PVC Ceiling Panels Home Depot PVC Gypsum Ceiling / PVC Plaster Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Normal width:1.48M,1.53M,1.83M,2.0M. 2.35 M, 2.5 M

Translucent Film: Max Width 4.0M

Length: 100 M or 150 M per roll , can be customized

Light Weight:200-300g/M2

Guarantee: 10 years

Fire rating: B1 (Chinese Standard)

Tension: Withstand tension of 185kg per square meter

paperfaced gypsum board(square edge),PVC facing+aluminum foil backing,without edges wraped.

2)Size:

595x595 mm 595x1195 mm

600x600 mm 600x1200 mm

603x603 mm 603x1212 mm

605x605 mm 605x1210 mm

3)Thickness:

7.0,7.5,8.0,8.5,9.0,12.0

4)Size tolerance:

Length<±1.0mm Width<1.0mm thickness<±0.5mm< span="">

5)Weight:

7.0mm=5.0Kg/m² 7.5mm=5.4Kg/m² 8.0=5.8Kg/m² 8.5=6.2Kg/m²

9.0mm=6.7Kg/m² 9.5mm=7.1Kg/m² 12mm=9.2Kg/m²

6)Strength:≥100N

7)Features:

Non-fammable B1,in accordance with Chinese Standard GB8624-1997.

Heat insulation,sound insulation,light weight,smoke-insulation,Fireproof,moistureproof.

8)Application:hotels,resturant,shopping malls,theaters dauceries,cinemas,stations,auditoriums offices,sitting rooms,business buildings,electronic workshops,precision apparatus rooms and industial or residential nuildings.

10)Installation:match with ceiling T-bar grid

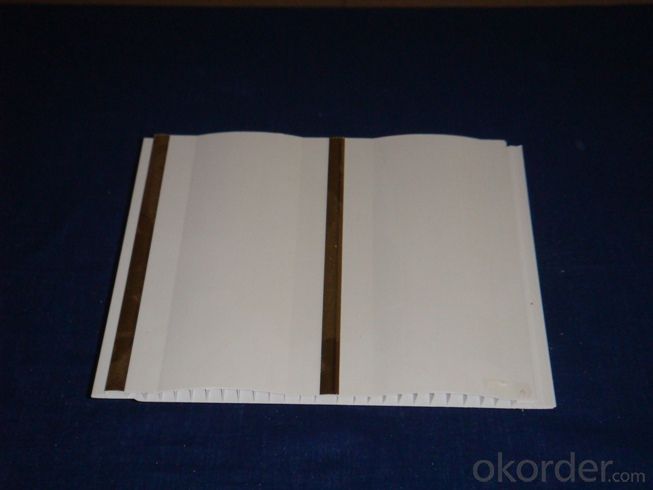

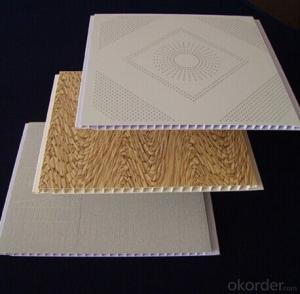

3.Image

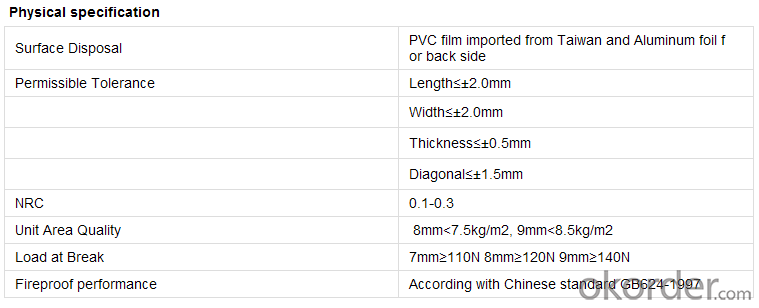

4.Detailed Specification

5.FAQ

Applications

It can be designed with different sizes and styles, widely used for interior ceiling decoration.

Trust us from heart cooperation

Reasonable price

Unique quality

Schedule delivery on time

Updated technology and equipment

Service warmly

1) Commercial & good for decorative

2) Flexible suspension system makes each ceiling tile easily installed and disconnected

3) Easy to match lamps or other ceiling parts

4) Many different pattern

5)PVC film & Aluminum foil back , moisture proof

- Q: Now buy the album inside the page made of PVC board degumming, but also the phenomenon of bubbles, glue is not very sticky, looking for a good reputation, there is a big strength of the manufacturers

- First of all to give you answer the phenomenon of degumming non-stick Most of the PVC pages on the market are hot-melt adhesives, hot-melt adhesives, also known as four seasons, that is, can only be maintained for one year, a year later there will be no glue glue phenomenon, , Containing toluene, the body is not good. Low density will appear bubble deformation. Everbright album page is used with water-based pressure-sensitive adhesive, environmental protection, non-toxic and tasteless, life is not open plastic, sticky, pressurized one night, absolutely no so-called bubble phenomenon. Most of the PVC pages on the market are PP, PS coil, low density (density 1.0), easy to deformation, the board is thin, the same 100 that you know the product density is too small, soft and hard Degree, flatness, use will not work. Density determines the weight, weight determines the price, so you buy the price is certainly low, the quality is also low. Everbright album page is selected PVC sheet, good hardness, high density (density is 1.4), thickness hard, flatness is good, no deformation.

- Q: Pvc board ceiling installation method which know? How much is the installation cost?

- 1, according to the design elevation in the wall around the wall, the ball line should be clear, accurate location, the level of tolerance ± 5mm. 2, along the elevation line fixed edge keel, the role of the keel is the edge of the ceiling seal, side keel commonly used specifications for the 25 * 25mm, the color should be the same with the PVC buckle, the keel with cement nails fixed on the wall. The following are the same as the " 3, to determine the keel position line, because each piece of PVC gussets are already forming decorative panels, generally can no longer cut block, in order to ensure the integrity of the ceiling and installation reliability, according to the size of aluminum plate, and The size of the ceiling to arrange the structure of the ceiling skeleton size. The basic layout of the PVC gusset finishes is: the plate combination to be complete, surrounded by the edge, the edge of the edge to be symmetrical, will arrange the layout of the dragon frame line drawn on the top of the line. The following are the same as the " 4, the main keel hanging point spacing, according to the design recommended series selection, the middle part should be arch, keel arch height is not less than the room surface span of 1/200. The main keel should be installed in time to correct the location and height. To control the formation of the dragon frame, first of all should be pulled out of the vertical and horizontal elevation control line, starting from one end, while the side of the installation to adjust the boom suspension height. To be a large flat, and then some of the curved Alice of a single keel to adjust until the smooth meet the requirements so far.

- Q: PVC safety sign board 2mm thick, tolerance selection part of the mold activity is not affected by the mold or part of the impact of the activities of the class B it? Accuracy without requirements, 1.8mm thick can meet the standard? Please let the big god to explain. thank!

- Tolerances are generally plus or minus 0.1 mm

- Q: Pvc how to heat the deformation of soft board, to make their own shape

- The material is called thermoreversible crosslinking agent, also known as sodium dicyclopentadiene dicarboxylate, in the PVC processing process by adding 0.5%, can make PVC sheet or pipe heated to 50-60 degrees can be free deformation, if you want to return to the original state, but also Can be heated to the original state. This material has memory.

- Q: Pvc floor ok how is it compared to solid wood flooring?

- Pvc floor is the first use of medical infusion bag material - PVC as raw material processing made of. Non-toxic, non-formaldehyde, safe green materials. Pvc floor ok ok Again its advantages are as follows: Long life: the surface after a special nv treatment has a super wear characteristics, life is more than 3 times the traditional wood flooring. Good elasticity: good elasticity has a very good cushioning effect. Play to protect the elderly, the child's safety. Especially in schools, kindergartens, airports and other places where traffic is high. Pvc floor ok ok Color pattern rich: pvc floor has a rich variety of patterns and colors. Especially the color of the sheet pvc floor, his pattern is more diversified, a variety of different patterns of color, realistic imitation wood, marble pattern, carpet pattern and other patterns. Choose from a variety of options Other features: non-slip, fire retardant, waterproof, noise and noise and other characteristics.

- Q: What is PVC material?

- Polyvinyl chloride. Basic features: It is one of the world's largest production of plastic products, cheap, widely used, polyvinyl chloride resin is white or light yellow powder. Depending on the application, different additives may be added, and the polyvinyl chloride plastic may exhibit different physical and mechanical properties. In the polyvinyl chloride resin by adding the right amount of plasticizer, can be made of a variety of hard, soft and transparent products. Pure polyvinyl chloride density of 1.4g / cm3, adding plasticizers and fillers such as the density of PVC plastic parts is generally 1.15-2.00g / cm3. Hard polyvinyl chloride has a better resistance to tensile, bending, compression and impact resistance, can be used alone as a structural material. Soft polyvinyl chloride softness, elongation at break, cold resistance will increase, but the brittleness, hardness, tensile strength will be reduced. Polyvinyl chloride has a better electrical insulation properties, can be used for low-frequency insulation material, its chemical stability is also good. As the thermal stability of polyvinyl chloride is poor, long-term heating will lead to decomposition, release HCL gas, so that PVC discoloration, so its narrow range of applications, the use of temperature is generally between -15 ~ 55 degrees. The main purpose: Because of the high chemical stability, it can be used to make anti-corrosion pipes, pipe fittings, oil pipelines, centrifugal pumps and blowers. Polyvinyl chloride board is widely used in the chemical industry to produce a variety of storage tank lining, building corrugated board, doors and windows structure, wall ornaments and other building materials. Because of electrical insulation performance, in the electrical, electronics industry, for the manufacture of plugs, sockets, switches and cables. In daily life, PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc.!

- Q: PVC plastic hard board maximum temperature how much

- To ask them from the manufacturer, that they give you inside the fire agent. And then the high temperature is not afraid, but a little bit expensive only.

- Q: I use the PVC wall to do the backdrop, there are three square, one centimeter thick PVC board how to fix to the wall, is the use of glue or nails or other methods, with glue what is the glue. It is best to get their own home to the point of advice Thank you

- Pvc board weight is not too large, and only 0.6 square, can be used glass glue pvc board paste to the false wall. First in the pvc board around the diagonal and make a long glass of plastic, and then posted on the wall, surrounded by millet nails or clip fixed, two days after the glass gel dry remove the millet nails or clips can be. Later want to remove the pvc board painting, just use a small blade gently open the viscose of the hole, you can peel down, the wall of the remaining glass glue can also be stripped directly. Are you satisfied with the above?

- Q: With the area and thickness of the KT board and PVC board which is more expensive?

- In general is pvc expensive

- Q: Acrylic board, Abs board and PVC board What is the difference, which can be cut with electric wire?

- The acrylic sheet is a polymethyl methacrylate (PMMA) sheet plexiglass. It is widely used in instrumentation parts, car lights, optical lenses, transparent pipes and so on The Abs plate is an acrylonitrile / butadiene / styrene copolymer plate. Widely used in food industry parts, building models, Shouban production, into the electronic industry components, refrigerator refrigeration industry, electronic appliances, pharmaceutical industry, auto parts and so on. PVC board is a vacuum plastic film. Widely used in chemical, oil, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries.

Send your message to us

PVC Ceiling Panels Home Depot PVC Gypsum Ceiling / PVC Plaster Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords