Raw Materials for Refractory:Silicon Carbide 90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide90/Recrystallized Silicon Carbide/SIC

1.Structure of Silicon Carbide Description

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

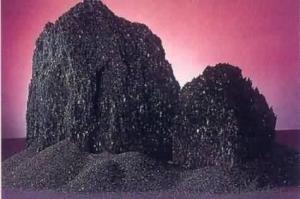

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Grade | SiC | F.C | Fe2O3 |

≥ | ≤ | ||

SiC98.5 | 98.5 | 0.20 | 0.60 |

SiC98 | 98 | 0.30 | 0.80 |

SiC97 | 97 | 0.30 | 1.00 |

SiC95 | 95 | 0.40 | 1.00 |

SiC90 | 90 | 0.60 | 1.20 |

SiC70 | 70 | 3 | / |

SiC65 | 65 | 5 | / |

SiC60 | 60 | 10 | / |

SiC55 | 55 | 10 | / |

SiC50 | 50 | 10 | / |

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: what's the application of fireproofing abs materials?

- ABS alloy shell, a toy of child, low load bearing, refrigerator lining, it can be processed into various wear-resisting sheets, plates,and has good electrical performance, it can be used as electronic components or auto parts, all kinds of insulation materials, it's easy to machining on the surface, so it can be made into designated special products (such as electroplate), and easy coloring,

- Q: What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- Fire endurance (h): Under the condition of standard fire resistance test, the time when the building components, accessories, or structure is subjected to fire to the time when they loose stability, integrality or thermal insulation is called fire endurance which is showed in time. Steel is the kind of building material that is nonflammable with many properties of seismic resistance and bending resistance. In practical applications, steel can improve the load capacity of buildings in a relative way, meet the needs of buildings design, beauty and mould, and it can also avoid the defects of poor flexibility and tensile strength of buliding materials like concrete. Therefore, steel is quite popular in the construction industry, and it is widely used in single-story or multi-storey skyscrapers, plants, warehouses, waiting rooms and airport terminals, etc. However, as a kind of building material, it has some unavoidable defects in fire prevention. That is its mechanical properties like yield point, tensil strength and elasticity modulus will decrease dramatically with the rise of the temperature.

- Q: What kind of materials can be tested their electrical resistivity in the current refractory industry?

- fused cast bricks, fused zirconia corundum blocks, corundum, high zirconium

- Q: What are the requirements when producing fireproof materials by kaolin?

- Kaolin refractories in fact play a role in two aspects, one is to improve the refractoriness, the second is to improve plasticity of the the refractory . Aluminum content the higher the better, of course, but kaolin is not the only material to improve the content of aluminum, using materials that contain higher content of aluminum such as the bauxite chamotte. So the content of kaolin aluminum does not have to be too high. over 38% is fine. viscosity is important and strong viscidityis better without having to add bentonite. Refractoriness above 1400 degrees is enough.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

- Q: What is fire retardant coating mainly used for?

- The functions of refractory coating are as follows: 1. Non-intumescent fire retardant coating is mainly used for the fireproofing of wood, fiber board and other materials, and it is used in the surfaces of wood truss, roof, doors, windows and etc. Second, the intumescent fire retardant coating can be divided into non-toxic intumescent fire retardant coating, expansible fire retardant coating emulsions, solvent-based fire retardant coating. 3. Non-toxic intumescent fire retardant coating can be used to protect cables, polyethylene pipes and insulation board. 4, The expansible fire retardant coating emulsion and solvent-based fire retardant coating can be used for fireproofing of buildings, electricity power, and cables. 5. New fire retardant coating: Transparent fire retardant coating, water-soluble intumescent fire retardant coating, fireproof emulsion paint, polyvinyl acetate emulsion fire retardant paint, water-soluble intumescent fire retardant paint drying at room temperature, fire insulation coating polyolefin fire retardant coating, modified high chloropolyethylene fire retardant paint, chlorinated rubber fire retardant coating, firewall coating, intumescent coatings, wire and cable fire retardant paint, new fire retardant coating, casting fire retardant coating and so on.

- Q: Classification of porosities in refractories and their effects on properties

- The pores in refractory include open pores, through pores and closed pores.

- Q: Who knows how many poured refactory material are there?

- Pouring refractory material can be classified into the followings according to the body density: Heavy (> 2.0g\cm3), medium heavy (1.0-2.0g\cm3), light (0.4-1.0g\cm3); by binding agent: Combination of hydration, chemical binding, condensation, hydration and condensation: Clay, high alumina, silica, magnesia, alumina magnesia, magnesium and chromium, magnesium zirconium, silicon carbide etc.. Clay brick, high alumina brick, bead brick, silica brick, light mullite, alumina hollow spherical brick, oxidation zirconium hollow spherical brick, corundum brick, magnesia brick, magnesia brick, magnesia alumina spinel brick, magnesia chrome brick and so on

Send your message to us

Raw Materials for Refractory:Silicon Carbide 90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords