Silica Brick - Fireproof High Temperature Refractory Fire Clay Aluminum Silicate Bricks for Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Silicate bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C and high refractoriness under load, It mainly used at high temperature area include arch and upside of hot stove and upside of checker. Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Application:

1 Building materials for blast furnace

2 Building materials for hot-blast stove

3 Building materials for coke oven

4 Building materials for steel making furnace

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Strict Quality Control. Meet clients' quality requirement.

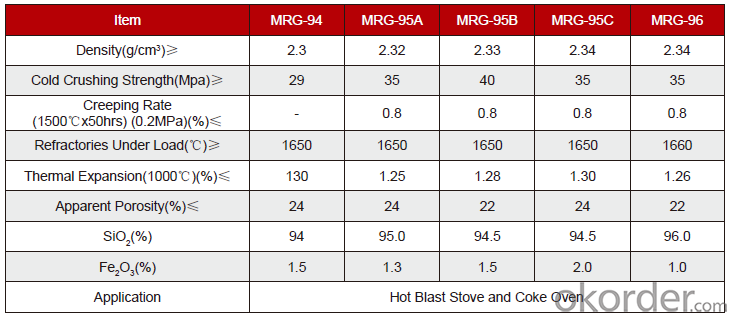

Typical features:

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: Which material is good for furnace refractory?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: What are the main constituents of refractory bricks?

- Clay brick and clay brick are mainly composed of mullite (25% ~ 50%), glass phase (25% ~ 60%) and square quartz and quartz (up to 30%). Usually with hard clay as raw material, pre calcined mature material, and then with soft clay, semi dry or plastic molding, the temperature at 1300~1400 C fired clay brick products. Can also be added a small amount of water, glass, cement and other binders to make non burning products and amorphous materials. It is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: Why in the production of the brick to detect the volume density

- Product quality control of silica brick.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

Send your message to us

Silica Brick - Fireproof High Temperature Refractory Fire Clay Aluminum Silicate Bricks for Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords