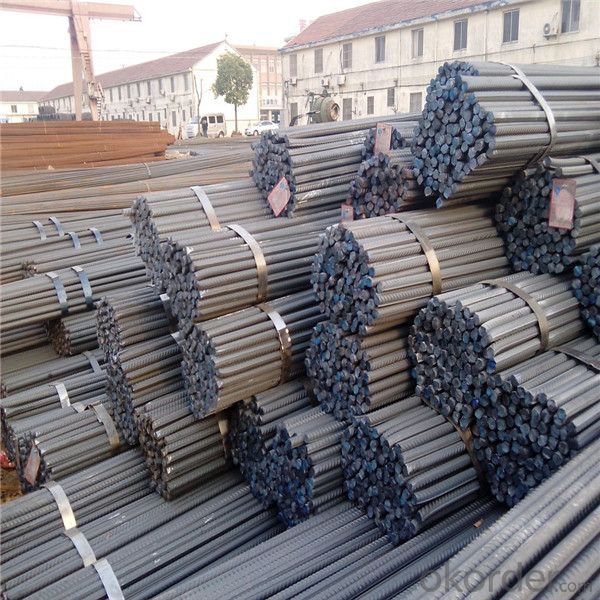

Rebar Price Per Lb - Iron Rods of 6-25mm HRB400 HRB500 for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is an

iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:What are the guidelines for splicing steel rebars in a structure?

- The guidelines for splicing steel rebars in a structure are as follows: 1. Ensure proper design: The first step is to have a detailed design of the structure, which includes the required length and location of rebar splices. The design should follow the applicable building codes and standards. 2. Use approved methods: It is crucial to use approved methods for splicing steel rebars. The most common methods include lap splicing, mechanical splicing, and welded splicing. The selected method should be in compliance with the design requirements and accepted industry practices. 3. Determine splice length: The splice length is determined based on the structural requirements and the type of rebar being used. It is recommended to consult the design engineer or refer to the code requirements to determine the appropriate splice length. 4. Prepare the rebars: Before splicing, rebars should be cleaned of rust, scale, oil, or any other contaminants that may affect the bond strength. The ends of the rebars should be clean and free from deformations or irregularities. 5. Splice location: The location of the splice is critical and should be as per the design specifications. Splices should not be placed in areas subjected to high stress or where they may affect the structural integrity of the member. 6. Reinforcement continuity: Splicing should maintain the continuity of reinforcement to ensure the structural integrity. Adequate overlap or connection strength should be achieved to transfer loads between the spliced rebars. 7. Proper installation: During splicing, it is important to follow proper installation procedures. This may include using appropriate splicing materials, ensuring correct alignment and fit, and applying the recommended torque or tension for mechanical splices. 8. Quality control and inspection: Regular inspections should be conducted during and after the splicing process to ensure compliance with the design and quality standards. This may involve visual inspection, non-destructive testing, or load testing as required. 9. Documentation and record-keeping: It is essential to maintain proper documentation of the splicing process, including details of the method used, splice length, location, and any deviations from the design. This documentation helps in ensuring traceability and accountability. 10. Compliance with codes and standards: Lastly, all splicing activities should comply with the relevant building codes, industry standards, and specifications. It is advisable to refer to the specific code requirements applicable to the region and seek professional advice if needed.

- Q:How are steel rebars stored and transported?

- Steel rebars, also known as reinforcing bars, are commonly used in construction projects to provide strength and stability to concrete structures. Proper storage and transportation of steel rebars is essential to maintain their quality and prevent any damage or accidents. When it comes to storage, steel rebars are typically stored in a designated area, commonly known as a rebar yard or laydown yard. This area should be clean, well-drained, and free from any debris or organic materials. Rebars are usually stacked in bundles or placed on elevated racks to prevent contact with the ground, which could cause corrosion or contamination. To ensure safety and ease of access, rebars should be organized and labeled based on their sizes and grades. This helps construction workers identify and retrieve the required rebars efficiently without causing any disruption or delays in the project. In terms of transportation, steel rebars are often loaded onto trucks or trailers for delivery to construction sites. It is crucial to secure the rebars properly during transportation to prevent any shifting or movement that could cause damage to the rebars or compromise the safety of the vehicle. Rebars can be transported in various ways, depending on their length and quantity. They can be bundled together using wires, straps, or steel bands to keep them in place. Additionally, wooden or metal supports can be used to prevent the rebars from bending or sagging during transit. During transportation, it is important to consider weight restrictions and road regulations to ensure compliance and safety. If rebars need to be transported over long distances, it is essential to coordinate with logistics companies that specialize in handling heavy and oversized cargo. In summary, steel rebars are stored in designated areas such as rebar yards, where they are stacked, labeled, and protected from corrosion and contamination. When it comes to transportation, rebars are secured using wires, straps, or steel bands and loaded onto trucks or trailers. Proper handling and adherence to regulations are crucial to ensure the safety and integrity of the rebars during storage and transportation.

- Q:Can steel rebars be used in structures with high aesthetic requirements?

- Yes, steel rebars can be used in structures with high aesthetic requirements. While rebars are primarily used for their structural strength and reinforcement purposes, they can also be incorporated into architectural designs to enhance the visual appeal of a structure. With various surface finishes and coatings available, steel rebars can be customized to meet specific aesthetic requirements, ensuring they blend seamlessly with the overall design and aesthetics of the structure.

- Q:How do steel rebars provide reinforcement to concrete?

- Concrete is reinforced by steel rebars, which act as tension members. When loads are applied to the concrete, such as the weight of a structure or external forces, it tends to crack and fail under tension. To counteract this weakness, steel rebars are embedded within the concrete. Made of high-strength steel, the rebars have a much higher tensile strength than concrete. During the pouring of concrete, the rebars are strategically placed throughout the structure, typically in areas where tension forces are expected. These areas include beams, columns, and slabs. As the concrete cures and hardens, it forms a strong bond with the steel rebars. When external forces are exerted on the concrete, like the weight of a building or lateral forces from wind or earthquakes, tension forces are generated within the concrete. However, instead of causing the concrete to crack and fail, the rebars bear the majority of the tension. Due to the high tensile strength of the steel rebars, they can resist the tension forces, preventing the formation of cracks and ensuring the integrity and structure of the concrete. The rebars act as reinforcement by evenly distributing the tensile forces throughout the concrete, enhancing its overall strength and durability. Moreover, rebars offer additional benefits to concrete structures. They can mitigate the effects of temperature changes, prevent shrinkage cracks, and enhance resistance to corrosion caused by environmental factors. In conclusion, the use of steel rebars significantly improves the structural integrity and lifespan of concrete, enabling it to withstand various loads and external forces over time.

- Q:How are steel rebars protected from concrete spalling?

- Steel rebars are protected from concrete spalling through the use of various methods and techniques. One common method is to provide a concrete cover over the rebars. This means that the rebars are embedded within the concrete structure, ensuring that they are not directly exposed to external elements or conditions that could cause spalling. The thickness of the concrete cover is typically specified in construction codes and standards to ensure adequate protection. Another way to protect steel rebars from concrete spalling is by using corrosion inhibitors. These inhibitors are typically added to the concrete mix during the construction process. They work by reducing the corrosion rate of the steel rebars, thereby protecting them from spalling caused by rusting and corrosion. In addition to concrete cover and corrosion inhibitors, proper concrete mix design is crucial in protecting steel rebars. The use of high-quality concrete with appropriate water-cement ratio, sufficient strength, and proper curing greatly enhances the resistance of the concrete against spalling. This ensures that the rebars remain securely embedded within the concrete structure and are not exposed to moisture or other deteriorating agents that could lead to spalling. Furthermore, proper construction practices such as adequate compaction of concrete, proper placement and alignment of rebars, and effective waterproofing measures also contribute to the protection of steel rebars from concrete spalling. These practices help to minimize the chances of moisture ingress and the formation of cracks or voids that could expose the rebars to the risk of spalling. Overall, a combination of concrete cover, corrosion inhibitors, proper concrete mix design, and appropriate construction practices are essential in protecting steel rebars from concrete spalling. By implementing these measures, the durability and longevity of concrete structures can be significantly improved.

- Q:Can steel rebars be used in reinforced masonry walls?

- Yes, steel rebars can be used in reinforced masonry walls. The rebars are typically embedded within the masonry structure to provide additional strength and stability.

- Q:What is the effect of overloading on steel rebars?

- The effect of overloading on steel rebars can lead to various consequences, including deformation, structural failure, and reduced load-bearing capacity. Overloading can cause the rebars to bend, twist, or even break, compromising the overall integrity of the structure. Excessive loads can also result in cracks or fractures in the rebars, which may ultimately lead to catastrophic failures. To ensure the structural safety, it is vital to adhere to the recommended load limits and avoid subjecting rebars to excessive loads.

- Q:What are the advantages of using ribbed steel rebars?

- There are several advantages to using ribbed steel rebars. Firstly, the ribs on the surface of the rebar provide enhanced bond strength with the concrete, ensuring better load transfer and reduced slippage between the two materials. This results in improved structural integrity and increased resistance to cracking and deformation. Additionally, the ribbed texture also enhances the rebar's ability to withstand seismic forces, making it an ideal choice for earthquake-prone regions. Moreover, the increased surface area of the ribs allows for better corrosion resistance, extending the lifespan of the rebar and minimizing maintenance costs. Overall, ribbed steel rebars offer superior performance, durability, and safety in reinforcing concrete structures.

- Q:How do steel rebars contribute to sustainable construction practices?

- Steel rebars contribute to sustainable construction practices in several ways: 1. Durability: Steel rebars are highly durable and have a long lifespan, which reduces the need for frequent replacements or repairs. This helps in minimizing waste generation and conserving resources. 2. Structural strength: Steel rebars provide superior strength and structural integrity to reinforced concrete. This allows for the construction of tall buildings and structures, reducing the need for land consumption and promoting vertical growth in urban areas. 3. Energy efficiency: Steel rebars are produced using energy-efficient manufacturing processes, reducing the carbon footprint associated with their production. Additionally, their use in reinforced concrete structures improves energy efficiency by reducing the need for additional insulation materials. 4. Recyclability: Steel rebars are 100% recyclable, meaning they can be melted down and reused in new construction projects. This reduces the demand for virgin steel, conserving natural resources and reducing greenhouse gas emissions associated with steel production. 5. Waste reduction: The use of steel rebars in reinforced concrete structures reduces the amount of construction and demolition waste generated. By providing a strong and durable structure, it minimizes the need for frequent renovation or replacement, thus reducing waste generation in the long run. 6. Seismic resistance: Steel rebars enhance the seismic resistance of buildings and structures by improving their ability to withstand earthquakes and other natural disasters. This ensures the safety of occupants and reduces the reconstruction efforts required after such events, contributing to sustainable development. Overall, the use of steel rebars in construction promotes sustainability by reducing waste, conserving resources, improving energy efficiency, and enhancing the durability and resilience of structures.

- Q:What is the role of steel rebars in minimizing the risk of progressive collapse?

- Steel rebars play a crucial role in minimizing the risk of progressive collapse in structures. Progressive collapse refers to the failure of a building or structure due to the localized failure of a primary structural element, which then leads to the failure of adjacent elements and a collapse of the entire structure. The primary function of steel rebars in this context is to enhance the structural integrity and provide strength to critical load-bearing elements, such as columns, beams, and slabs. By reinforcing these elements with steel rebars, the structure becomes more resistant to sudden and catastrophic failures. Steel rebars are typically embedded within the concrete, forming a composite structure known as reinforced concrete. The rebars act as tensile reinforcements, counteracting the concrete's weakness in tension. When subjected to loads, the rebars bear the tension forces while the concrete resists compression forces. This combination allows for a more balanced load distribution and prevents localized failures. In the event of an unexpected failure or an extreme event, such as an explosion or impact, steel rebars play a critical role in preventing progressive collapse. They provide additional ductility and redundancy to the structure, ensuring that even if one element fails, the load can be redistributed to surrounding elements, preventing a domino effect of failure. Moreover, steel rebars contribute to the overall stability of a structure by increasing its load-carrying capacity. By reinforcing structural elements, they allow for increased spans and higher design loads, reducing the risk of overloading and potential failure. Regular inspections and maintenance of steel rebars are essential to ensure their effectiveness in minimizing the risk of progressive collapse. These inspections involve checking for corrosion, proper placement, and adequate cover of the rebars to protect them from environmental factors that may compromise their integrity. In conclusion, steel rebars play a vital role in minimizing the risk of progressive collapse by reinforcing critical load-bearing elements, enhancing structural integrity, and providing redundancy. They enable structures to withstand unexpected failures and extreme events, ensuring the safety and stability of buildings and infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar Price Per Lb - Iron Rods of 6-25mm HRB400 HRB500 for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords