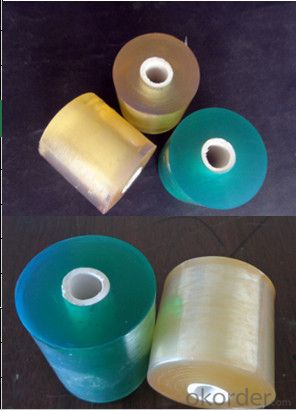

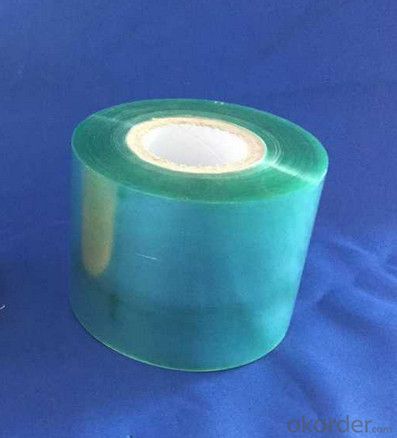

PVC Plastic Wrap Film on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Wrap Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: Wood composite doors, plastic film paste on how to deal with?

- Preparation tools: hair dryer (with hot air), 1 steel wire ball (slightly thinner wire), 1 bottles of white wine, 2 pieces of dishcloth

- Q: What is the function of the plastic film on the refrigerator cabinet?

- Because the SIEMENS refrigerator is in the refrigerator on both sides of the refrigerator, this layer of film will be blocked, the outer layer of film can effectively protect the appearance of the refrigerator, not quality problems, can rest assured that the use of! The ` `

- Q: Do I need to tear the plastic film of the barrel washing machine?

- Of course, wrinkling, housing, affect the appearance, but after the water into the middle membrane and shell, the film is not breathable, easy to cause the casing corrosion, which will be removed.

- Q: New car tires have a transparent plastic film, will not be a problem car, new tires, or the car is the same when you leave the factory?

- Tire manufacturers in the purchase, some luxury cars in order to reflect the overall appearance of the car, the tire has a layer of transparent plastic film dirty material is to prevent dust, as long as four tires are new tyres, front two sign must be the same, and wear are the same

- Q: Is it good to use PP bag or plastic film?

- With asbestos mesh (general dish pack more use of this media) direct contact with the disk, the relative effect is better

- Q: What happens when the friction coefficient of PE plastic film becomes larger?

- The above reasons will cause difficulties when pulling the material bag, bags and bags of different lengths have electric eye deviation, open issues is not good, when the gas nozzle for blowing open bag packing bag for a long time and stuck together.

- Q: Is it possible to lay a plastic film between the roof slab and concrete for waterproofing purposes?

- The roof is waterproof, or it is recommended to use professional waterproof material to do, in the prefabricated board paving finished, first with ordinary cement mortar leveling the ground, and then start waterproof.Roof waterproof, it is recommended to use rigid waterproof + flexible combination of waterproof construction. Thus, the utility model not only has the advantages of firm adhesion of the base surface, strong puncture resistance, high strength, but also can resist the stretching deformation of a certain extent of the base surface, and can meet the waterproof requirement of the roof for long time to be exposed to sunlight, rain and erosion.The specific construction method is to brush K11 waterproof slurry, flexible type, and then do a mortar waterproof agent protection layer, so that it can achieve good waterproof effect!Special reminder, the standard construction is a guarantee of good results, so must be in accordance with the requirements of standard construction, brushing thickness, height, interval time, etc., need attention.

- Q: Rigid plastic film problems

- Many PE film data, there are many PE film and printing bag friends, many of them are in the forefront of the operator, responsible for technology. Liquid has many PE particles, including low density, metallocene, linear and so on

- Q: What is a water-soluble plastic packing film?

- On the degradation mechanism of polyvinyl alcohol, has water and biological degradation characteristics of two kinds of first, soluble in water to form a gel into the soil, increase soil mass viscosity and permeability and water retention, especially suitable for sand transformation. In the soil of PVA by soil bacteria isolated from a single cell (Pseudomonas - strain) decomposition. At least two kinds of system composed of commensal bacteria can degrade polyvinyl alcohol: an active bacteria bacteria is polyvinyl alcohol, the other one is to produce PVA active bacteria substances required for bacteria. The oxidation of secondary alcohols catalyzed by polyvinyl alcohol, then enzymatic hydrolysis by cutting the main chain of PVA, further oxidation degradation, eventually for CO2 and H2O. degradation

- Q: How to make a round hole in plastic film

- If it is a single film, according to the size of the round hole, such as round cans (middle cut) hollow metal objects after heating at the punch press in. It's easy to make a round hole.

Send your message to us

PVC Plastic Wrap Film on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords