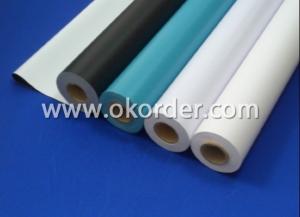

Packing film PVC Stretch Film on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

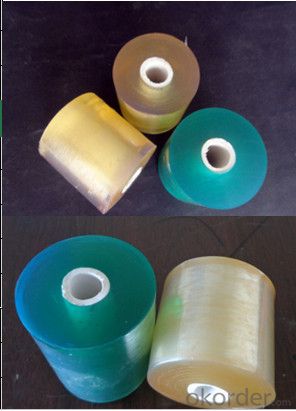

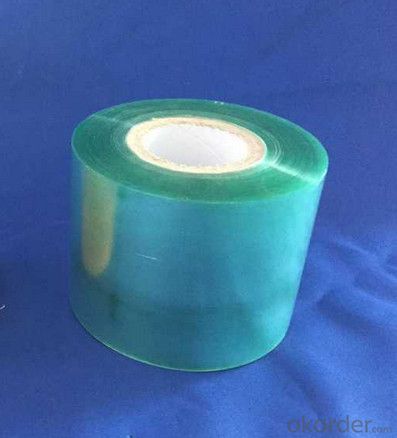

PVC Packing Tape

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: Why do you put plastic film on the paved road?

- It is used for curing concrete. Because cement curing needs proper moisture content, and reacts with moisture to make the hardness of concrete increase continuously.

- Q: What's the function of a thin layer of concrete covered with dirt?

- Cover with plastic film to prevent moisture from evaporating.If the moisture is too fast, evaporation will affect the curing of concrete, it will cause cracking, peeling and other phenomena, affecting the strength of concrete.

- Q: What kind of material is plastic film in greenhouse?

- Multifunctional long-life filmMultifunctional long-life film is added in the process of aging of polyethylene material and amount of surfactants. Multifunctional film Zhejiang Xinguang plastic factory production, 7.5 meters wide, 0.06 mm thick, the service life of a times longer than ordinary film, other than the night shed material high 1 - 2 C. Moreover, the film is not easy to be filled with water drops, has good coverage effect, low cost and high benefit.

- Q: Early spring seedlings using light blue plastic film or white plastic film?

- Use blue film. Because the early growth and development of crops are in a weak period, the impact on the environment is great.

- Q: What is the raw material of agricultural film?

- Agricultural film raw material is HDPE, commonly known as low pressure, buy this kind of raw material, the most important to see your demand, if the amount of big, you can directly find petrochemical agents.

- Q: How many kinds of plastic film specifications are there in the greenhouse?

- PVC and PVC film, polyethylene plastic film and polyethylene film, is currently the largest amount of agricultural production in two kinds of plastic film. The PVC film, because of good comprehensive performance, is China's agricultural production on the popularization and application of the longest time, the maximum number of a polyethylene film is applied in recent years. The varieties, because its superior performance, dosage is increasing greatly,

- Q: How can the weathering of the plastic film on the surface of FRP be removed?

- Flame treatment. Is the use of high temperature flame will burn plastic film of oil and dirt, with the plastic film surface oxidizing flame flame molecular oxidation, decomposition, generating hydroxyl unsaturated double bonds or oxygen containing polar groups, the decomposition of surface molecular chain fracture, plastic film, thus changing the microscopic shape of the plastic film surface, to increase the film surface roughness. In general, the flame surface treatment method has the advantages of short processing time, high speed and good effect, and the treatment effect is stable, and the range of use is wider than that of the spark treatment method. Plastic films or aluminum foils such as PE, PP, PET, PA and Al can handle it. Flame treatment power method of surface treatment, but also on the plastic film on both sides, and the barber non-toxic, no pollution, so it is very suitable for plastic film manufacturers in large production line, film blowing, flow, pull, and synchronized hot film processing.

- Q: Can ultraviolet light penetrate transparent plastic film?

- Depends on what kind of material film, different film on ultraviolet absorption is not the same, and some can absorb all, and some can not

- Q: What is the specific weight of plastic film?

- Low density polyethylene film density of 0.915~0.93 g / cm3; high density polyethylene film density of 0.94~0.96 g / cm3; polypropylene film density of 0.89~0.91 g / cm3; PVC film density of 1.2~1.6 g / cm3.

- Q: What are the appliances for drawing plastic films?

- Samples can be selected according to different products or according to the existing product standards. Under normal circumstances, the larger elongation, try not to use too wide testSample. Any test machine and thickness gauge that can do tensile test and meet the relevant requirements can be used as test instruments and equipment. Operate the test machine according to the specified speed, if there is no gaugeFixed speed, the choice of hard materials at low speed, soft materials choose higher speed. If the specimen is broken beyond the mark line, the sample will be void and the specimen will be re tested.

Send your message to us

Packing film PVC Stretch Film on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches