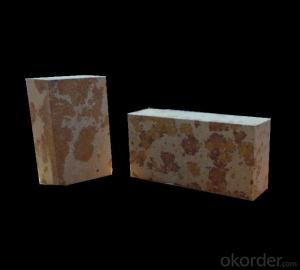

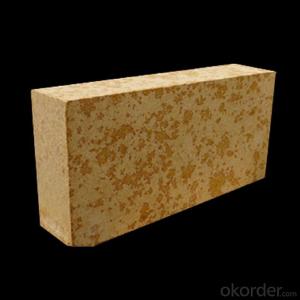

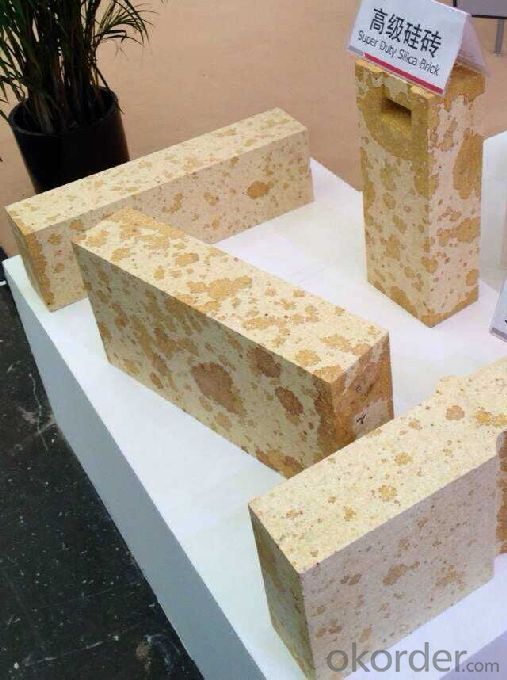

Raw Materials for Refractory Silica Brick Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Refractory is a kind of non-metallic material with refractoriness not less than 1580 ℃, which has better thermal shock resistance and chemical erosion resistance, low heat conductivity coefficient and low expansion coefficient. Refractoriness is the centigrade?temperature of refractory cone specimen wiyhout any load resisting high temperatures without melting down Refractory is widely used in industries like metallurgy, chemical, petroleum, machinery manufacturing, silicates, power, etc., which is mostly used in the metallurgical industry, accounting for 50% to 60% of total output.

- Q: How to understand qualitative and qualitative refractory materials?

- Such as amorphous refractory castable, referred to as bulk loading, cast material, ramming material, refractory clay etc., utensils and other special products. Amorphous refractory material products, refractory heat insulating bricks and experimental and industrial crucible, spraying materials, such as burning bricks, electric melting brick, turn it into required shape and process heat treatment in where it is used.

- Q: How can refractory materials be divided?

- There are many criteria for the classification of refractories.Just referring to a book about refractory.

- Q: which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q: What are fireproofing materials?

- Plants often use the fireproof sealing material with steel structures without much modification. All the panels that meet the first-order fire protection requirements can be fireproofing materials. Like gypsum boards, aluminum sheets and so on. . Coatings are usually those with fine powder, high density and good sealing. Hardeners mainly depends on specific requirements. .

- Q: what is the fireproofing material of engine room? who knows it ?

- 1. The new type fire?retardant?coating in fire retardant coating, the expanded vermiculite, expanded perlite heat insulation material and cenosphere adiabatic powder, etc. These inorganic component, is a major part of the thick coating type of fireproof coating, and they also are the major factor affecting the level of performance of fireproof coatings. The fireproofing thermal insulation properties of fireproof coating, is mainly determined by the fire back surface temperature of this factor, but also related to the fire endurance. If it reaches the same temperature for a longer time, it shows that it's fireproof thermal insulation is better, and the fire endurance therefore is higher. 2. The new fireproof board new fireproof board now is welcomed by the people and the important factor is its environmental protection, and with the increasing high-rise buildings, the fire protection requirements and strength requirements are also rising, it is a big challenge for the performance and standard of the fireproof board.. Now fireproof board is mainly used siliceous material or calcareous materials, and then mixed with the fiber material, lightweight aggregate, adhesives and chemical additives, it is not only be fireproofing, but also improve their thermal insulation performance, and light weight, good carrying capacity, good durability, no aging problem, more importantly, it is good in environmental protection.

- Q: Is aluminium oxide refractory material?

- Calcination aluminium oxide is refractory material of fine performance made from pure aluminium oxide through high-temperature calcination. It can be made into coarse-grained material, fine-grained material, fine powder and micro powder, which can be made into pure jade burnt products. For example, corundum brick, lightweight corundum bricks. It can also be made into a variety of unburning products together with other materials, such as carbonaceous materials. For example, aluminum carbon and aluminium zirconium carbonaceous materials. As for the production of unshaped refractory material, there are more species. It can be corundum, rubing grain, corundum spinel and can also be added into other materials to improve specific performance. It isn't limited to high-alumina castable refractory and it can be castable refractory, ramming?mass, impressionable plastic material, gunning mix and refractory mortar.

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: What are the advantages of refractory material?

- Jingute WHL type, GDS type

Send your message to us

Raw Materials for Refractory Silica Brick Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords