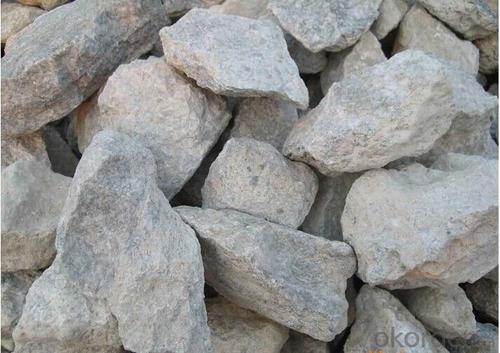

Raw Materials for Refractory:Dead Burned Magnesite Ore

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product feature:

high temperature performance and high-density, strong anti-permeability ability and easy to rapid sintering, very thin sintered layer,good thermal shock stability, strong slag-resistance, long service life and so on.

Product function:

Apply to the construction of bottom and wall of all kinds steel making electric arc furnace and ferroalloy smelting furnace for hot charging of hot metal and second hand steel

Product usage:

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect .

Product Advantage:

We can produce the products of the Dead-burned magnesite are selected natural magnesite, it is produced by mine-selecting, purifying, calcimine in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, electric furnace bottom and furnace's lining tamping.

Classifi cation | Brand | Chemical composition(%) | Size mm | Application | |||||

MgO (≥) | SiO2 (≤) | Fe2O3(≤) | CaO (≤) | Al2O3(≤) | C/S (≥) | ||||

Magnesite | M47A | 47 | 0.3 | 0.28 | - | 0.1 | 2 | 0-25; 25-350 | Fused Magnesite;Caustic Calcined Magnesite |

M47B | 47 | 0.4 | 0.30 | 0.6 | - | - | |||

M47C | 47 | 0.6 | 0.30 | 0.6 | - | - | |||

M46A | 46 | 0.8 | 0.30 | 1.2 | - | - | 0-25 | Fused Magnesite; Dead Burned Magnesite;Caustic Calcined Magnesite; | |

M46B | 46 | 1.2 | 0.4 | 0.8 | - | - | 25-350 | ||

M45 | 45 | 1.5 | - | 1.5 | - | - | 25-350 |

| |

M41 | 41 | 2.0 | - | 6.0 | - | - | 25-350 | High Calcium Synthetic Magnesite | |

Magnesite Dolomite Ore | MCa-10 | 22 | 2 | - | 10 | - | - | 25-350 | Calcium Magnesite |

MCa-6 | 22 | 2 | - | 6 | - | - | 25-350 | ||

Dolomite | MCa-28 | 20 | 1.0 | - | 28 | - | - | 25-30 | Dolomite Clinker |

MCa-26 | 20 | 1.5 | - | 26 | - | - | 25-30 | ||

- Q: What is streaming fireproof material?

- Since streaming fireproof material has less surface energy, so when it is placed in a location to be used, it can be automatically filled so long as mixed with water at proper ratio. And then using vibrator or vibrostand and other tools to compact the mixture so as to satisfy the use requirements. Therefore, it does not require vibration, and it has less friction force between the particles. Generally hydraulic refractory castable must be mixed with water at proper ratio when in construction . While, the concept of "streaming" is in terms of refractory castable.

- Q: How long can gypsum board endure fire?

- Fire endurance refers to the fire-resistent limit of the whole system of light-gauge steel structure coupled with gypsum. It does nor merely refers to gypsum board. Fire endurance of the common gypsum board with the thickness of 9.5mm keeps 1.5 hours. Those gypsum board with the thickness of 12mm has a fire endurance of 3 hours.

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- I am engaged in construction. Refractory material does not necessarily belong to construction industry. Fire resistance is only a part of material?performance. Indeed, there are many places requiring refractory accorded with fire resistant level.

- Q: Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- When the steel surface derusted, it generally needs to brush rich-zinc primer before spraying fireproof coating. Fireproof coating plan itself includes anticorrosion plan, and fireproof coating is just a layer of coating plans, which is an intermediate layer in general. Fireproof coating plan generally includes primer, fireproof coating and finishing paint. Some fireproof coatings can be directly painted on the bare steel elements without primer and finishing paint. Galvanized surface generally is not necessarily needed for brushing fireproof coating. Fireproof and galvanized surface have relatively poor bond strength, so it is advisable to brush transitional lacquer or micaceous iron on the galvanized surface.

- Q: What are the qualifications of refractory industry?

- 1 business license 2 tax registration certificate 3 organizing institution bar code 4 production permit

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: What do refractory materials include?

- It is so difficult.

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: What are the best refractory materials in 2,400 Celsius degree?

- It is the purpose that decides what kind of materials you should use. What you have said is 2,400 Celsius degree, right? It is about the fire resistance of the material or the required temperature of it?

- Q: How do refractory materials apply into pyrophyllite?

- Generally speaking, shaped refractory materials require of some powdery materials like spray grouts and iron trough in addition to pyrophyllite brick made of a mixture of pyrophyllite aggregate and powers.

Send your message to us

Raw Materials for Refractory:Dead Burned Magnesite Ore

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords