Raw Materials for Refractory:Refractory Grain SiC 98.5 SiC Sands 98/92/90

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grain SiC 98.5 SIC Sands 98/92/90

1.Structure of Silicon Carbide Description

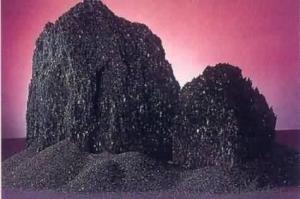

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

1. corrosion resistance, high strength, high hardness,

2.good wear-resisting performance,resist to shock

3.stable chemical performance, high thermal conductivity, high resistant temperature

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: How can refractory material of the electric furnace be used for longer.

- I do not know if you are referring to super high power arc furnace for steelmaking, if you are, I have a easy solution for I have been doing this work.

- Q: What is the requirement of refractory concrete for raw materials? What is the main principle of commercial mixing station?

- There are many kinds of raw materials used, three, two aluminum oxide is one of the most commonly used raw materials, as well as alumina, hollow ball, Magnesium Oxide, zircon, etc., or the specific design temperature and the use of parts.

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on.

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: What are the filling refractories in door leaf of class A fire resistant door?

- That depends. Most are perlite fireproof?panel, MC composite material and other fireproofing materials, vermiculite fireproof board, while some are foam door filling board.

- Q: What refractory material does cupola lining use?

- In order to improve the service life of the lower wall and the bottom leather, dense and high alumina brick can be used for masonry. The front furnace is composed of the bottom, the wall and the top. The top of the furnace is vaulted or hanging flat roof. The front furnace body is usually made of clay brick and high alumina brick, and the bottom work floor is rammed with ramming material. The material is the same as that of cupola furnace. The bridge and the front guard taphole, slag hole and other parts due to erosion by high temperature molten iron and slag erosion, lower service life, frequent repairs. Large blast furnace adopts hot blast or oxygen enriched blast, which has higher temperature and higher production capacity... The damage is faster, and it is hard to maintain production by using clay brick or high alumina brick. Should be used aluminum, carbon or corundum refractory silicon carbide castables pouring or tamping, so that the integrity of good, high strength, corrosion resistance, and therefore significantly improved service life, generally up to one year or so. Refractory materials, including chimneys and spark traps, are used in other parts of the cupola. The chimney and the cupola shaft directly connected with the shell made of steel plate, lined with ordinary clay brick, can also be used ordinary refractory castable pouring. The chimney is provided with a furnace heat exchanger, which can preheat the air to 300~500 DEG C, and the spark collector is used for catching the hot coke and dust particles brought out in the flue gas. The chimney at the top of the reflector (cover) by plate welding, can also be used to cast iron, its lining refractory coating or spraying paint.

- Q: How is the performance of refractory materials?

- It is a little difficult to answer. There are some requirement for refractory materials, such as fire resistance, softness, creep, thermal shock, abrasive resistance. Besides, requirements for construction performance include: Liquidity, plasticity and other linear change rate, volume density, strength (including high temperature) and all other important indicators must be tested the same conditions with the use of test conditions and test items like body density, strength, line changes in the basic project

- Q: What's the frequently used refractory material?

- Refractory material is generally used in industrial departments like metallurgy, glass, cement, ceramics, machinery, hot working, petrochemical industry, power and national defense. Frequently used common refractory: silica?brick, semi-silica brick, clay brick, high alumina brick, magnesia brick, etc. Frequently used special refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, calcium oxide, chromium hemitrioxide, alumina, magnesium oxide, etc. Frequently used fireclay insulating refractory: diatomite product, asbestos product, insulation?board, etc. Frequently used unshaped refractory: ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, refractory coating, lightweight refractory?castables, etc.

- Q: What does refractory mean?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: What are the fireproofing materials of the external wall included?

- According to the external wall thermal insulation materials, the external insulation materials is in general divided into Class A and Class B. The A class is non-combustible material. The B class is combustible materials. The fire disasters of the CCTV building and Shenyang hotel are both caused by the B level materials. Generally, the A level material will be used, and some prices are even cheaper than the B-grade material. A level is roughly divided into thermal?mortar, phenolic foam Board, rock wool board, foam cement board, and so on. I hope my answer will help you!

Send your message to us

Raw Materials for Refractory:Refractory Grain SiC 98.5 SiC Sands 98/92/90

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords