ASTM A105 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM A105 Carbon Steel Round Bars

Products Details

Item | |

Standard | GB/T 700-2006,GB/T 1591-94,JIS G3101-2004, ASTM A36/A36M-05,ASTM A242/A242M-04,ASTM A529/A529M-05, ASTM A572/A572M-06,EN 10025-2-2004 |

Material | Q195,Q215 A,Q215 B,Q235 A,Q235 B,Q235 C, Q235D,Q275,Q275B,Q275C,Q275D,Q295,Q345,Q390,Q420, Q460, SS330,SS400,SS490,SS540,A36,1,GR.36,50(245),55(380),42(290), 60(415),65(450),S185(1.0035),S235JO(1.0114), S235JR(1.0038), S235J2(0.0117),S275JR(1.0044),S275JO(1.10143),S355JO(1.0553), E295(1.0050),E335(1.0060), S235J2W(1.861),S355J2W(1.8965),10#, 15#20# |

Diameter | 4mm~800mm |

Length | 1m,3m,5.8m,6m,12m or as required |

Surface | polished,bright,black,coated,2b,ba,mirror,NO.4,8K |

Package | Standard export seaworthy or as customers’ requirements |

Application

| 1.Mainly used in the manufacture of petroleum, chemical, gas separation and shipping container or other similar devices, such as all kinds of tower vessels, heat exchangers, torage tank and tank car, etc

2.Manufacture all kinds of stamping parts, construction and engineering structure and some of the less important machine structure and parts.

3. Buildings and Bridges,Vehicles, towers and other structures.

4.Used as a floor, workshop escalator, working pedal, ship deck and car plate and so on

5.Make fixed boiler, boiler and other important hull attachments.

6.Pressure vessels, welding gas cylinder steel plate

7.Production of cutting tools, measuring tool and die

|

Export | Ireland,Singapore,Indonesia,Ukraine,Saudi Arabia,Spain,Canada,USA,Brazil,Thailand,Iraq,Russia, Holland,Turkey,Kuwait,Korea,Iran,India,Egypt,Oman,Malaysia,Peru, Vietnam,Mexico,etc

|

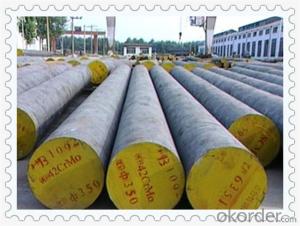

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Can steel round bars be used in corrosive environments?

- The suitability of steel round bars in corrosive environments depends on the specific type of steel and the severity of the corrosion. For instance, stainless steel round bars are well-known for their excellent resistance to corrosion and are widely used in corrosive environments like marine applications, chemical processing plants, and wastewater treatment facilities. These bars are typically alloyed with elements such as chromium and nickel, which create a protective layer on the surface of the steel, preventing corrosion. On the other hand, carbon steel round bars are more susceptible to corrosion and may not be appropriate for highly corrosive environments unless they are properly coated or treated. In such situations, it is crucial to seek advice from experts or engineers to select the right steel grade and take necessary precautions to ensure the durability and performance of steel round bars in corrosive environments.

- Q: What is the difference between a smooth and a deformed steel round bar?

- The main difference between a smooth and a deformed steel round bar lies in their surface texture. A smooth steel round bar has a plain and even surface, typically free from any ridges or indentations. On the other hand, a deformed steel round bar has intentional deformations or patterns on its surface, such as ribs, bumps, or grooves. These deformations provide enhanced bonding with concrete or other materials, increasing the bar's grip and preventing slippage. Deformed steel round bars are commonly used in construction projects that require reinforced concrete structures, while smooth steel round bars are often employed in applications where surface texture is not a crucial factor.

- Q: Can steel round bars be used in the automotive parts industry?

- Indeed, the automotive parts industry does make use of steel round bars. These bars, renowned for their remarkable strength, resilience, and ability to withstand wear and tear, are frequently employed in the production of diverse automotive components. By shaping and sizing these bars to suit the specific needs of axles, drive shafts, suspension components, steering components, and gears, manufacturers ensure that automotive parts are crafted to the highest standards. The utilization of steel round bars guarantees the structural soundness and dependability of these components, rendering them perfectly equipped to endure the rigorous conditions and burdens encountered in the automotive sector.

- Q: Can steel round bars be used for making springs or suspension components?

- Yes, steel round bars can be used for making springs or suspension components. Steel is a commonly used material for these applications due to its high strength and durability. The round bar shape allows for easy fabrication and customization according to the specific requirements of the springs or suspension components.

- Q: How are steel round bars used in the manufacturing of machinery and equipment?

- Steel round bars are widely used in the manufacturing of machinery and equipment due to their inherent strength, durability, and versatility. These bars are typically made from carbon steel or alloy steel and come in various diameters and lengths. One common application of steel round bars is in the fabrication of shafts and axles. These components are crucial for transmitting rotational motion and torque in machinery. Steel round bars provide the necessary strength and stiffness to withstand the forces and stresses experienced during operation. They are often machined to precise tolerances and then heat-treated to enhance their mechanical properties, such as hardness and toughness. Another important use of steel round bars is in the production of gears and sprockets. These components are essential for transmitting power and motion between different parts of a machine. Steel round bars are machined to form teeth or cogs that mesh together, ensuring smooth and efficient operation. The high strength and wear resistance of steel enable gears and sprockets to withstand heavy loads and repetitive motion without deformation or failure. Steel round bars are also utilized in the manufacturing of various machine components such as bearings, couplings, and fasteners. Bearings, for example, rely on the strength and hardness of steel to support rotating or sliding shafts while minimizing friction and wear. Couplings, on the other hand, utilize steel round bars to connect different machine parts, transmitting power and motion efficiently. Steel round bars are also used as fasteners, providing a secure and reliable connection between different machine elements. In addition to these applications, steel round bars are often employed in the construction of machine frames and structures. Their high strength-to-weight ratio makes them ideal for providing structural support and stability. By using steel round bars, manufacturers can build robust and reliable machinery and equipment that can withstand heavy loads, vibrations, and other challenging operating conditions. Overall, steel round bars play a vital role in the manufacturing of machinery and equipment. Their exceptional strength, durability, and versatility make them a preferred choice for a wide range of applications. Whether it is for shafts, gears, bearings, or machine frames, steel round bars provide the necessary mechanical properties to ensure the reliable and efficient operation of machinery and equipment.

- Q: Can steel round bars be used in the aerospace manufacturing industry?

- Yes, steel round bars can be used in the aerospace manufacturing industry. Steel round bars are commonly used in various aerospace applications such as structural components, landing gear, engine components, and fasteners. The high strength and durability of steel make it suitable for these critical aerospace applications. Additionally, steel round bars can be easily machined and formed into complex shapes, allowing for customization and precise engineering requirements in the aerospace industry. Furthermore, steel's resistance to corrosion and its ability to withstand extreme temperatures make it a reliable choice for aerospace manufacturing. Overall, steel round bars are a versatile and widely used material in the aerospace industry due to their strength, durability, machinability, and resistance to corrosion.

- Q: How can steel round bars be protected from corrosion?

- Steel round bars can be protected from corrosion through various methods such as applying protective coatings like paint or epoxy, using galvanization or zinc coating, using corrosion inhibitors, or by implementing cathodic protection techniques such as sacrificial anodes or impressed current systems.

- Q: Can steel round bars be used for making agricultural equipment?

- Yes, steel round bars can be used for making agricultural equipment. Steel is a strong and durable material that can withstand heavy use and provide the necessary strength and stability required for agricultural equipment.

- Q: What are the different types of steel round bar alloys for improved corrosion resistance?

- There are several different types of steel round bar alloys that offer improved corrosion resistance. Some common examples include stainless steel alloys such as 304, 316, and 410, which contain chromium and nickel to create a protective layer against corrosion. Additionally, weathering steel alloys like ASTM A588 and A709 are known for their ability to develop a rust-like appearance that acts as a protective barrier. Other options include duplex stainless steels, which combine the benefits of austenitic and ferritic alloys, and high-alloy steels like Inconel and Hastelloy, which are highly resistant to corrosion in extreme environments.

- Q: What is the maximum molybdenum content allowed for steel round bars?

- The maximum molybdenum content allowed for steel round bars varies depending on the specific steel grade and industry standards. However, in general, the maximum molybdenum content in steel round bars is typically around 0.5% to 1.5% by weight.

Send your message to us

ASTM A105 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords