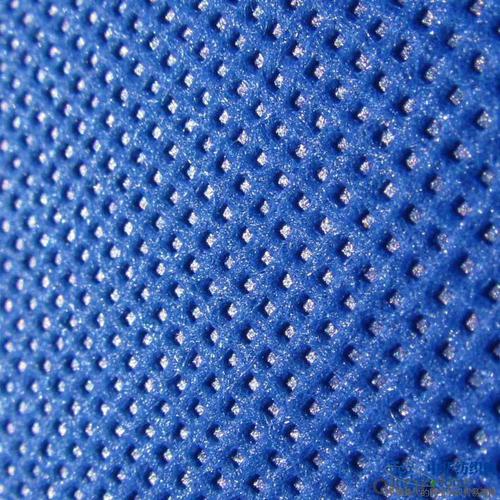

Recycled needle punched ,PET non woven fabric, Bulk Cheap felt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characters of nonwoven fabric;

1.no-toxic ,breathable ,mothproof ,anti-bacteria ,eco-friendly .

2.original manufacturer with good quality and cheaper price .

3.many colors and function product for you choose .

4.good service and timely delivery .

PP Spunbond Nonwoven fabric;

1.100% PP;

2.Machine width : 2.1M; 2.4M

3.Weight: 9-250g;

4.Color: Any color is available

Usage of the nonwoven fabric;

1.Medical : face mask ,cap ,bedsheet , disposable underwear ,protective clothing ,surgical gown, curtain,etc.

2.Industry : waterproof ,roof material ,dam cloth .

3.Packing : nonwoven bag ,gift bag ,storage bag , home textile, pillow, cushion, mattress packing,etc.

4. Agriculture: agriculture cover, plant cover, weed stop, weed barrier, garden fleece, frost protector

FUNCTION:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

APPLICATIONS:

1. Weed block for landscaped garden beds

2. Permeable liners for planters (stops soil erosion)

3. Weed control under wooden decking

4. Geotextile for separating aggregate / soils under walkway blocks or bricks

5. Assists in preventing paving from settling unevenly

6. Landscape fabric prevents soil erosion

ADVANTAGES:

1. Lower labour costs as no weeding maintenance for years;

2. Water seeps through and can conserve soil moisture for improved growing conditions;

3. Air escapes – humidity rises through the mat for a more controlled growing environment;

4. Increase crop yields close to 25% due to improved growing conditions and absence of water stress and competition of nutrients absorption from weeds;

5. Minimises bacteria and fungus problems especially Algae;

6. Strong, woven construction or pressed fibre sheet resists tears and punctures;

7. Resistant to mildew, rot, water, sunlight and most of the agricultural chemicals

8. Fertilizer is applied on the mat, thus helping the owner or estate manager to monitor the progress of manuring;

9. Prevents soil erosion or leaching of soil nutrients or fertilizers applied;

10. Environmental friendly.

FAQ:

Q .What is the material of the non woven fabric ?

A .PP spunbond non woven fabric

Grade A: 100% Polypropylene

Grade B: 90% Polypropylene +10% filling

Q .What about the width of the non woven fabric ?

A .We can cut the fabric as your requirement. Our width of machine is 240cm, so the max of the width is 240cm

Q .What about the color ?

A .Any color is available. You just need to give me the Panton Num or send me your sample. Then we will make the color samples to you for approve

Q .What about the GSM ?

A .The thinnest of the fabric that we can produce is 9g, and the thickest is 250g. Normally the fabric that used in bag making is 50-100g, the agricultural used is 17-50g, the home used fabric is 40g and so on...

Q .What about the delivery time ?

A .We can finish the production in 2-3 days (40ft HQ)

Q .What about the price ?

A .We are the factory of the PP nonwoven fabric, We can supply you with good quality and favorable price

- Q: Textile industry after finishing what pollution, especially air pollution

- At least chronic poisoning for humans and animals is usually the government in order to create achievements or to meet the personal interests of individual officials will be so because of chronic poisoning, after all, there are three or five years or even 30 years of concealment proposed to the Provincial Environmental Protection Office to call complaints or petition

- Q: The weight of the textile fabric

- This is calculated using the formula, we are Jiangyin snow lotus wool mill, from raw materials to finished products need to be calculated, the guests need 1000 meters finished cloth, weighing 600 grams, the composition is 50 wool 50 polyester, and that need to calculate the amount of yarn , Yarn thickness, the weight of raw materials, these formulas please see from below

- Q: What are the textiles?

- Textile fiber processed by weaving products called textiles. According to the use can be divided into clothing with textiles, decorative textiles, industrial supplies three categories.

- Q: What is the textile technology profession now?

- Dyeing and finishing technology; this course more systematically describe the various textile fiber products in the dyeing and finishing of the basic process and process conditions, and the principles and commonly used machinery and equipment for a brief introduction, so that beginners master the basic knowledge of dyeing and finishing The

- Q: What are the invoices for the textile industry?

- If you are the general taxpayer of the production type, the raw material of the purchased textile is the incoming invoice

- Q: What is eco textile?

- From the perspective of production ecology, control, including from the fiber cultivation, breeding, production to the whole process of product processing on the environment pollution, the product itself is not "pollution"

- Q: Do you need to do environmental protection for dry textile processing?

- Family business is to all the property owned by the family, personal business is funded by the individual property.

- Q: Analysis of import and export of textile

- The growth rate fell 6.2 percentage points. Textile and apparel exports totaled $ 292.1 billion in 2013, an increase of 37.8% from 2010, an average annual growth rate of 11.3%, down 3.8 percentage points from the previous year's 15.1% average annual growth rate.

- Q: What is the difference between the mesh pattern on the textile structure?

- Chemical fiber aging problems: such as acrylic fabric folds easily broken, wear, can be added to other fiber blends to enhance his performance. Sun sun exposure is also easy to cause the aging of fiber, fabric fracture.

- Q: Jiangsu Province, more than a large number of textile and garment industry

- How to deal with today's increasingly fierce competition in the textile market, bigger and stronger city textile industry, to speed up the realization of Nantong textile market into the city's goal, which is "Eleventh Five-Year" period Nantong textile industry shoulders the arduous task.

Send your message to us

Recycled needle punched ,PET non woven fabric, Bulk Cheap felt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords