Recycled Plastic Decking Made in China with CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Recycled Plastic Decking

Item | Recycled Plastic Decking- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

Main Features of Recycled Plastic Decking

1) 30% Grade A Recycled HDPE

2) 60% Professionally treated dry wood fiber

3) 10% Import Chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer,ect. )

New material capped outside

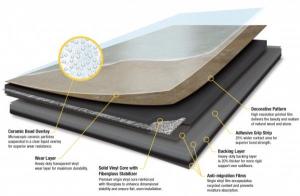

What is co-extrusion high solid co-extrusion wpc portable outdoor flooring ?

Co-extrusion is a new BPC manufacturing technology,which comes from the U.S.A.

1.The shell is made of a modified plastic which is anti-scratches and easy to clean as well as keeps the inside BPC material from water absorption.

2.Thickness of the shell:05mm min.

3.The core is still made of bamboo plastic composites.

Picture show of Recycled Plastic Decking

Specification of Recycled Plastic Decking

Name | Recycled Plastic Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Recycled Plastic Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, formaldehyde removal method of Han purple is physical adsorption by palygorskite and sepiolite based, adding diatomite, tourmaline and other natural minerals, after special processing technology is made, in which the pore pore size between 0.27 - 0.98 nm and a crystal arrangement. At the same time is weak, formaldehyde, ammonia, benzene molecules, toluene and xylene in diameter 0.40.62 nm, and it is a polar molecule, so it has the features of preferential adsorption of formaldehyde, benzene, TVOC and other harmful gases, to purify indoor air effect

- Q: What's the function of the plastic film under the wood floor?

- Prevent moisture and moisture, so as not to the floor because of water seepage to the deformation of the wooden floor.

- Q: There is a little water with plastic sheeting can pave the floor?

- The ground with plastic sheets of water on the floor can not beThere is water that the ground is wet, the ground is not suitable for wet floor, because the damp environment easily lead to deformation of the floor.

- Q: Water general plastic floor glue harmful to the human body

- Will affect people's health. If you have laid the domestic PVC roll floor, there is a serious odor, it is recommended that you often open the window ventilation, maintaining indoor polite circulation, reduce indoor pollution.

- Q: PVC plastic floor development trend?

- Before the production of such materials, the country was originally concentrated in Europe, Japan, South Korea, France as the most. Domestic production of special sports flooring manufacturers rarely, as can be produced with the international level of the sports flooring manufacturers are rare. However, China's Enyoo (En Yu) brand PVC plastic sports flooring developed through long time finally achieved breakthrough success. As a leader in the industry in the high-end brand, in many key technical indicators have reached or exceeded the international advanced level

- Q: Domestic anti - slip plastic floor leather with moisture-proof effect

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factories, schools, hotels, hotels, KTV, bars, massage parlors, beauty salons (shops), clothing stores

- Q: Dog feces in the plastic floor on how to clean, 84, washing powder, detergent are used, or brush off, how to do? What cleaning

- Generally buy plastic floor is the choice of coil, plastic floor how to install, plastic floor price, plastic floor how much money

- Q: 2mm thick PVC plastic floor is generally one square meter

- PVC is soft and hard, transparent and opaque, different products, different formulations, and after the amount of plasticizer and filler no number, density difference, common hard transparent PVC is 1.34 g / cubic centimeters, opaque hard PVC to 1.7 also, transparent soft PVC to a minimum of 1.22 so, do not know the opaque.On compromise 1.5g/ cubic centimeters =1500KG/ cubic meters.2mm thick PVC square meter volume is 0.002 square meters. So 2MM PVC sheet weighs about 3KG.

- Q: What is the plastic floor?

- 3.0mm (mm), the scope of application: family room, hotels, restaurants, airports, schools, hospitals, clinics, light industrial factories, offices, offices, laboratories, shopping malls, entertainment, etc. all kinds of cylindrical wall and ground of indoor space, grade quality, special purpose: wear pattern: wood material.: PVC. Product features: vidon material compared with traditional materials, stone plastic floor model as an alternative to products from the function and purpose has its irreplaceable advantages: A, rich colors, easy splicing,.... Manufacturer of plastic floor is Suzhou Zhaoshun Trade Co. Ltd., plastic floor brand: vidon, specifications: place of origin: Taiwan, wandon, specifications: 178mm brand:

- Q: What is the difference between plastic floor leather and plastic floor tile

- The past is the floor leather leather surface decoration materials, only used for luggage, leather products and flooring, floor leather past poor wear resistance, scratch resistance, as well as a pungent odor, poor stability, easy to damage. Now the PVC roll floor has the characteristics of wear resistance, dirt resistance, antibacterial, environmental protection, stability, safety, fire prevention, sound insulation, far better than the previous floor leather.

Send your message to us

Recycled Plastic Decking Made in China with CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords