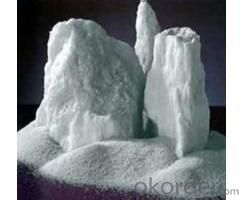

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- There is no detailed stipulation for ultra-thin fire retardant coating, and the thickness of the inside is the fire resistance limit shall reach certain time(at least). In engineering, the thickness of the fire retardant coating is generally determined according to the manufacturer's testing report. We use thin fire retardant coating for steel structure: if the fireproof limit is 2.5 hours. the thickness should be 4.9mm. If fire-resistant limit is 2 hours, the thickness shall be 3.5mm. If the refractory limit is 1.5 hours, the thickness shall be 1.75mm. If the limit is 1.0, the thickness is 1.17mm hope my answer can help you

- Q: Which are fireproofing external wall materials?

- According to combustion performance, external wall thermal insulation materials are classified as Grade-A and Grade-B. Grade-A refers to incombustible material and Grade-B combustible material. A few years ago the fire in CCTV building and Shenyang Hotel were caused by Grade-B material. Currently Grade-A material is more commonly uesd and less expensive than Grade-B material. Grade-A material can be divided into thermal mortar, phenolic foam board, rock wool board, foam cement board, etc. Thermal mortar is easy for construction and unexpensive, but it is also easy for faking due tou its simple procesing. It is recommended to find a large factory whihc has gone through the formalities.

- Q: who knows the uses of refratories?

- Of course, the role of the refractory material is fireproof, generally used in large buildings. It can reduce casualties and economic losses caused by the fire. it also can be used on the chemical instruments. ! !

- Q: How to choose thermal insulation materials for flood heating?

- 1, Select the appropriate floor material suitable for radiant floor heating. The floor radiant heating system mainly transfer heat through the ground concrete and the ground material to the room. Therefore in the heating season the ground material will always be heated during heating season. Therefore, it is better to choose stone materials and compround floor plate insensitive to tenmperature change with good heat dissipation and functions. Currently, wood floor is not suitable for the ground radiant heating system. 2, choose the pipe with anti permeability performance. Plastic floor heating pipe itself has a certain air permeability, if oxygen penetrates in it is prone to oxygen erosion and system's mental device will be eroded, resulting in the risk of leakage. Therefore in order to ensure the reliable operation of the heating system, the selected pipe must have anti oxygen permeation performance, and meet the standard stipulated by the DIN4726 oxygen permeation quantity: and be less than 0.1mg\L.d at 40 C.

- Q: How to prolong the furnace age of Induction furnace by using fireproof materials?

- magnesia solid materials have thermal endurance and erosion/ performance and its change of temperature is likely to cause cracks. properties of materials (aluminum) in such case have to be taken into consideration.

- Q: What are the requirements for the performance of refractory materials?

- Refractory materials should have very high refractoriness, high temperature heat load and resistance to softening, melting; with high volume stability, resistance to high temperature and heat load, volume shrinkage and only uniform expansion; high strength at room temperature and high temperature strength, high load softening temperature, under the joint action of heat load and heavy load, no loss of strength, creep collapse; Electric furnace analysis should have good resistance to thermal shock, resistance to rapid temperature changes, no crack, not flaking; with excellent slag resistance.

- Q: how long is the fire endurance of plasterboard?

- fireproof endurance can reach a maximum of 4hours, suitable for a variety of public buildings firewall, and partitions for public exit passageway, reaching standard level of fireproof. the lightweight partition made of gypsum board and steel stud is mainly for dividing architecture space. Rock wool can be filled in the mddle according to its design requirements, using different series of gypsum board, steel stud. the walls may have fire resistance and sound insulation property of various degrees.

- Q: What is the fireproofing requirements of external wall thermal insulation materials?

- According to the "building external wall insulation fire barrier zone technical regulations" to be published: it is not less than the level B2. But before the procedure was published, it should be strictly implemented the document, level A is the best, I hope to help you, hope to adopt

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

- Q: How to classify fire resistance rating of brick-concrete structure?

- In order to ensure the safety of the building, the fire protection measures must be taken to make it have a certain degree of fire resistance, even if there is a fire, it will not cause too much damage. According to the national conditions of our country, and in the light of other countries standards, < high-rise civil building fire protection design specification > defines fireproof rank of high-rise civil buildings into level one and two; < code for fire protection design of buildings > divides the rank into level one, two, three, four, level one is the highest level, level four is the lowest. Besides that the minimum fire resistance of the building component is specified, buildings of fire resistance rating also specified requirements for combustion performance. Because the component with the same fire resistance limit is different, it is different in the fire.According to our country national standard < building design fire protection code >, the fire resistance rating of the building is divided into four levels. The fire resistance of a building is determined by the combustion performance and fire resistance of building components (such as beams, columns, floors, walls, etc.). Generally speaking, the fire resistance building of level one is a mixed structure of reinforced concrete structure or a mixture of brick wall and steel concrete structure; the fire resistance building of level two is a mixed structure of steel truss structure, reinforced concrete column and brick wall; the fire resistance building of level three is brick-wood structure made of wood roof and brick wall; the fire resistance building of level four is combustible structure which is composed of wood roof and non-combustible wall.

Send your message to us

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords