High Alumina Refractory Brick for Steel, Cement, and Glass Making Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

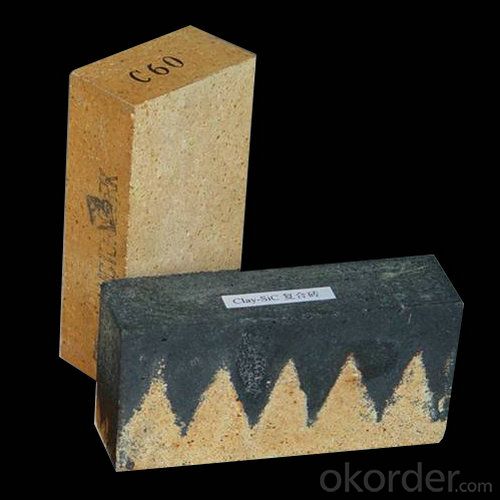

Description of Refractory Brick

Certified by ISO 9001:2008 Certificate, Refractory Brick Used for Steel Cement Glass Making Furnaces is made by the most innovative technology in China.

Refractory Brick, using high pure mullite as raw material, is made by adding alumina powder according to different type and then sintering in high temperature. JM insulating brick is the new energy saving material for insulation.

Features of Refractory Brick

(1) Excellent refractoriness

(2) Excellent chemical stability and thermal stability

(3) Low thermal conductivity, low thermal capacity

(4) Resist to external mechanical forces

(5) Able to withstand any thermal shock

(6) Generate no gaps between modules

Specifications for Refractory Brick

| Product Name | Refractory Brick Used for Steel Cement Glass Making Furnaces |

| Standard Size | 230*114*65mm |

| Application | ethylene cracking furnace, synthetic ammonia conversion furnace, tubular heater, coal-gas generator and other of petrochemical industrial furnaces |

| Characteristics | low density,low conductivity,great resistance to thermal shock, low linear shrinkage, high contain of mullite crystal,accurate in demension |

| Product Range | Including JM23,JM26,JM28,JM30,JM32 |

| payment terms | T/T , L/C acceptable |

| Packing | pallet |

Images of Refractory Brick

Applications of Refractory Brick

Common applications :door seals or caulking for ovens, furnaces and boilers, expansion joints, cable or pipe wrapping, high temperature seals or gaskets.

Refractory Brick have been widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, exhaust systems, shipyards, refineries, power plants and chemical plant

FAQ of Refractory Brick

1. Can we visit your factory?

Sure, we warmly welcome you to visit our factory any time. Seeing is believing.

2. After an order is placed, when you will deliver?

10-30days.

3. Does your company accept customization?

We have a strong technical force. Our production methods are unique in that in allows us to be responsive to the needs and specification of our customers. We use a batch method of production, so each technician on the line is responsible for a specific area of expertise. at any point in our production, we can make changes and incorporate the feedback from our clients. We accept OEM service.

4. How is your products quality?

We specialize in fire brick ,our products are superior in quality to any other brand available on the market. These fire brick are gaining popularity because of their fine quality, competitive prices, and our honest dealings.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: What is the price of the first grade high alumina brick?

- Many factories in Xinmi have high alumina bricks, but they must choose a regular factory. Kuwait refractory level high aluminum brick price at around 1600, the quality of double stable supply

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: What are the characteristics of high alumina bricks?

- High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining. High R.U.L, low creep high alumina brick with high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials.

- Q: What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: How to distinguish the good or bad of the high aluminum brick?

- Weigh the weight of the next block. According to the weight standard, a high alumina brick is 3.9 kg in weight, two in high alumina brick, three in high aluminium brick and 4.5 kg in 4.2. The same grade, the same type of high alumina brick, if the weight of a single brick to this standard, but for high quality high alumina brick, otherwise, can not reach such a weight, it shows good quality. If there is a crack, a large piece of broken angle, four sides of inequality, it is for substandard products.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

Send your message to us

High Alumina Refractory Brick for Steel, Cement, and Glass Making Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords