Raw Materials for Refractory:84% Shaft Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

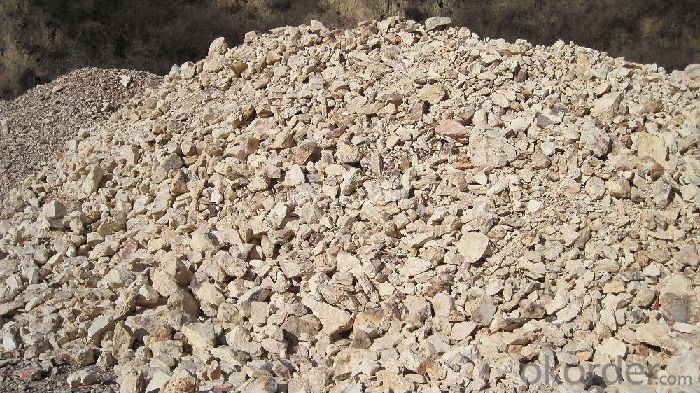

84% Shaft Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the materials of insulation firebricks?

- The furnaces of firebricks are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

- Q: What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- The main material is quartz sand and it is the cheapest, and can resist 1500℃ without any difficulty.

- Q: How to prolong the furnace age of Induction furnace by using fireproof materials?

- magnesia solid materials have thermal endurance and erosion/ performance and its change of temperature is likely to cause cracks. properties of materials (aluminum) in such case have to be taken into consideration.

- Q: What are the common refractory insulation cotton material?

- I know less about this, I hope the following will help: Fire resistant thermal insulation material mainly refers to inorganic thermal insulation material and compround thermal insulation material. According to the shape can be divided into: Fibrous finishes, slag wool, rock wool, glass wool, aluminum silicate cotton. ceramic fiber, micro pile of diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete etc., foam like bubble glass, volcanic ash glass, foam clay, foaming concrete, paste powder polystyrene particles insulation slurry

- Q: The principle of choosing fire-resistant material in Thermal Energy and Power Engineering equipment.

- What thermal equipment? The most simple principle is durable, low cost and with no environmental pollution.

- Q: What are the differences of ceramics and refractories? Is the ceramics belonging to refractories?

- They are not the same. If you say the ceramic fibers, they have some common points because the ceramic fiber is one of the refractory. It is belonged to the lightweight refractory which can be considered a new type of refractory with the main ingredient of aluminum silicate (including aluminium oxide and silicon?dioxide).

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

- Q: What are the specifications of fireclay bricks?

- Dimensions of refractory bricks : 230 * 115 * 65mm

- Q: Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q: What kind of materials are needed to make refractory bricks?

- Fubang Decoration of Anhui province help you with the question: According to requirements, there are different materials, acid refractory material, such as silica bricks; neutral refractory material, such as high alumina brick; and basic refractory material such as magnesia brick.

Send your message to us

Raw Materials for Refractory:84% Shaft Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords