High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Specifications of High Quality PVB Film :

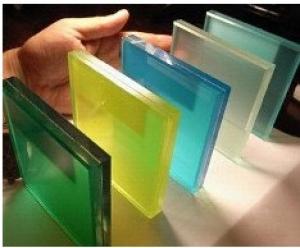

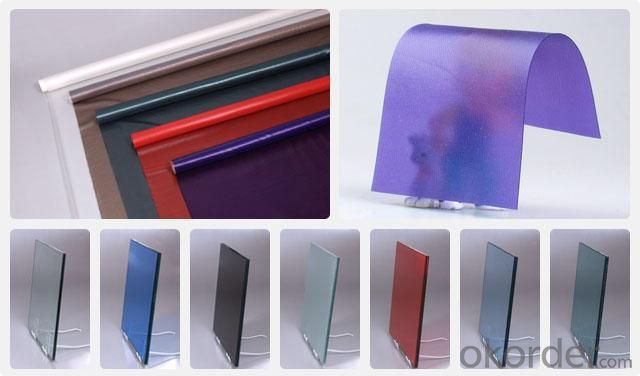

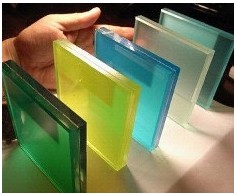

Polyinyl butyral film is made from PVB resin with plasticizer and prepared by the technology of extrusion and calendaring.

I t can be used as the inner layer of sandwich safety glass of cars, locomotive, airplane, tanker, naval vessel etc. It can also be used

as solid adhesive for safety glass, safety mask, building glazing, composite steel plate, etc. It conforms to the enterprise standard of

Q/GHAD 18-2008 .

TDS Of High Quality PVB Film

Item | Value | ||||

E-413J | E-413A | E-413B | E-413C | ||

Volatile content % ≤ | 2.0 | 2.0 | 2.0 | 2.0 | |

Tensile Strength MPa ≥ | 20.0 | 20.0 | 15.0 | 15.0 | |

Elongation @ Break % ≥ | 160 | 150 | 150 | 120 | |

Adhesive Strength MPa ≥ | 8.0 | 7.0 | 5.0 | 4.0 | |

Light Transmission Rate % ≥ | 81.0 | 80.0 | 80.0 | - | |

Fog % ≤ | 0.60 | 0.80 | - | - | |

Colourith% ≥ | 75 | 75 | 70 | - | |

Humid Heat | At 70±2, hum.91%-99%.After 48 hrs, sample no change. | At 60±2,hum. 91%-99%.After 8 hrs, sample no change. |

- | ||

Heat-Resistance | At 70±2,After 48 hrs, sample no change. | At 60±2,After 8 hrs, sample no change. |

- | ||

Cold-Resistance | At -55±2,After 48 hrs, sample no change. | At -55±2,After 8 hrs, sample no change. |

- | ||

Light-proof | Light transmission rate decrease less than 2% under 750W light-source, 100hrs | ||||

Usage of High Quality PVB Film :

With the Featurers of Transparent, heat- resistant, cold -resistant, wet-proof, high elasticity, without impurities, good softness, smooth surface with some roughness, good tensile strength and elasticity , the PVB Film can be widely used in Architecture and others.

Packing of High Quality PVB Film :

Vacuumed by aluminum foil and put into wooden cases , 10 Tons /20 FCL or as customers ' requiements .

- Q: What are the choices of plastic film and plastic film in greenhouse?

- The development of greenhouse horticulture has put forward new performance requirements for film greenhouse covering materials. Since 1990s, the three layer co extrusion blown PE film has been developing rapidly in our country. The maximum film width is 12~20m, and the mechanical properties are good. By adding anti-aging agent, anti dew drops and insulation in the resin masterbatch, lack of change the original ordinary PE thin film in the anti-aging, anti dew and heat preservation performance, to better meet the requirements of production in greenhouse.

- Q: How much is plastic waste film?

- In addition, this is mainly sold according to tons, probably thousands of dollars / ton, specifically to see the market, if in accordance with the Jin count, it is probably a few cents a pound, and now waste prices are generally not too high.

- Q: Is there any material in the strong film made of plastic material which is resistant to high temperature, piercing, and has high tensile properties and can not tear off the film?

- The LLDE film may be dedicated to heavy packaging, pierce resistant, tear resistance, tensile, and high temperature resistance depends on what degree requirements, the general level is possible, to have a high temperature resistant performance of plastic is not practical.

- Q: What are the factors affecting the permeability of plastic film?

- Water column height. In the water permeability test, the water quantity in the water cup is changed, indicating that the water column height has no influence on the test result, so the water quantity is not strictly controlled, and the amount of the water can be poured into the water permeable cup with proper amount of water.

- Q: How many kinds of plastic film specifications are there in the greenhouse?

- Colored plastic film colored plastic film is a kind of plastic film with various colors respectively, can also be regarded as a change of light quality plastic filter, it is opaque, can also be a transparent transparent transparent colored film. The rate of around 80%, mainly in red, orange, yellow, green, blue purple and other colors, color film is mainly covered with black opaque film.The application of colored plastic film in agricultural production in China is not long, but from the result of the experiment, compared with the colorless plastic film, with the increase of crop yield, crop quality improvement, reduce plant diseases and insect pests. For example, purple film production, delayed progress bolting, extend the season effect on spinach? Rice seedling cultivation with strong blue film with a colorless film more than cultivating strong short plant, in English, a valley is also heavier in tobacco after planting, covered with black film, can inhibit the growth of weeds, the seedlings of a good marriage, and so on.

- Q: What's the thickness of plastic film 5C?

- The thickness of the film is 0.5 mm, the plastic film 5C model bubble film is based on high pressure polyethylene as the main raw material, and then add brighteners, openings and other accessories, by 230 degrees or so high temperature extrusion Blister Blister products.

- Q: What kind of equipment will be used for plastic film production?

- A film made of polyvinyl chloride, polyethylene, polypropylene, polystyrene, and other resins, used for packaging and as a coating. Plastic packaging and plastic packaging products market share was growing, especially the composite plastic packaging, has been widely used in food, medicine, chemical and other fields, especially in food packaging accounted for the largest proportion, such as beverage packaging, frozen food packaging, food packaging, food packaging, food cooking. These products have brought great convenience to people's life.

- Q: What's the packing material for yogurt?

- Yogurt packaging materials are film, paper, multilayer composite materials, plastic bags are mainly PE, PP, PVC, etc., can be packed in cartons.

- Q: PVC and PE plastic film, which can be used as food preservative film?

- Plastic wrap for food should be made of PE. Cannot use PVC. Because PVC does not meet the requirements of food packaging safety.

- Q: Why use plastic film wrapped legs running, weight loss good?

- After drinking and eating, the cells returned to their original form. This results in increased electrolyte loss, fatigue and poor health. Wrap the body with plastic wrap for a long time, so that the skin can not dissipate heat and sweat accumulation in the local, easy to cause eczema, folliculitis and other skin diseases. In addition, the preservative film itself is a chemical, but also prone to skin allergies, causing other potential hazards to the body."

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1988 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Central America; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches