Fireclay Brick - Refractory Checker Brick for Hot Blast Furnace and Coke Oven

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Information:

Fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Feature:

Low thermal conductivity;

High refractoriness;

High mechanical strength;

Excellent thermal shock resistance;

Application:

Fireclay bricks are commonly applied in blast furnace, hot blast furnace, coke oven, glass furnace, etc.

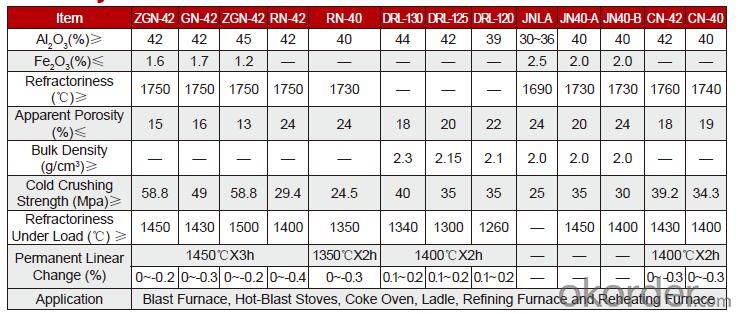

Technical Data:

Company Information:

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

One Stop Service

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: how much fireclay is needed for 10000 refractory bricks?

- The amount of mud used for T-3 refractory brick is 0.3KG. if the tiler is skillful, the furnace should have joint of 2mm.

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: What types of refractory bricks are divided into?

- Chimney and flue are places that high temperature gas of sulfur gathers, it should use acid material. Refractory material is divided into three major parts: acid, neutral and alkaline.

- Q: how much is the content of the high alumina of refractory brick?

- linear?change?on?reheating is small and Slag resistance is good, matte smelting, good thermal shock resistance used refractory materials should be resistant to high temperature: In front of the furnace, the temperature can reach 1800, copper blowing. The maximum temperature in the smelting furnace area is on the top, pyro-refining and electrorefining, magnesia chrome brick, magnesia chrome castable, magnesia alumina brick. The commonly used refractory materials is direct-bonded?magnesia-chrome?bricks, which has large volume density. manufacturing technique of copper smelting consists of five parts, Clay brick

- Q: Why limit sintering brick first and develop new wall material?

- The sintering brick is not fit for the national energy saving policy. Indeed, to do a good job of energy saving and emission reduction, and protect our living environment, the relevant departments under the state issued a ban on the construction of the construction industry, prohibit the use of ordinary clay sintering.

- Q: should clay or refractory cement be used to lay refractory bricks?

- structure strength of this brick lining is not good, apply some refractory mud, only use some virgin clay and corundum, many of the traditional approaches are very simple, mullite and carbon slurry, the specific products are selected according to the selected material and water glass or organic binder. binding agent can choose phosphate, silica and high alumina, clay is one part of the refractory clay, there are many kinds of refractory slurry according to the material, clay-based mud does use refractory cement and corrosion resistance is low

- Q: Why is the brick instead of solid clay brick

- Shale is a sedimentary rock weathering hard substance, which is relatively hard, mainly from clay minerals and small clay particles into the pressure, cementation, weathering after the formation of hard substances, such substances are relatively hard.

- Q: What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- High alumina brick and hanging brick are ok.

- Q: What material does tile tunnel kiln use to replace the refractory brick to have better insulation effect and save the maintenance and prolong the service life?

- The price is high, but the the service life is not longer than the clay brick, some use high aluminia brick. Currently, there are no refractory products that can replace refractory bricks. The effect is good of choosing fireclay brick with high strength dense, low porosity clay brick. We have maken several lines of refractory bricks. Actually, if you choose good refractory brick, the service life will be very long. The kiln temperature is not high.

Send your message to us

Fireclay Brick - Refractory Checker Brick for Hot Blast Furnace and Coke Oven

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords