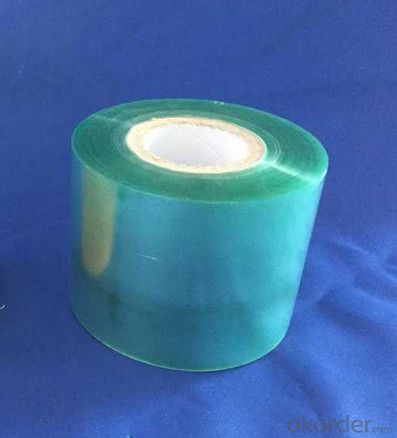

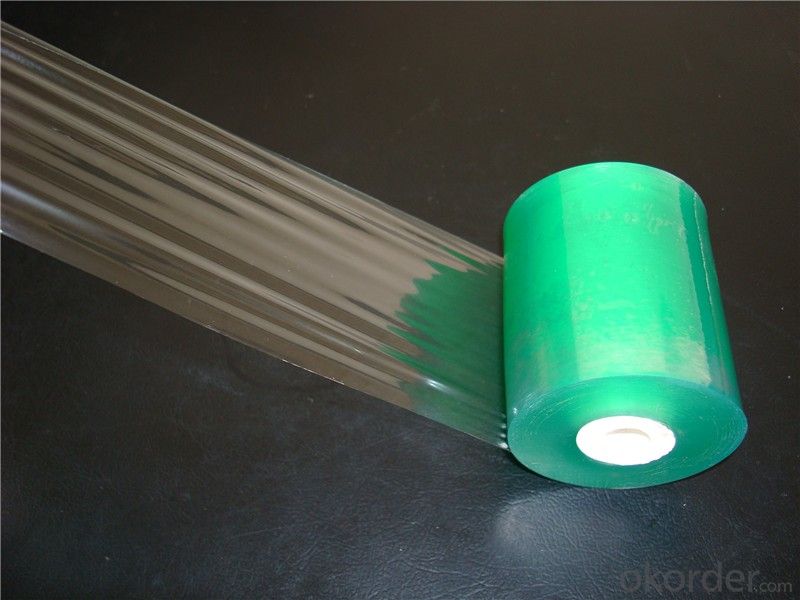

PVC Plastic Wrap Film for Cable and Wires

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC Plastic Wrap Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: Excuse me, where can I buy a special transparent plastic film?

- Different transparent plastic films are needed for the purpose of isolating ultraviolet light from the sun and varying light permeability, such as 50%, 70%, etc..

- Q: Why would you wrap plastic film in a tree?

- Wrapped plastic is to keep moisture, in order to prevent evaporation of water and die plants, and afraid of the wound fungal infection.

- Q: Wood composite doors, plastic film paste on how to deal with?

- Preparation tools: hair dryer (with hot air), 1 steel wire ball (slightly thinner wire), 1 bottles of white wine, 2 pieces of dishcloth

- Q: Should the film on both sides and back of SIEMENS refrigerator be torn off?

- This requires the iron sheet outside there is no shelter, otherwise it will affect the cooling of the condenser, resulting in increased power consumption. So, remove the film from both sides of the refrigerator and the back.

- Q: How is the blow up ratio of a plastic film calculated? What's its formula?

- Well, the draw ratio is the ratio of the annular section area to the cross sectional area of the mandrel between the mandrel and the die. But I don't know the blowing ratio of PE and PO.

- Q: What is the best plastic welding method?

- It must be welding with ultrasonic wave! Because he doesn't need other additives, and the efficiency and welding effects are not artificial. Unless you're a big plastic product.

- Q: Will plastic films refract light?

- Agricultural film is made of ordinary plastic, commonly known as PE film, in high temperature (100 degrees or more), slightly poisonous, good point inside the PE film, added anti ultraviolet material, sunscreen good point (use time will be longer).

- Q: Can damp wood floors be made of plastic sheeting?

- Moisture proof property is the most important technical index of wooden floor. Damp proof floor, in the long heat of the "steam baking", once there is moisture into the floor edge must be warped, causing damage to the floor.

- Q: What are the factors affecting the puncture strength of plastic film?

- The general physical and plastic film thickness, tension, the heat and other factors, but also has a relationship with the processing of materials used in production, if not assured the puncture strength of plastic film is not qualified, can choose the market force commonly used CCY-02 puncture tester to check.

- Q: Can plastic film protect against ultraviolet rays?

- The transparent film itself UV blocking effect is not good, the general need to add other ingredients, such as color masterbatch, metal particles etc..

Send your message to us

PVC Plastic Wrap Film for Cable and Wires

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords