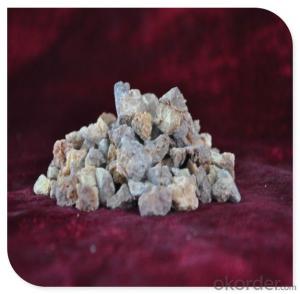

Raw Materials for Refractory:DBM Dead Burnt Magnesite 97%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory DBM Dead Burnt Magnesite 97%

Specifications

1.Feed additive

2.Fertilizer for Soil Remediation

3.Water Treatment and paper

4.Making Portland Cement

5.For abrasive wheel

Kind | Brand | Chemical Composition % | Grain size (mm) | ||||||

MgO Min. | SiO2 Max. | CaO Max. | Fe2O3 Max. | B.D Min. | |||||

High-Purity Magnesite Sinter | DBM-96 | 96 | 1.0 | 1.4 | 0.8 | 3.25 | 0~30 | ||

DBM-97B | 97 | 0.7 | 1.4 | 0.8 | 3.25 | ||||

DBM-97A | 97.5 | 0.6 | 1.2 | 0.7 | 3.30 | ||||

DBM-98 | 97.7 | 0.5 | 1.2 | 0.5 | 3.30 | ||||

Our Lab

Our Service:

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: For refractory, what is critical particle size? Thank you.

- For example, in refractory technology, if there is an express of equal to or lower than 0.008mm, 0.008 refers to critical particle size. The main criterion for judging performance of three major continuous casting is the major three normal temperature indexes (compressive strength and anti bending strength at normal temperature, apparent porosity and bulk density). Does this criterion have any defect? How to do multiple test if high-temperature index introduced? Carbon bond is one of the three major castings. How does it form? What do you think of it? Hope someone explains it for me. Thanks a lot!

- Q: The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

- Q: How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- The standards of fireproof and thermal insulation material. 1. the height of buildings is greater than or equal to 100 m, the combustion performance of thermal insulation materials should be A-level; 2. the height of buildings is greater than or equal 60 m but less than 100 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in each floor; 3. the height of buildings is greater than or equal to 24 m but less than 60 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in every two floors; 4, the height of buildings is less than 24 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in every three floors.

- Q: Refractory factory grinding brick dust harmful to the body?

- Inhalation of this dust can affect people's respiratory tract for a long time

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- Fire rating of the best aluminium-plastic?panel in the current market is B1 class, and its grade classifications can refer to the national standard. I have examined factories and tested the fireproof effect of the fire-proof plate myself by burning it, and I have found that the fire-proof plate of Jinwei Aluminium-plastic?Panel in Linyi is really good in quality and fire prevention. In other words, from the single point of fire rating, the corresponding fire rating of the called fireproof aluminum (plastic) composite panel should be at least B class, and for A2 class fireproof aluminum composite panel, its core material currently doesn't include plastic element, so it's called aluminum composite panel which is of inorganic core material. If the ordinary aluminum-plastic panel is classified according to the fire-proof building material, it will belong to that of lower level. For aluminum-pastic panel used in business premises, it is required to reach the grade of flame retardant material or above this in fire prevention. It is expressly stipulated that its fire rating should be A2 class in public places.

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- Refractories in this industry, Luoyang Hua Heng is the first to bear, and their services are thoughtful, and the quality is still very good!Wish you success!

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- According to the duration of fire resistance, fireproof doors can be divided into three levels, namely level A,B,C. And accordingly, the duration of fire resistance of them should not lower than 1.20h, 0.90h and 0.60h. Fireproof door, a door that can meet the requirements of fire resistance stability, fireproof door integrity and thermal insulation at a certain time, is a fireproof separator which is located in fireproof partition, emergency staircase and vertical silo. Apart from functioning as a common door, a fireproof can also prevent the spread of fire and smoke in a certain period to make sure that people are safely evacuated.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named according to its structure, and fire-resistant busway is named after its uses. Compact busway especially refers to busway which is closely laminated between phases and between phase and shell, and use thin insulating material to achieve the insulation result. Suitable for power supply system of alternating current three-phase four-wire, three-phase five-wire system, frequency of 50 ~ 60Hz, rated voltage up to 690V, rated operational current of 250 ~ 5000A, as auxiliary equipment for mining, enterprises and high-rise buildings, and especially suitable for the transformation of workshop and old enterprises. Fire-resistant busway is composed of shell coated with fire retardant paint, bus line wrapped with fire-resistant mica tape and bracket made by refractory insulating material. Bracket has a plurality of grooves where inbedding the bus line and fixed it. There is a busway connecting box at one end of the busway and there is a bus line splitter box in the busway. Fire-resistant busway has excellent insulation properties, which can not only be used continuously in a normal environment, but also can be used in the fire environment continuously for more than one hour, suitable for high-rise buildings and important facilities.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- The fire-resisting time of class B fire proof door is 1h and thickness of door can't be lower than 45mm.

Send your message to us

Raw Materials for Refractory:DBM Dead Burnt Magnesite 97%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords