Raw Materials for Refractory:81% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

81% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

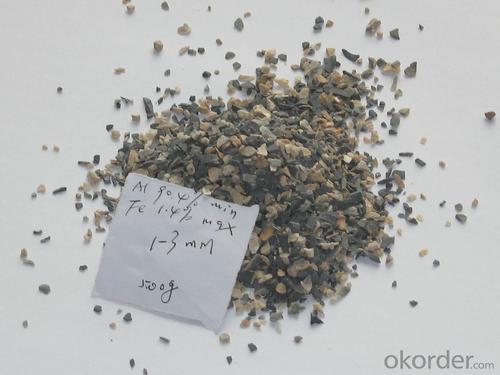

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Application:

1.Aluminium metallurgy.

2.Precision casting/Investment casting: bauxite grog fines can be made into mold for precision casting.

3.Refractory: high alumina bauxite's refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance.(Al2O3 ≥48% with low Fe2O3)

4.Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under2000°C-2200°C in the electric arc furnace. After a series of processing, it can become aluminium silicate refractory fiber, which can be made into fiber blanket,plate,cloth.

5.Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining performance.

6.Producing bauxite cement.

7.Abrasives.

8.Ceramics industry.

9.Chemistry industry for all kinds of aluminium compound.

Grade

| grade | Al2O3 content | Fe2O3 content | TiO2 content | K2O+Na2O content | CaO+MgO content | bulk density |

| 75 | 75%min | ≤ 3.0% | ≤ 4.0% | ≤ 0.3% | ≤ 0.5% | ≥ 2.70 |

| 80 | 80%min | ≤ 3.0% | ≤ 4.0% | ≤ 0.3% | ≤ 0.5% | ≥ 2.80 |

| 85 | 85%min | ≤ 2.0% | ≤ 4.0% | ≤ 0.3% | ≤ 0.5% | ≥ 3.00 |

| 86 | 86%min | ≤ 2.0% | ≤ 4.0% | ≤ 0.3% | ≤ 0.5% | ≥ 3.10 |

| 87 | 87%min | ≤ 2.0% | ≤ 4.0% | ≤ 0.3% | ≤ 0.5% | ≥ 3.20 |

| 88 | 88%min | ≤ 1.8% | ≤ 4.0% | ≤ 0.25% | ≤ 0.5% | ≥ 3.25 |

| 90 | 90%min | ≤ 1.8% | ≤ 4.0% | ≤ 0.25% | ≤ 0.5% | ≥ 3.30 |

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Can anyone tell me what material the first rate fire resistant door is?

- Material of Class A fire doors can be divided into steel and wood, so fire doors can be divided into fireproof steel door and fireproof wooden door. In fact, fire doors of all classes are divided into steel, wood, steel and wood, and other materials (see GB ). Mainly depending on what kind of material the customers want. The fire door is called class A fire door not because of the material but because of the fire-resistant time. The fire resistant time of class A fire door is not less than 1.2 hours and fire doors as long as meeting this condition can be called class A fire doors . The filling material in class A fire doors is generally perlite, whose difference is in thickness. A few of them will use fireproofing materials like foam core board, vermiculite fireproof board, MC composite material and so on. The thickness of class A fire door is usually 50mm. I hope my answer can help you.

- Q: What is the fire resistance thickness of the thin fire-retardant coatings?

- Our thin steelwork fireproof coatings: the fire resistance is 2.5 hours, the thickness is 4.9 mm, the fire resistance is 2.0 hours, the thickness is 3.5 mm, the fire resistance is 1.5 hours, the thickness is 1.75 mm, the fire resistance is 1.0 hours, the thickness is 1.17 mm.

- Q: What are the materials for refractory materials? What are their names?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Solid wood logs are necessary. If it is the type of smoke free material, it will not be necessary. You'd better confirm it with the port of destination. Vietnam has the requirement to smoke

- Q: who knows the uses of refratories?

- 1. Category: chinalco refractory aggregate Al2O3 containing about 35% -40%, high-alumina refractory aggregate containing 55% Al2O3. Widely used in thermal equipment, high-temperature furnace wall, heatable brick bed, chimneys, lining and other basic construction, it is mainly used in military, warehouse, air defense, industrial and mining enterprises, and general industrial furnace, the finest raw materials in cement admixture and expanding agent plant. Having a low density, thermal conductivity, water absorption, fire-resistant thermal insulation properties. Lightweight mullite refractory aggregate: This project uses natural materials to synthesize advanced refractory raw materials. It is a new synthetic materials. lightweight refractory aggregate to make lightweight refractory castables at high temperature has been in short supply. In most cases it is replaced by used light weight brick pieces. the entailing problem is : high-temperature lightweight castable refractory shrinks at high temperatures, affecting the performance of high-temperature lightweight castable refractory. high alumina refractory aggregate is often used.

- Q: Which brand of AAA refractory is good?

- Foshan Nanhai Yanbu Shuying fire-resistant insulation material is very good, and it is a professional company of the production and sale of refractories. Our company specializes in the production of refractory bricks, refractory bricks, refractory castable, refractory aggregate, refractory materials, bauxite, alumina bricks and to undertake the production of various common refractory bricks and non-sizing bricks. The Zhengzhou Fire High Temperature Materials Co., Ltd. is also a good company. It is a collection of R & D and production company. The company mainly produces refractories, refractory bricks, refractory castable, refractory aggregate, refractory materials, special refractory bricks.

- Q: What are the characteristics of the carbon composite refractories?

- The features of carbon composite refractories: 1. It is with an aggressive high thermal shock resistance 2. Good resistance to molten steel and slag

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: How many external wall thermal insulation fireproof material are there

- Inorganic active wall thermal insulation materials, cement foam thermal insulation board, glazed hollow bead insulation mortar, rock wool plate, glass wool plate etc., if used for external wall thermal insulation, rock wool board more frequently used.

- Q: what is steel fire door made of ?

- 1. fire resistance steel door has steel made door frames, door leaf framework and door panels. if the door leaf is filled with nontoxic fire insulation material, added with fireproof hardware accessories, which consists of a door that is fire resistance.

Send your message to us

Raw Materials for Refractory:81% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords