Raw Materials for Refractory:50% Shaft Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

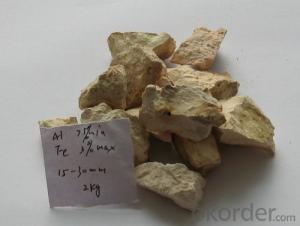

50% Shaft Kiln Alumina Calcined Bauxite Raw Material for Refractory

Specifications

1. We directly supply calcined bauxite

2. Al2O3:50%/70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Applications of 74% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

1.Aluminium metallurgy.

2.Precision casting/Investment casting: bauxite grog fines can be made into mold for precision casting.

3.Refractory: high alumina bauxite's refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance.(Al2O3 ≥48% with low Fe2O3)

4.Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under2000°C-2200°C in the electric arc furnace. After a series of processing, it can become aluminium silicate refractory fiber, which can be made into fiber blanket,plate,cloth.

5.Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining performance.

6.Producing bauxite cement.

7.Abrasives.

8.Ceramics industry.

9.Chemistry industry for all kinds of aluminium compound.

Our services

1.We can offer you the customer size services.

2.We can offer you the best quanlity and price.

3.We can offer you the related test report,both at factory and the third party.

4.Packaging: 25/50kgs per bag or as client's requirement.

5.We have sufficient manufacturing capability to delivery the goods safely and in time,because we have strong : own reliability testing lab ,most importantly, we owed productive factory.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what kind of refractories is used to make the industrial silicon furnace mouth long life?

- Fused zirconia corundum brick, the smelter of the glassworks is used this kind of lining, and you can contact by private letter.

- Q: How can refractory material of the electric furnace be used for longer.

- Minimize mechanical shock, Electrical furnace commonly referred to must be electrical arc furance. The wall of electric arc furnace should be constrcuted with magnesite carbon brick. Its hearth permanent layer should be constrcuted with mansornary magnesia brick. High alumina brick is usually used to aviod furnace cover suddenly get hot and cold. But its service life is lower. At present integral casting furnace cover is made of alumina magnesia. Terminal will be created even without the use of refractory material. Consumption is much faster if using refractories material or whole knottiing mainly.

- Q: Refractory material, refractory brick

- High alumina brick is commonly used in high aluminum, LZ-75, LZ-65 and LZ-55, as well as high alumina brick for blast furnace, high alumina brick for hot blast furnace, and low creep high alumina brick

- Q: Who knows what is the requirement for fireproofing of interior decoration materials ?

- In addition to the underground building, combustion performance level of interior decoration materials inside windowless room , in addition to a class, should advance 1 level based on the original provisions . Library, archives and rooms storing artifacts, ceilings, walls should use class A decoration materials, and the ground should use decoration materials no lower than class B. When high temperature parts of lighting and lighting lamps and lanterns are close to non - grade A decoration materials should be taken, fire prevention measures such as thermal insulation and heat dissipation must be taken. Combustion performance level of materials used for lighting should be no lower than B. Kitchen ceiling, wall and floor should used class a decoration materials.

- Q: What are the basic requirements of continuous casting for molten steel? What are the requirements for refractory materials?

- The rapid development of the technology of continuous casting refractories so the corresponding development and improvement in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on.

- Q: Which industry does the metallurgy and thermal insulating and refractory material belong to?

- It belongs to the refractory industry, which has its own trade association.

- Q: What is the offer of fire proofing thermal insulation material?

- The following prices are from the Internet and for your reference only. Hainan fire proofing thermal insulation material ceramic fiber paper aluminum silicate fiber blanket/aluminum oxide fiber insulation cotton insulation pipe 12 yuan Hainan multicrystal mullite/calcium silicate corundum ceramic fiber loose wool short fiber fire proofing thermal insulation material non-asbestos high temperature resistant aluminum silicate fiber insulation cotton fire-resistant material ceramic fiber blanket thermal insulation blanket 28 yuan non-asbestos high temperature resistant aluminum silicate fiber ceramic fiber blanket needled felts insulation blanket fire resistant material thermal insulation cotton blanket reference price: 59 yuan

- Q: What is the limit of fireproof rolling shutter?

- Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. Set firewall has difficult sites can use fire shutter fire partition separating, when the back fire surface temperature rise refractory limit determination conditions of fire shutter, the fire resistant limit not less than 3H; when employed does not include back fire surface temperature rise do fireproof limit determination conditions of fireproof rolling curtain, on both sides of the shutter should be set up a separate closed type automatic water spraying system protection, sprinkler system continuation of time should not be less than three hours.

- Q: How to distinguish the fire resistant level of construction materials?

- There are 3 conditions for building components to reach fire endurance, namely: Loss of ability to support; loss of integrity; loss of fire insulation function. As long as one condition occurs, fire endurance is reached and the time before it is called fire endurance. 1), loss of ability to support: If the specimen bearing capacity and rigidity reduce, section area shrink, collapses or deformation exceeds specified numerical value because it cannot bear the load of original design under flame or high temperature, it loses the ability to support. 2), loss of integrity: It mainly refers to the thin wall separating component(such as stairs, windows,partitions, ceiling, etc.) burst or partially collapse under flame or high temperature, and penetrating?fracture or opening appears, and the reverse side even burn. For example, when the floor is under flame or at high temperature, the flame spread to the upper room, which indicates that the integrity has been damaged. 3), loss of fire insulation function: It mainly refers to that seperating components loses thermal insulation and excessive heat conduction. In experiment, if the average temperature of component unexposed surface exceeds 140 ℃, or if any spot at the unexposed surface exceed the initial temperature of 180 ℃, the component loses fire insulation function.

Send your message to us

Raw Materials for Refractory:50% Shaft Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords