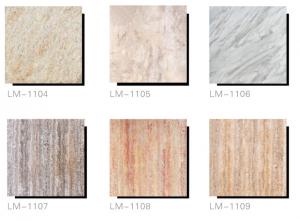

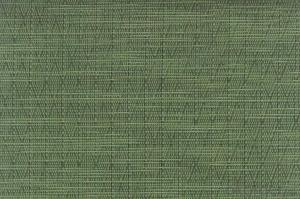

Vinyl (PVC) Tile - Carpet Series

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of vinyl tiles:

1.E1 Formaldehyde

2.Green Policy

3.100% Water Proof

4.Green Policy

Product Fast Details:

1.Size: 12"*12",18"*18",24"*24"

2.Thickness: 1.0mm-5.0mm

3.Wear layer: 0.07mm-1.0mm

4. Surface texture :Leather, BP, Smooth Wood, Registered Embossed Surface.

5. Surface treatment Uv/Pu coating & Beveled Edge available.

6. Backing Dry backing & self-stick

7.Packing: carton and pallet

8.Weight : 3.8kg/sqm for 2.0mm

4.8kg/sqm for 2.5mm

5.6kg/sqm for 3.0mm

Product Advantages:

1, The floor price of options over large areas, suitable for all levels of the people to choose

2, For a wide range of using

3, Stain, acid reduction is good, maintenance-free

4, Flexible, non-slip ,performance is good

5, Wearable, antibacterial, not moth-eaten, moldy

6, Dimensional stability is good, not affected by temperature and humidity affect the deformation of

7, Safety, environmental protection and does not contain formaldehyde

8, Noise noise reduction, Jiaogan comfort

9, Color, pattern rich, fully meet the individual design needs

10, Fire performance, B1 Level

11, Light weight, reduce the building load

- Q: The new rent a house, rough housing, house, do not want to decoration, but the cement really ugly, but the old feeling clean and fresh, a plastic carpet, feel the taste, said that before reading not made of plastic cloth, do not know whether to shop on the ground is also very harmful to me? Want to know now: plastic carpet and cement that is more harmful to human body?

- So take a look at the level of plastic carpet:The carpet is divided into six grades according to the different performance(1) light household level: placed in infrequently used rooms or parts;(2) medium grade or light grade: for master bedroom or dining room;(3) the general level of household or moderate professional use: used for living room, frequent traffic areas such as staircases, corridors, etc.;

- Q: Floor mounted mats are not ordinary plastic films?

- In addition, there is also the original pad overlap in 20mm joints, and tape sealing, although also can achieve similar waterproof effect, but the cushion thickness of 2mm or so, the overlap will have high low, easy to produce noise floor installation. The thickness of plastic film is only about 0.1mm, although the overlap will not produce high and low, no effect on the pavement.

- Q: What is the difference between PVC plastic floor and composite floor?

- PVC floors and wood floors: wood floors can be broadly divided into three categories: solid wood flooring, solid wood flooring and laminate flooring. The wood floor is natural materials, synthetic materials have irreplaceable advantages, non-toxic and tasteless, comfortable, warm in winter and cool in summer.

- Q: Self adhesive stone plastic PVC floor leather will not stick it

- The harmful substances of floor leather products mainly refers to the content of heavy metals and the amount of volatile substances. Heavy metals are mainly cadmium, lead, and so on, the limited volatile mainly refers to alcohol, toluene and other substances. Some of the smaller, do not pay attention to the quality of the products produced by enterprises mostly contain these substances, and the content exceeded. So in the selection of the product, should choose to buy large manufacturers, brand-name products. First of all, the need to lay the floor of the room to clean up, uneven terrain with cement scraping once, to keep the ground level. Second, the correct calculation of the living room area and then spread the floor tile floor on the ground, static 30 ~ 60 minutes, to be flat after the formation of the roll floor splicing. In the splicing must use adhesive bonding, or a long time easy to roll edge, thus affecting its life.

- Q: Spread a layer of plastic cloth under the wooden floor

- Wood flooring below you have plastic, also called moistureproof layer, and a layer of linoleum or plastic cloth, can cut off the ground condensation of water vapor, and let it pass around the foot of a wall left side seam, emitted into the air. Moisture proof material integrity, damage or joints should be repeated cover. Now some of the lower ground floor of the house to do a half basement treatment, can also play a better role in moisture.

- Q: What is the home improvement PVC plastic floor

- Raw material and production process. The multi-layer composite sheet is composed of a bottom layer, a printing layer and a wear-resistant layer, and the quality of the three kinds of raw materials directly determines the quality of the plastic floor. Bottom layer: at present, the domestic manufacturers can use the bottom material can be divided into two categories, namely, new materials and recycled materials. However, the use of recycled materials produced plastic floor, its quality is not as good as the use of new materials flooring. The bottom material stepped up elastic strong, the water is not easy to deform, and is not easy to shrink, use a long time does not appear warped edge; and the recycled material made of bottom material almost no flexibility, the water will appear obvious swelling caused by edge tilt, if winter temperatures drop too fast will have obvious shrinkage thus, the influence of ground appearance. As consumers in general do not have the ability to distinguish the quality of the material, so we recommend that consumers buy branded products, do not covet cheap use of cottage PVC floor.

- Q: Is it the heat of the plastic sheeting does not affect it? Do you really have a moisture-proof effect?

- There are a small number of plastic sheeting practices, the effect is not very good.

- Q: What are the main construction process of laying plastic floor

- The main construction process of laying plastic floor.(1) semi rigid plastic plate:Primary treatment, elastic line, plastic floor wax, degreasing, scraping, laying, maintenance, rolling stick towel.

- Q: PVC plastic floor glue thickness can be used for welding

- Generally 1.6 mm thick can also be welded! PVC floor is generally used PVC floor glue paste, PVC floor is divided into two kinds

- Q: Our hostel is covered with plastic foam, so it's hot now

- It's hot now? More mopping the floor, increasing the evaporation area of water, air conditioning, ha ha

1. Manufacturer Overview

| Location | Zhangjiagang, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Europe; North America; South Amercia; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Zhangjiagang;Shanghai |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 150 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Vinyl (PVC) Tile - Carpet Series

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords