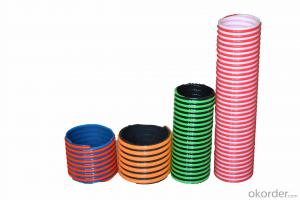

Red Color PVC Suction Hose Plastic Tubes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000ROLL roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Specifications of suction hose:

1) Dimensions: 0.8'' - 6"

2) Material: PVC

3) Color according to client's requirements

Pvc suction hose | Inch | I.D(mm) | O.D(mm) |

5/8 | 14 | 18 | |

3/4 | 19 | 23 | |

2 | 50 | 58 | |

3 | 75 | 83 |

- Q: Are plastic tubes suitable for packaging electronics or electrical components?

- Yes, plastic tubes are suitable for packaging electronics or electrical components. They provide protection against moisture, dust, and other contaminants, ensuring the safety and integrity of the components during storage or transportation. Additionally, plastic tubes can be customized with inserts or padding to provide extra cushioning and prevent damage to the delicate components.

- Q: I need some info about collapsible tubes... so guys pls suggest me some links or some useful points about collapsible tubes like its properties, applications, etc. asap...Thanq Buddies

- Information is below.

- Q: What is the maximum temperature that plastic tubes can withstand?

- The maximum temperature that plastic tubes can withstand varies depending on the type of plastic material used. Generally, most plastic tubes can withstand temperatures up to 150-200 degrees Fahrenheit (65-93 degrees Celsius). However, it is crucial to consult the manufacturer's specifications or testing data for accurate information on the maximum temperature resistance of a specific plastic tube.

- Q: Im looking for plastic tubes like pvc, but clear. about 3ft in length. where can i find it?

- Go to Home Depot or Lowes Home Improvement. They should be well stocked with what you are looking for and the staff are always willing to help customers. Just ask them if they have what you need and they will point you in the right direction.

- Q: Are plastic tubes FDA-approved for food contact?

- Yes, plastic tubes can be FDA-approved for food contact. The FDA sets regulations and guidelines to ensure that food contact materials, including plastic tubes, meet certain safety standards and do not pose a risk to human health.

- Q: can you use rubber tubing to make moonshine?

- You could but real rubber would melt from the heat. Plastic tubing should be avoided because alcohol will leech chemicals from it. Best to use copper, which coverts some bad tasting stuff to better tasting stuff. You could also safely use stainless steel, glass, ceramic. You should avoid brass, unless you know the lead content of the alloy. Cheers.

- Q: Our Kenmore washing machine #110.2970091 recently started leaking water from underneath. When we looked, there was a clear plastic bag/tube attached to a hole on the side of the tub that was leaking.The tube was taped up at the bottom and doesn't look like it's supposed to be there, the water in it looked like it was there awhile. We bought this used so it doesn't have a manual or warranty. If it is an overflow pipe, where is the excess water supposed to go? We have it hooked up to the laundry sink.Thanks

- first element i could do is examine and make useful the drain hose is inserted perfect. whether this is, and you nonetheless have overflow, you ought to have some blockage interior the drain that became no longer observed including your previous washer by using fact it did no longer pump water into the drain as rapid. in case you're mushy doing so, attempt and sparkling the blockage. in case you haven't any longer any thought the thank you to accomplish that, call a plumber.

- Q: i have some rolls of presidential dollar coins. do i need the tubes or can i just leave them in the paper?

- It okorder they are a large coin and stamp supply company. Very few paper type coin rolls are of top quality and archival, most have acid in the paper.

- Q: It needs to be a bit smaller than a pringle tube, min 2mm thickness bout 30cm length maybe 5cm diameter. I need to be able to seal both ends and its got to be sturdy not squashy and preferably shatter proof.Ive seen mailing tubes and poster tubes even baseball bat tubes but there all either too big or come in packs I only need 3...can anyone help? P.s im in the U.K

- I have found you two suppliers of tubes, the second wall thickness isn't what you want but they are complete containers with caps. The first supplier supplies polycarbonate tubing in lengths and this is a very hard wearing clear plastic that you can cut to size with a normal hacksaw and then try and find end caps, or you can ask an engineering shop to turn six end caps for you and cut a groove in to fit an o-ring seal. The first option will be cheaper. Hard wearing isn't cheap.

- Q: Can plastic tubes be used for gardening?

- Yes, plastic tubes can be used for gardening. They can be used as containers for growing plants, as irrigation systems, or for protecting young plants.

Send your message to us

Red Color PVC Suction Hose Plastic Tubes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000ROLL roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords