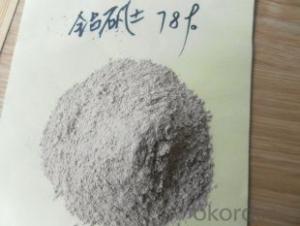

Raw Materials for High Alumina Cement Refractory Cement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1. Rapid-hardening, high strength.

2. High refractoriness, high-temperature service performance.

3. Good resistance to abrasion, high wear resistance.

4. Stable hydrating capacity.

5. Good anti-corrosion performance.

6. High thermal shock stability.

Application:

1. Construction of sulfate corrosion resistance and high temperature proof.

2. Used in rush repairs, leakage stopping , resistance to sulfate attack.

3. Ideal binder for refractories such as refractory concrete, refractory castable, ramming mixing, gunning mixing and manmade marble bricks.

4. Used as ceramic adhesive.

5. Used for sealing coating products and refractory mortar.

6. Used in chemical industry, metallurgical industry, building materials.

High Alumina cement Refractory Cement

Physical and chemical index:

Item | ; Chemical composition % | Al2O3/CaO | The mjor mineral | color | |||

SiO2 | Al2O3 | Fe2O3 | CaO | ||||

Ordinary high alumina cement | 3-9 | 35-45 | 10-17 | 36-40 | 0.85-4.3 | CA,C4AF,C2AS | ash to black |

High alumina cement | 3-6 | 50-65 | 1-3 | 29-40 | 1.2-2.2 | CA,C2AS | pale yellow |

Low calcium high alumina cement | 0-1.4 | 68-80 | 0-1 | 17-27 | 2.8-4.7 | CA,CA2, α- Al2O3 | white |

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- It belongs to material, and after all, more than 60% refractories are used in metallurgical industry. If you insist on classifying it, it belongs to supporting industry of metallurgical industry. Refractory industry itself is independent.

- Q: What characteristics do A grade external wall fireproofing material have?

- 1. Save space and reduce costs; 2. Fireproofing, green and environmental protection; 3. Waterproofing; 4. Sound insulation; 5. Thermal insulation; 6. Install easily and shorten the construction period; 7. High safety performance.

- Q: Who knows the fire resistant level of the rock wool color plate?

- The rock wool color steel rock wool board is used in a area of high ??fire safety requirements. According to "interior decoration of buildings for fire protection design", the color steel rock wool board belongd to level A. Its life is more than 15 years and still can be used when the temperature is up to about 700 ℃, with maximum fireproofing hour of six hours. And the rock wool color plate is a environmentally friendly material, the preferred material in the construction industry .

- Q: What does the function of SiC for refractories?

- Anti-wear! High intensity!

- Q: What are the filling refractories in door leaf of class A fire resistant door?

- Perlite!

- Q: Who can introduce the external wall thermal insulation materials fire rating regulations?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q: What's the frequently used refractory material?

- Refractory material is generally used in industrial departments like metallurgy, glass, cement, ceramics, machinery, hot working, petrochemical industry, power and national defense. Frequently used common refractory: silica?brick, semi-silica brick, clay brick, high alumina brick, magnesia brick, etc. Frequently used special refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, calcium oxide, chromium hemitrioxide, alumina, magnesium oxide, etc. Frequently used fireclay insulating refractory: diatomite product, asbestos product, insulation?board, etc. Frequently used unshaped refractory: ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, refractory coating, lightweight refractory?castables, etc.

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: Can refractory be used as sealing element?

- It can. For example, fiber ceramics can resist high temperature! !

- Q: What's the type of fire proofing thermal insulation materials?

- Hello! Fire proofing thermal insulation material can be classified as inorganic thermal insulation material and composite thermal insulation material. According to the form, it can be divided into fibrous veneer, mineral wool, rock wool, glass wool, aluminum silicate cotton, ceramic fiber, microporous diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete, bubble foam glass, ash, glass, clay, foam concrete, and pasted paste powder polystyrene particles insulation pulp, etc. They are characterized by flame retardancy and fire proofing and thus can be used in buildings with high fire proofing class. Among them, calcium silicate, aluminum silicate and asbestos can also be used for the thermal insulation for heat supply pipelines.

Send your message to us

Raw Materials for High Alumina Cement Refractory Cement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords