Flat Rolled Aluminum Coil Indiana - PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of PVDF Coating Aluminum for Building Decorations Description:

Aluminium coated sheetl/ aluminium colour shee is PE (polyester) coating: high molecular polymer as monomer and addition of alkyd, is a UV-resistant coating. It can be classified either as matt or glossy according to your needs. The compact molecule structure makes the point surface luster and smooth, which assures good printing on the panels’ surface.

Aluminium Coated Sheet is widely and mainly used for building decoration, such as ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect.

2.Main Features of PVDF Coating Aluminum for Building Decorations:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

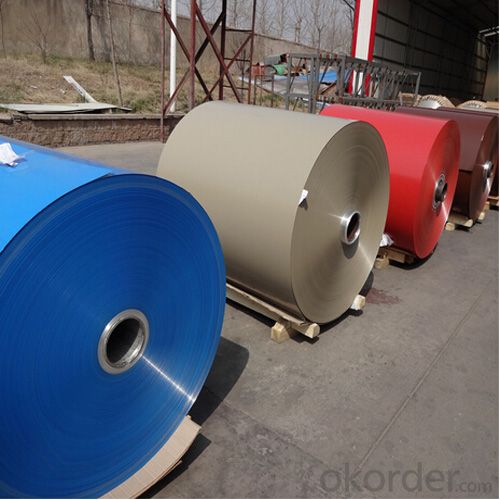

3. PVDF Coating Aluminum for Building Decorations Images:

4. PVDF Coating Aluminum for Building Decorations Specification:

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc. |

Thickness | 0.1~1.5mm |

Width | 100~2200mm |

Application | Decorative Materials |

Surface Treatment | Coated |

Temper | O - H112 |

Hardness | More than 2H |

Yield (≥ MPa) | 160 |

Temper | O - H112 |

Ultimate Strength (≥ MPa) | 175 |

Elongation (≥ %) | 6 |

Packing material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical( eye to sky) or horizontal( eye to wall) |

Standard spec | 1000mm xC, 1200mm xC etc |

Shipping | Container Loading or Bulk Pack |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How are aluminum coils protected against dust and dirt during storage?

- Various measures are implemented to safeguard aluminum coils against dust and dirt during storage, guaranteeing their quality and preventing potential damage. One commonly employed technique involves securely wrapping the coils with protective coverings, such as plastic or polyethylene sheets, effectively creating a barrier against dust and dirt particles. These coverings are usually sealed tightly to prevent any entry of contaminants. Besides wrapping, other precautions are taken to minimize the risk of dust and dirt buildup. Storage areas are diligently maintained and cleared of debris to decrease the chances of contaminants settling on the coils. Regular cleaning and maintenance of the storage space are necessary to maintain a dust-free environment. Furthermore, storage facilities utilize proper ventilation and air filtration systems to regulate airborne particles and uphold a clean atmosphere. These systems aid in reducing the amount of dust and dirt that can accumulate on the coils. Proper handling of the aluminum coils during transportation and storage is also crucial to prevent unnecessary exposure to dust and dirt. Employing appropriate handling equipment and techniques, such as using clean gloves and avoiding dragging the coils on the ground, helps avoid the accumulation of contaminants. By implementing these protective measures, aluminum coils can be stored safely and securely, ensuring the preservation of their quality and averting any potential issues arising from dust and dirt buildup.

- Q: I have a couple aluminum baking sheets, and when i wash them, then dry them with a towel, it turns the towel black? why is this? are these still ok to use? Ive been putting one of those silicone baking sheets or parchment paper on the sheets because of this. but i cant really do that with the cake pan. so how do i stop it from doing this?

- Aluminum reacts to anything acid and a lot of dishwashing detergents are on the acidic end of the ph scale and that causes oxidation which is the black stuff you're getting on the towel. I use commercial aluminum baking sheets when I bake. I like their heavy weight, even browning and NO burnt cookie bottoms. Hot water and a tiny, tiny bit of dishwashing detergent works to clean them. The less you expose the sheets to acidic things, the less black stuff you have. To remove it, I just take one of those sponges with a nylon scrub pad that's safe for non-stick cookware and give it a scrub. I don't soak my baking sheets or put them in the water; I put a drop of the dishwashing soap on the sponge, work it into a foam, wash and rinse quickly. Barkeeper's Friend works well on anything the dishwashing liquid won't take off also. It's normal for the type of material it is but what you use to clean them does make the problem worse. If you don't create the black stuff, you don't have the problem.

- Q: What is the difference between aluminum coils and aluminum sheets?

- Aluminum coils and aluminum sheets share the same material, aluminum, but they have distinct characteristics. Firstly, their form and shape differ significantly. Aluminum coils are elongated and wound into a coil shape. They find wide application in construction, automotive, and HVAC industries for purposes such as roofing, insulation, and air conditioning systems. In contrast, aluminum sheets are flat and come in various sizes and thicknesses. They are commonly utilized in aerospace, transportation, and packaging industries for aircraft parts, automotive body panels, and food packaging. Additionally, their manufacturing processes are distinct. Aluminum coils are produced using continuous casting, where molten aluminum is poured into a mold and cooled to solidify into a coil. This technique allows for the creation of long, continuous coils. Conversely, aluminum sheets are typically manufactured through a rolling process. The aluminum is passed through a series of rollers that gradually reduce its thickness until the desired sheet thickness is achieved. Consequently, this method enables the production of flat sheets with specific thicknesses. Furthermore, the applications of aluminum coils and sheets also differ. Due to their coil shape, aluminum coils are suitable for applications that require long, continuous lengths like roofing or HVAC systems. On the other hand, the flat shape of aluminum sheets makes them ideal for applications that necessitate a flat surface, such as panel or component manufacturing. To summarize, the main distinctions between aluminum coils and aluminum sheets lie in their form, manufacturing process, and applications. Coils are elongated pieces created through continuous casting, while sheets are flat pieces produced through rolling. The choice between coils and sheets depends on the specific requirements of the application at hand.

- Q: Is it possible to utilize aluminum coils for the storage of food items?

- <p>Yes, aluminum coils can be used to store foodstuffs, particularly in the form of aluminum foil. Aluminum foil is a common food storage material due to its properties such as being lightweight, flexible, and providing a barrier against air and moisture. It is often used for wrapping food for cooking, freezing, or preserving. However, it's important to ensure that the aluminum does not react with the food, especially acidic foods, as this could lead to contamination. Additionally, it's not recommended for long-term storage as it does not provide a complete seal or barrier against all contaminants.</p>

- Q: Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that is often used in the construction industry for its versatility and aesthetic appeal. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for architectural cladding applications. One of the key advantages of using aluminum coils for cladding is their resistance to corrosion. Aluminum naturally forms a protective oxide layer, which helps to prevent rusting and deterioration over time. This makes aluminum a long-lasting and low-maintenance option for architectural cladding. Additionally, aluminum coils offer a wide range of finishes and colors, allowing for greater design flexibility. They can be painted or coated to match any architectural style or design concept, making them a popular choice among architects and designers. Furthermore, aluminum is an environmentally friendly material. It is fully recyclable and has a much lower carbon footprint compared to other cladding materials like steel or concrete. This makes aluminum coils a sustainable choice for architectural projects. In summary, aluminum coils are indeed suitable for architectural cladding due to their durability, resistance to corrosion, design flexibility, and environmental benefits.

- Q: How are aluminum coils protected against transportation damage?

- Aluminum coils are protected against transportation damage through various measures implemented by manufacturers and transportation companies. First and foremost, aluminum coils are usually packaged and stored in sturdy crates or pallets that provide a protective barrier against external impact and ensure stability during transit. These crates are often made of wood or metal and are designed to withstand the rigors of transportation. To further safeguard against damage, the coils are often wrapped in protective materials such as plastic or stretch film. This additional layer of packaging helps to prevent scratches, abrasions, and moisture damage during handling and transportation. The coils may also be secured within the crates or pallets using straps or bands to prevent movement and potential impact with other objects. Furthermore, manufacturers often utilize padding materials such as foam or cardboard inserts to create a cushioning effect within the packaging. These inserts help absorb shock and vibration during transit, reducing the risk of damage caused by impacts or sudden movements. Additionally, transportation companies play a crucial role in ensuring the safe transportation of aluminum coils. They employ specialized handling equipment such as forklifts or cranes to minimize the risk of mishandling and dropping the coils. Moreover, they carefully load and secure the coils within shipping containers or trucks, ensuring they are properly braced and immobilized to prevent shifting or rolling during transportation. In summary, aluminum coils are protected against transportation damage through the use of sturdy packaging, protective wraps, padding materials, and appropriate handling techniques. These measures aim to minimize the risk of scratches, dents, and other forms of damage caused by impacts, vibrations, or mishandling during transit.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils, in order to safeguard them and avoid any harm, are typically stored and transported in a manner that guarantees their protection. They are commonly stored in a warehouse or storage facility, maintaining a vertical position to prevent any bending or warping. Regarding transportation, specialized coil trailers or flatbed trucks are often utilized to transport aluminum coils. These trailers are designed specifically to securely hold the coils in place during transit. Straps or bands are typically employed to fasten the coils tightly, preventing any movement or shifting while on the road. Furthermore, it is customary for aluminum coils to be enveloped in protective materials such as plastic or cardboard during transportation. This extra layer of protection serves to shield the coils from moisture, dirt, and other potential hazards. It is of utmost importance to handle aluminum coils with caution to avoid any damage, as even minor dents or scratches can impact their performance. Hence, employing appropriate storage and transportation methods is vital to ensure that the coils reach their destination in optimal condition.

- Q: Is it safe or effective to use a hot plate for heating an aluminum coil?

- <p>Yes, you can use a hot plate to heat an aluminum coil, but with caution. Aluminum is a good conductor of heat, so it will heat up quickly. Ensure that the coil is clean and free from any residues that might cause uneven heating or damage. Monitor the temperature closely to prevent overheating, as aluminum can warp or melt at high temperatures. Use a heat-resistant surface or a heat diffuser to distribute the heat evenly and protect the hot plate surface. Always follow safety guidelines and manufacturer recommendations for both the hot plate and the aluminum coil.</p>

- Q: Can aluminum foil coil be stores for a long time?

- It is ok within one or two years, but for five or six years, it will be oxidized.

- Q: Are aluminum coils suitable for decorative purposes?

- <p>Yes, aluminum coils can be used for decoration. They are lightweight, durable, and corrosion-resistant, making them ideal for various decorative applications. Aluminum coils can be shaped and colored to suit different design needs, often used in architectural features, interior design elements, and even in art installations. Their versatility and aesthetic appeal make them a popular choice for both commercial and residential decoration.</p>

Send your message to us

Flat Rolled Aluminum Coil Indiana - PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords