Glass Wool Refractory Material Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

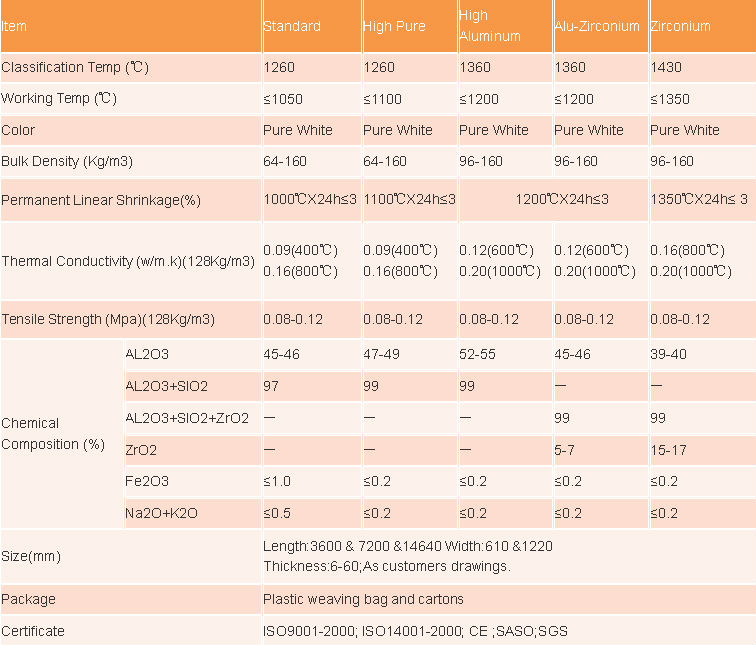

Technical Data of Ceramic Fiber Blanket

Remarks: The data above is for reference. The Max. temperature depends on the using conditions.

Product Description:

CeramicLooseFiberis made by the melted raw materials at high temperature through resistance furnace, before being blown or spun into fiber. As a neutral and acidic material, except reaction with the strong acid-alkali,refractoryceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity. Ceramic fiber is of smaller density, more than 75% lighter than insulation brick lining or 90% -95% lighter than lightweight castable lining, with thermal conductivity co-efficient to be 1/8 of the lightweight clay brick or 1/10 of lightweight heat-resistant lining (castable), and heat capacity to be 1/10 of both lightweight insulation lining and lightweight castable lining, thus to greatly lower energy loss and deliver significant energy-saving regenerative effects. Meanwhile, the ceramic fiber features a simple construction with no need of baking oven, shortened construction cycle and easy installation.

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space.

- Q: Rock wool board and glass?wool?board, which is more harmful to human body?

- Many countries have banned such hazardous substances. The security of glass wool board is high for the asbestos fibers can cause asbestosis, pleural mesothelioma and other diseases.

- Q: How to conduct thermal insulation construction of external wall glass wool?

- I would like to give a brief introduction to the usage of glass wool as the thermal insulation for equipment. 1, Cleaning dust on the surface of equipment. 2, Using adhesive to glue the iron sheet of insulation nails (iron sheet of one square centimeter will be fed in the middle with a slightly harder iron wire of about 8 centimeters) on the surface of the device. Distribution density depends on the weight of glass wool. If insulated cotton is 1 m * 0.5 m, it merely needs to glue seven to eight insulation nails. When glue of iron sheet finished, the device is like a hedgehog. 3. Once insulation nails sticked firmly, it needs to affix to glass wool, fixing it with a piece of spare iron sheet with a hole in the middle of it (it is round and is a set with insulation nails), and then bend the redundant part of iron wire. Wish it will help you. Thank you!

- Q: Does anyone know about the general unit weight of glass cotton color steel?plate?

- 7.85 tons / cubic meter. The unit weight is also known as weight density. There are two kinds of understandings about it: 1. It refers to the weight of the object in unit volume, is commonly used to refer to the weight of a cube in engineering, such as the weight of soil mass per unit volume. 2. It shows the gravity property of object affected by gravity, for homogeneous fluid it refers to the gravity per unit volume. Its unit is: N / cubic meter.

- Q: During the construction of steel structure, should the aluminum foil of glass wool be directed indoors or outdoors? Why?

- When the steel structure is constructed, aluminum foil of glass wool should point toward the indoor.

- Q: What are the specific differences between glass wool board and glass fiber board?

- Thus, the full name of glass wool is glass fiber wool: There are two kinds of glass fibers from the uses of fiber glass. The fiber used to weave is the continuous fiber, continuous fiber and staple fiber, and the fiber used to make cotton is staple fiber, glass wool board is equivalent to glass fiber board. You are reminded by the Shouchuang Decoration

- Q: Are there any differences between rubber and plastic thermal insulation materials and glass wool thermal insulation materials? Which one is better, please tell me more about it.

- Rubber and plastic materials have a good thermal insulation performance(thermal insulation equipment medium has a lower temperature), the fire?rating of glass wool is high(insulation equipment medium has a low temperature), rubber and plastic materials are a little bit more expensive than glass wool materials.

- Q: What is the difference between glass wool and rock wool insulation board insulation board ?

- glass wool and rock wool insulation board differs in their performance. Glass wool has lighter unit weight, lower shot content and thermal conductivity, longer durable years, higher fiber tensile strength. And the maximum temperature that the rockwool can endure is about 600 degrees Celsius while the glass wool is only about 260 degrees Celsius. if it is used for general building insulation or low temperature pipe, you can use glass wool, if it is used at parts where the temperature is about 500 degrees Celsius. rockwool is better. I hope my answers above are helpful to you and your ideal anwers.

- Q: What is the main use of glass wool insulation materials?

- Uses of glass wool insulation material, glass wool: The main raw materials are glass, class A fireproof rating, thermal conductivity coefficient 0.037, shrinking temperature of 270 degrees, use: Good cold insualtion property.

- Q: Glass core material of ultra-fine glass wool

- Glass core material is an important component of VIP, playing an significant role on the heat conductivity coefficient of vacuum insulated panel. Vacuumized core material has certain intensity, which can play a framework supporting role. And the fiber distribution of core material determines the VIP adiabatic degree. Thus, the more uniform the fiber distribution of core material, The lower its heat conductivity coefficient and the better the insulating property.

- Q: What is the construction technology of glass wool felt aluminium expanded sheet sound-absorbent wall?

- 1, Technological process: Dry laying a layer of asphalt felt →install wood keel → install gypsum board → paste glass wool felt → pave and nail a layer of glass fiber cloth → install aluminium expanded sheets → fix aluminium expanded sheets. 2, Operating points of the construction method. a, Embedded anticorrosion wood bricks: During masonry construction, laying bricks while pre-casting anticorrosion wood bricks (40 × 60 × 60), and the horizontal distance is 400 to 500 with the vertical distance of 400.

Send your message to us

Glass Wool Refractory Material Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords