Hot Sale Packing film PVC Stretch Film

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

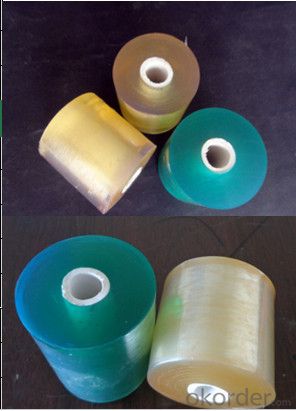

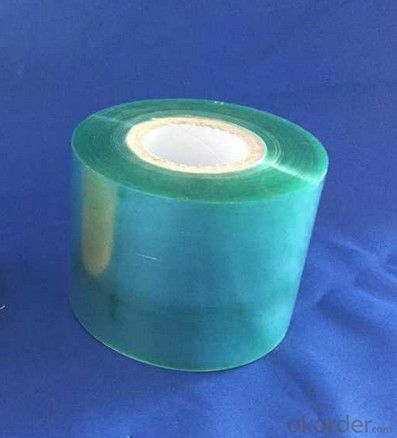

PVC Stretch Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: What's the function of a thin layer of concrete covered with dirt?

- Cover with plastic film to prevent moisture from evaporating.If the moisture is too fast, evaporation will affect the curing of concrete, it will cause cracking, peeling and other phenomena, affecting the strength of concrete.

- Q: Early spring seedlings using light blue plastic film or white plastic film?

- The blue film absorbs light, which is converted to carbohydrates by chlorophyll, and is covered with white film. The light is too strong and the seedlings die easily. Therefore, we should pay attention to the use of choice, so that the healthy growth of seedlings.

- Q: Several forming methods of plastic film and their advantages and disadvantages are summarized

- Tape casting, blown film and calendering, the physical properties of cast films are better than blown films.

- Q: Genuine Clinie mask packaging has no plastic film

- If that is the box, is not only a plastic, paper shell. If it's one of those dozens of pieces sold in one bag, then it's a plastic bag. I just went to Korea on New Year's day. I remember it very well.

- Q: Why do plastic films undergo prepress?

- And, because the gravure printing ink than flexo ink and color more, so the color can be restored more fullness and hierarchy, is more advantage.

- Q: How do you tear the plastic film under your new shoes?

- The new shoes under the plastic film can be directly torn down, and if it is difficult, you can use the blower to the hot air file, blowing for a while, the heat is easy to tear off.

- Q: Would you please put a plastic film on the bottom of the tent and put a plastic film on the top of the tent for lightning protection?

- Rain proof, moisture proof, lightning protection, and no eggsWell, I think that if you are not dead or unlucky, lightning not be split into your head. Then you need to be more careful about what happens to you when the lightning hits another place.

- Q: Plastic film surface corona treatment, the bigger the better?

- The surface tension requirement of the general printing processing film is 38 42dyn; the surface tension of the composite processing film is required to reach 42 -54dyn; the surface tension of the film processed by vacuum aluminizing is not less than 42 50dyn.

- Q: Wrap your legs in plastic film. How soon will they be removed?

- PE: flammable, leave the open flame, continue to burn, with the flame yellow, blue, melting dripping, paraffin flavorPVC: not flammable, from the fire that is extinguished, the flame yellow, down green, accompanied by white smoke, softening and not melting, irritating acid

- Q: Why is plastic film made of hand made paste of composite material?

- Films play two roles, on the one hand, make the surface quality better (the film needs to be laid flat), on the one hand, it is convenient to release and prevent adhesion.

Send your message to us

Hot Sale Packing film PVC Stretch Film

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches