a protective role under. Also applies to the fire service to avoid fire, fire curtain, fire blanket, fire package.

| Product Code | Density (roots / cm) | Fracture strength (N/2.5cm) | Organization | The maximum temperature (℃) | ||

| Warp | Weft | Warp | Weft | |||

| TX640 | 20±1 | 18±1 | 3500 | 3000 | Double weft twill, satin | 450 |

| TX550 | 20±1 | 14±1 | 3500 | 3000 | Twill, satin | 450 |

| TX480 | 20±1 | 13±1 | 3000 | 2700 | Twill, satin | 450 |

| TX480 | 20±1 | 14±1 | 3000 | 2500 | Twill, satin | 450 |

| TX430 | 20±1 | 14±1 | 2700 | 2500 | Twill, satin | 450 |

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What is sheaf packing in waste plastic industry?

- 1, It is sheaf packing, but not the debris or particles packed space bags. 2, White cast is the color of fracture part and it includes blue, white and slant blue. The white cast should be transparent or white.

- Q: What's the difference between g;ass reinforeced plastics and ordinary glass?

- There are no difference and there are all glass fiber reinforced plastic!

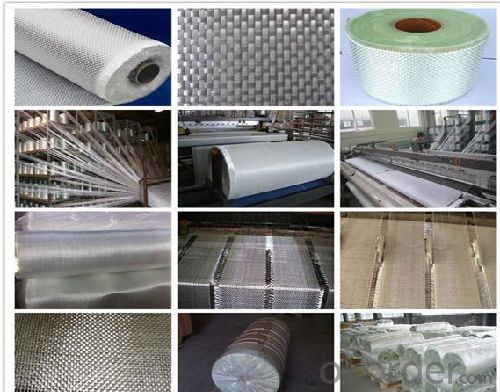

- Q: How many specifications of glass fiber?

- According to fiber diameter, there are many varieties and specifications and spun yarn is used for industry and electron in term of application. There are many specifications including E series, G series, D series and H series.

- Q: The difference between EPS and GRC, advantages and disadvantages, construction technology, key points, the scope of application.

- Fissure is easy to leak water in the cold temperature. Flat connector does not absorb water with a little amount of coating and short production cycle (about 7-12 days). GRC decorative elements is heavy. Due to its shorter installation, it does not require very specialized workers. There is no problem under the temperature of plus or minus 50 degrees Celsius. It has excellent waterproof performance. It has pore and is not easy to chap, but it is easy to deal with and carry with good toughness. If you want to refit it, you need to do some waterproofing work. The connector can absorb water and the material used for producing is belongs to stiffness material with less crack. Finished products features with lightweight, crisp, poor uniformity. High-level job is difficult to process without leakage. Cracking phenomenon is serious and can be cut. Hot bridge is different to control with protective layer features with weathering resistance. Its weight account for 10% of the traditional non light components. Large deformation period is slow. It can be bended moderately. It features with freezing and?thawing resistance and little deformation. It is easy to install and crack so that it needs to be trimmed. It is easy to be linear deformation.

- Q: What parameters should be provided for the customs clearance of the glass fiber?

- After knowing specific custom code, you can check the elements for declaration at the custums net. The elements for declarationare mainly includes 1 material (glass fiber) 2 kinds (comb). However, we can not determine the custom code of glass fiber which proprably includes in the 7019 part.

- Q: Fiber has the difference between twist and twist

- The roving is divided into direct roving (also called direct yarn) and plied rovingDirect roving is defined as: parallel filaments and twisting and formed cluster body, no direct roving raw silk production process is relatively simple, products made of high strength glass steel products, can be directly applied to the winding and pultrusion process, can be directly used for cloth (i.e. roving fabric, commonly known as Plaid), therefore is widely used.

- Q: Does centrifugal glass wool is made from glass fiber

- No, it doesn't. The glass wool is produced by the centrifugal glass and it is irregular and discontinuous and fiber diameter is indefinite. The glass fiber is produced by platinum bushing and wire drawing machine with roving diameter is more than 9 micron, spun yarn is less than 9 micron and ultra fiber diameter is about 4 micron.

- Q: HS code for alkali-free glass fiber yarn

- The HS encoding the alkali-free glass fiber roving yarn is 70191200 and chopped yarn, spinning and Chinese HS EU tariff as follows, S and Z. Spun yarn is a spinning twist E-glass fiber. My question is whether it is yarn or spun yarn. If it is yarn, it would be twistless.

- Q: What can glass fiber do?

- Building for external wall insulation layer, glass fiber clothes are used in the glass fiber industry. The main effect is to increase the strength.

Send your message to us

High Quality Basalt Fiber Fireproof Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords